Corrosion inhibitor and its application

A technology of corrosion inhibitor and organic carboxylate, which is applied in the field of corrosion inhibitors, can solve problems that have not been reported and achieve good corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

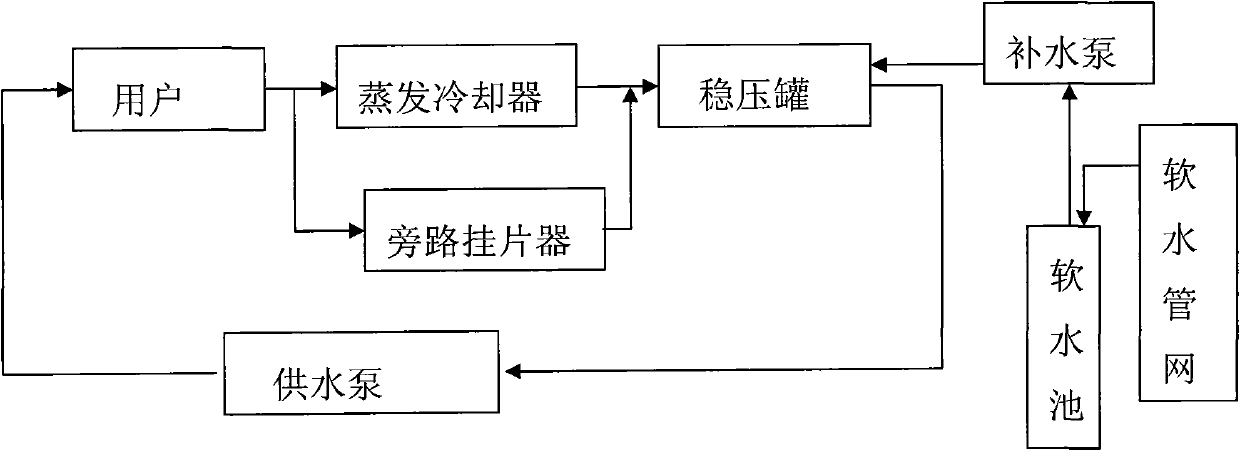

Image

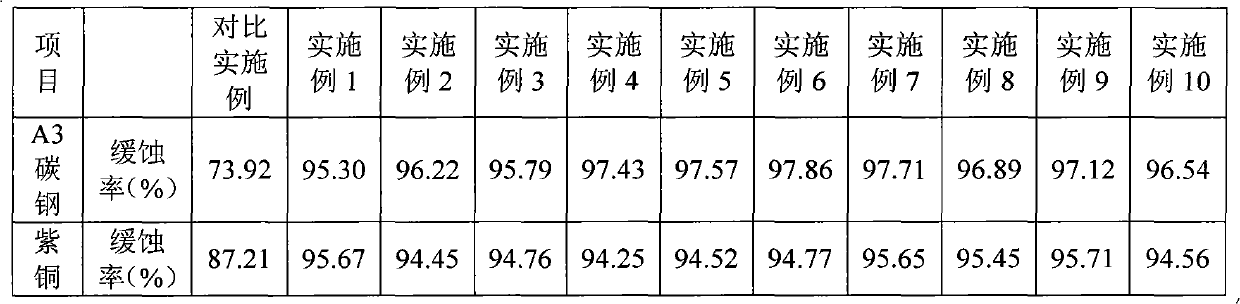

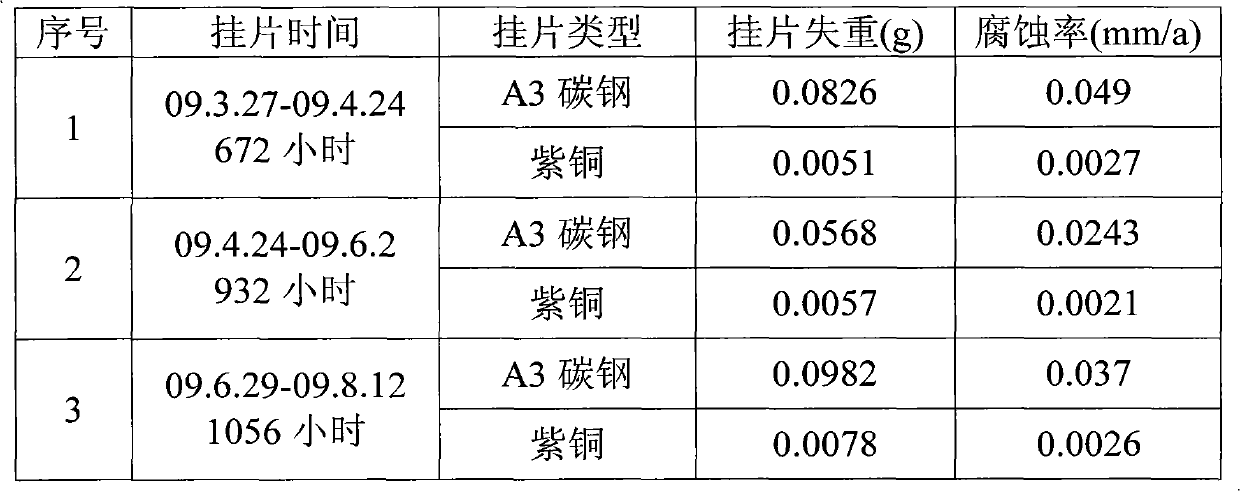

Examples

Embodiment 1

[0027] Corrosion inhibitor formula preparation: 75mg sodium octaborate, 75mg sodium carbonate, 75mg sodium hydroxide, 2.5mg lanthanum nitrate, 150mg sodium benzoate, 100mg sodium citrate, 2.5mg sodium molybdate, 20mg 5-methylbenzotriazine Azole, dissolved in 1L of water, is the corrosion inhibitor of the present invention.

Embodiment 2

[0029] Corrosion inhibitor formula preparation: 60mg sodium tetraborate, 100mg sodium carbonate, 75mg potassium hydroxide, 0.5mg praseodymium nitrate, 150mg sodium benzoate, 100mg sodium gluconate, 4.5mg sodium molybdate, 10mg benzotriazole were dissolved in 1L of water is the corrosion inhibitor of the present invention.

Embodiment 3

[0031] Corrosion inhibitor formula preparation: 60mg sodium tetraborate, 75mg sodium carbonate, 75mg sodium hydroxide, 2.5mg cerium acetate, 150mg sodium citrate, 125mg sodium gluconate, 2.5mg sodium molybdate, 10mg 5-methylbenzotriazine Azole, dissolved in 1L of water, is the corrosion inhibitor of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com