Installation and control method of hydraulic control butterfly valve control device based on SMART 3

A control device, hydraulic control butterfly valve technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the heat dissipation of electronic components in the controller box, poor anti-vibration performance, and the valve controller cannot be quickly and effectively Problems affecting the safe operation of the steam turbine heating butterfly valve, etc., to reduce the frequency of power cut/supply, prevent the wrong interval and misoperation risk, and maintain the effect of social image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

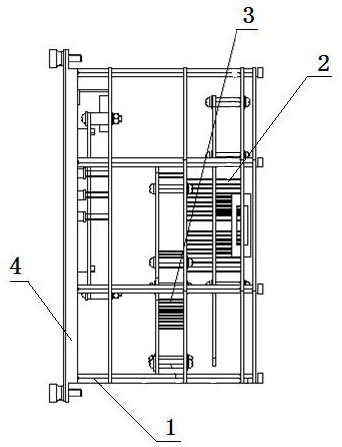

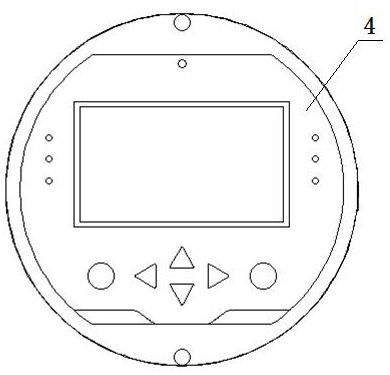

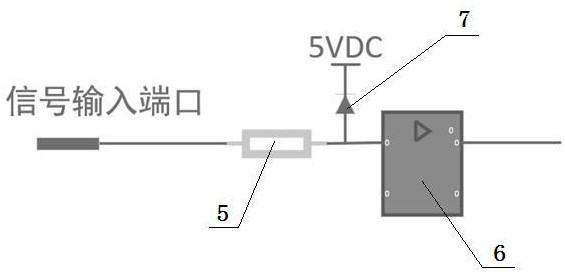

[0027] A hydraulically controlled butterfly valve control device based on SMART 3, which consists of: a support column connection device 1, an EMC device, and is characterized in that: the support column connection device is a frame structure, and terminals are plug-in installed in the lower frame B3, the middle position of the frame is plugged with terminal A2, the end surface of the support column connection device is installed with the control panel 4 and connected by bolts, the terminal A and the terminal B are respectively connected to the electrical system Connection, the signal input port of the EMC device is connected to the diode clamp circuit 5 of the current limiting resistor, and a dual power switch 7 is installed between the diode clamp circuit of the current limiting resistor and the signal amplification circuit 6 .

Embodiment 2

[0029] An installation and control method of the SMART 3-based hydraulic control butterfly valve control device described in Embodiment 1-2, the method is:

[0030] (1) First, install a dual power switch and power indicator on the control device to reduce the frequency of switching / sending power from the power cabinet entering the electronic equipment room, and prevent wrong intervals and misoperations;

[0031] (2) The PDI board, CPU board, and AIO board for the power supply of the valve actuator controller are installed in a stacked frame to enhance the anti-vibration performance of the controller. The terminal A and terminal B connection of the type connection increases the installation space in the control cabinet, increases the heat dissipation space for heat dissipation of electronic components and signal transmission;

[0032] (3) Set the control system to adapt to the ambient temperature at 85°C, the display screen uses an OLED screen with a working temperature of -40~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com