Crank and connecting rod transmission mechanism and main transmission system of punch

A technology of main transmission system and transmission mechanism, applied in the field of main transmission system, can solve the problems of poor performance stability, inability to adjust, fast friction plate loss, etc., and achieve the effect of increasing flexibility, improving efficiency, and expanding processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

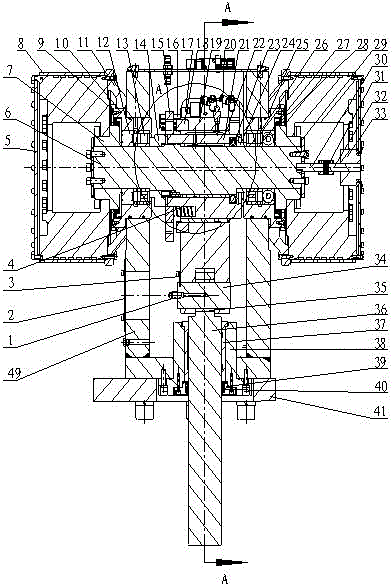

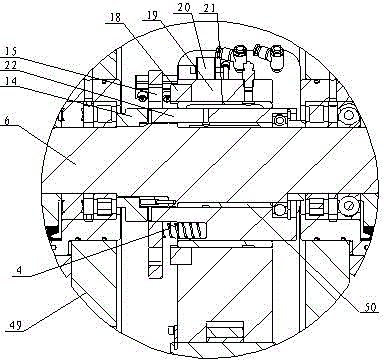

[0026] Embodiment 1: crank-link transmission mechanism with variable eccentricity.

[0027] A crank-link transmission mechanism with variable eccentricity, the transmission mechanism is divided into two different forms, one is a mechanism form with double eccentricity conversion, and the other is a mechanism form with triple eccentricity conversion. Two kinds of transmission mechanism all are to comprise crankshaft 6, connecting rod 19 and eccentric distance variable device, and eccentric distance variable device is made up of fixed tooth nest 14, tooth nest 18, crankshaft eccentric sleeve 22, conversion sleeve 15 etc., fixed The tooth socket 14 is connected to the crankshaft 6 through a spline; the tooth socket 18 is fixed on the connecting rod 19 by screws; slide.

[0028] The crankshaft offset sleeve 22 is set on the crankshaft 6, and the first lubricating copper sleeve 50 is arranged between them to play a role in lubrication. The connecting rod 19 is sleeved on the crank...

Embodiment 2

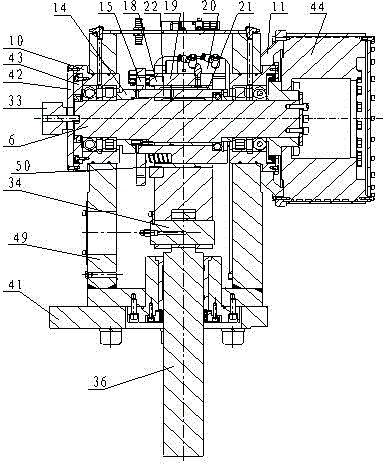

[0035] Embodiment 2: A new CNC turret punch press main drive system powered by CNC single / double servo motors.

[0036] A punch servo main transmission system of a crank-link transmission mechanism with variable eccentricity, including a servo motor connected in sequence, the crank-link transmission mechanism described in Embodiment 1, and the crank-connect rod transmission mechanism described in Embodiment 1. The guide sleeve 37, the slide block 36 and the punch are characterized in that the single / double servo motor 44 is directly connected with the crank-link transmission mechanism described in Embodiment 1, and directly drives the movement of the crank-link transmission mechanism described in Embodiment 1, Drive the work of guide bush 37, slide block 36 and punch that link to each other with the crank-link transmission mechanism, finish stamping action.

[0037] Such as figure 1 , image 3 As shown, the main transmission system of the new CNC turret punch press is power...

Embodiment 3

[0038] Embodiment 3: The main transmission system of a new CNC turret punch press powered by a CNC servo motor and a reducer.

[0039] Such as Figure 4 As shown, the same crank-link transmission mechanism as in embodiment 1 and the servo motor control system similar to embodiment 2 are used, and the structure of the reducer is added. Connect the crank-link mechanism described in Embodiment 1, the speed reducer 47 and the servo motor II 48 in sequence. The output torque can be improved by the deceleration of the speed reducer 47, and the torque output ratio is multiplied by the motor output by the reduction ratio; the speed reduction of the speed reducer 47 reduces the inertia of the load, and the reduction of the inertia is the square of the reduction ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com