Conical extrusion-shearing type magnetorheological clutch

A shearing, magneto-rheological technology, applied in the direction of fluid clutches, clutches, mechanical equipment, etc., can solve the problem of low transmission torque, and achieve the effect of small volume, compact structure, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

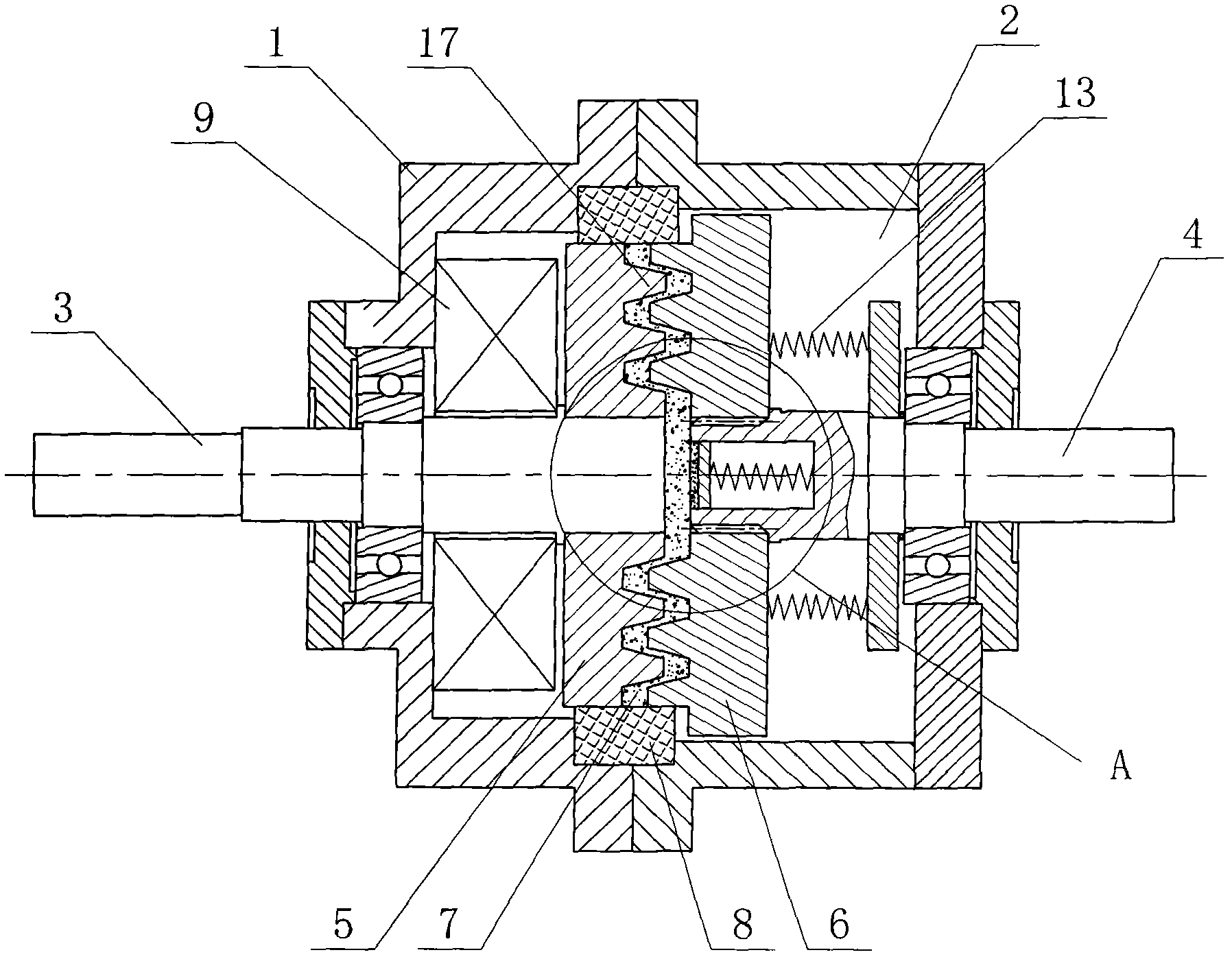

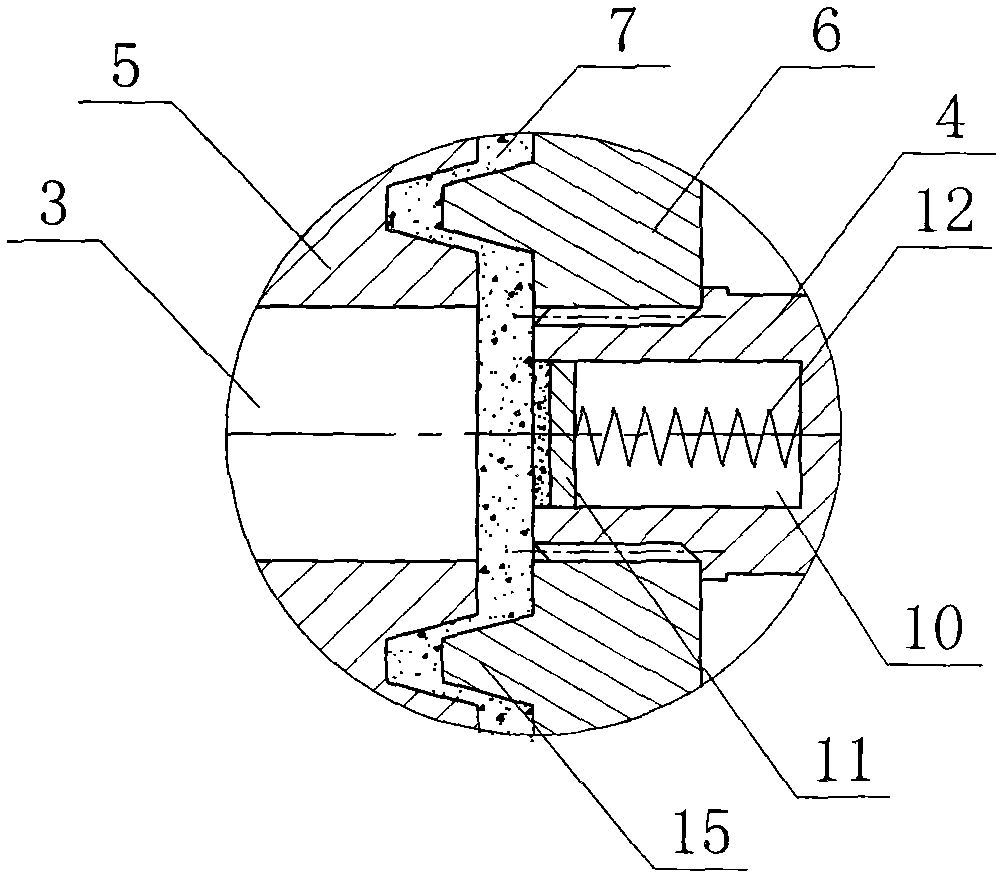

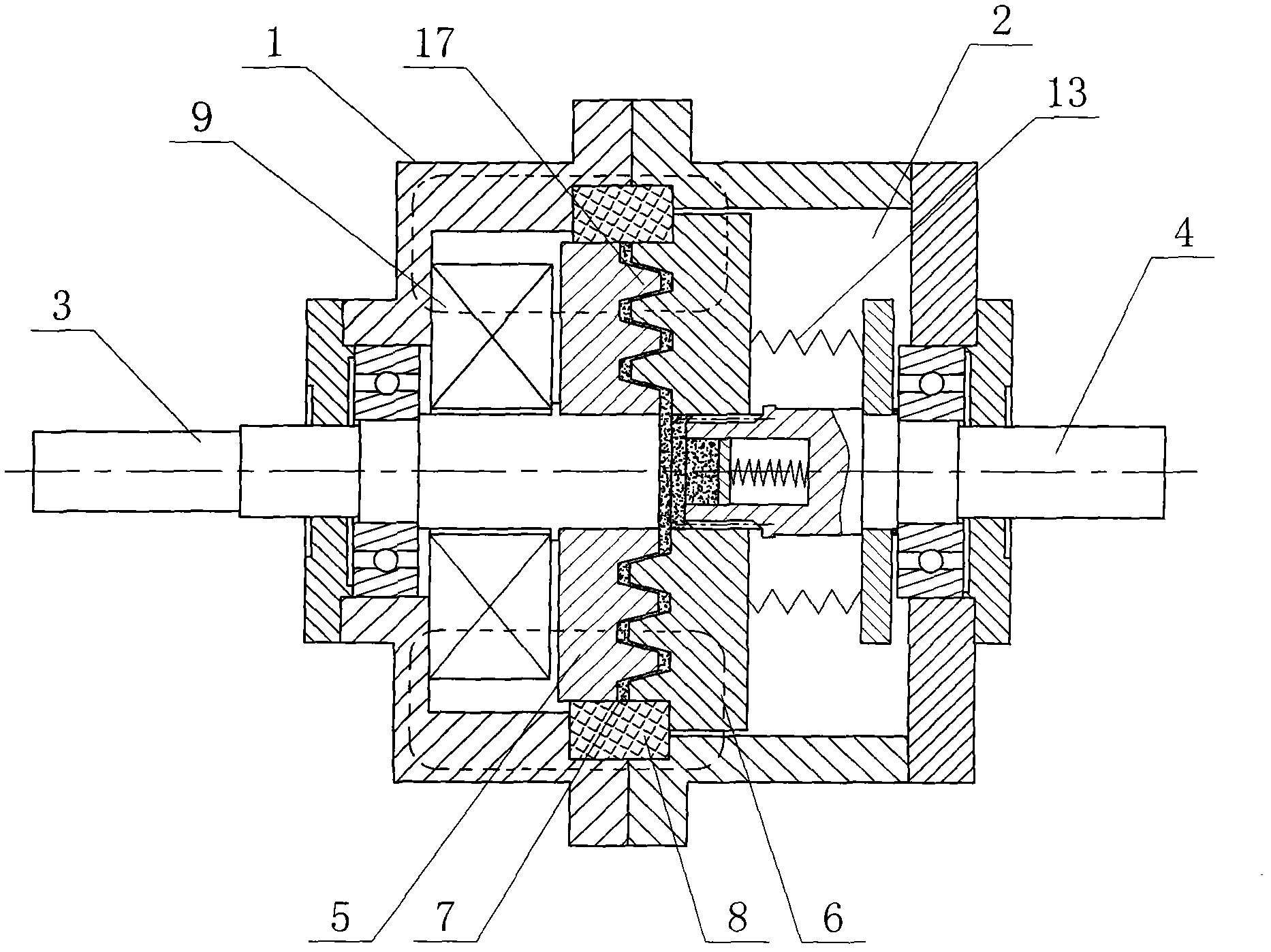

[0026] refer to figure 1 , figure 2 , image 3It is an embodiment of a conical squeeze-shear type magneto-rheological clutch of the present invention. A conical squeeze-shear type magneto-rheological clutch includes a housing 1, and the housing 1 is provided with a working chamber 2, the housing 1 is also provided with an input shaft 3 and an output shaft 4 extending into the working chamber 2, the front end of the input shaft 3 in the working chamber 2 is fixed with an iron core input disk 5, and the working chamber 2 The front end of the inner output shaft 4 is provided with an armature output disk 6 that slides in the axial direction, and a cavity is formed between the iron core input disk 5 and the armature output disk 6, and the magnetorheological fluid 7 is filled in the cavity. The outer periphery of the cavity is provided with a seal ring 8 that seals the magnetorheological fluid 7 in the cavity, and the working cavity 2 is also provided with a coil 9 that drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com