Wind power shaft production technology based on high resistance to fatigue and crack prevention

A production process and wind power technology, which is applied in the field of improvement of the production process of wind power shafts, can solve the problems of unscientific temperature control, difficult water temperature control, excessive quenching and cooling, etc. Achieve the effect of process temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

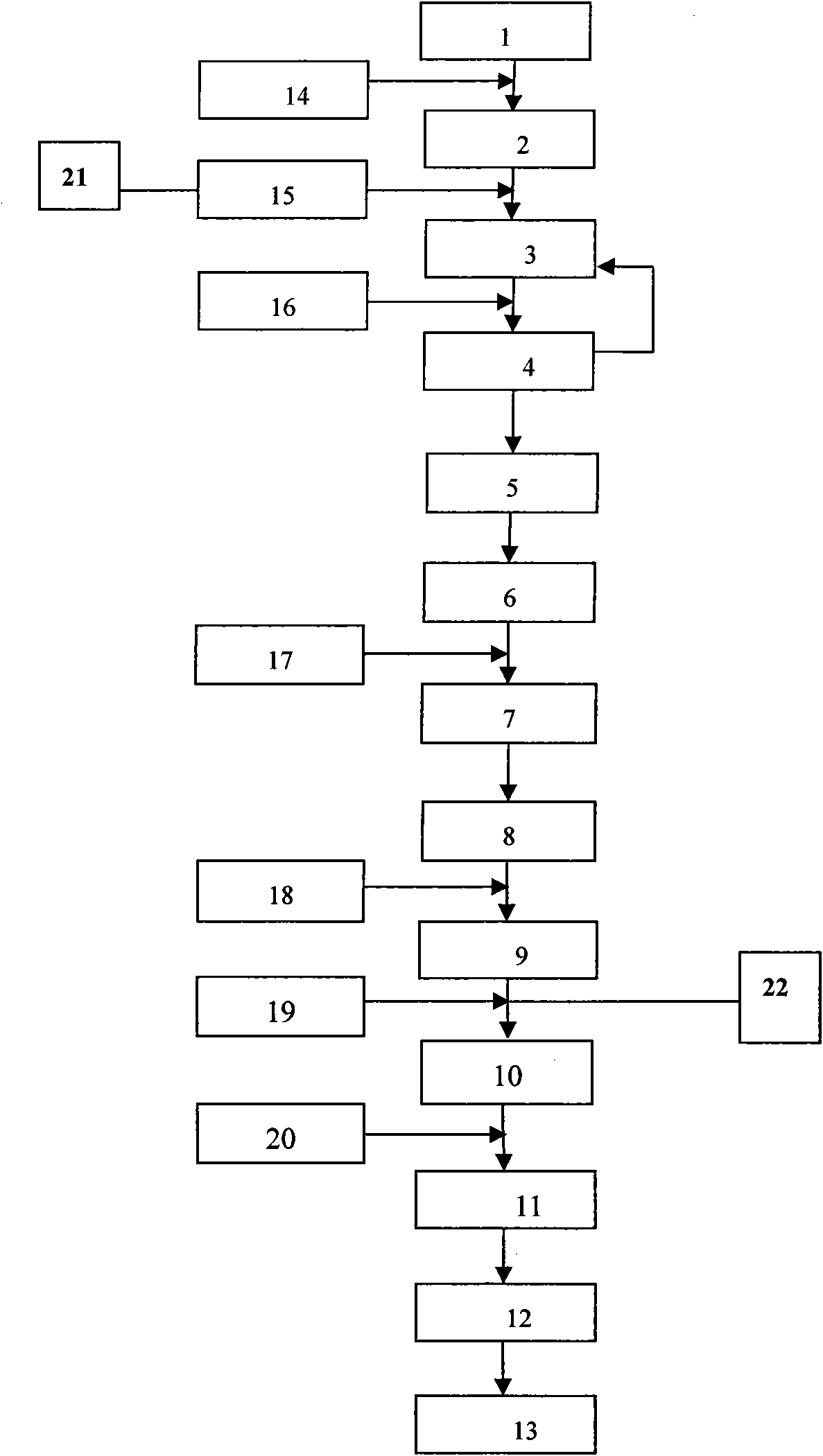

[0022] According to the following process (such as figure 1 ) to produce wind turbine shafts:

[0023] Ingot raw material, blanking, heating, forging, normalizing, tempering, annealing and cooling, inspection and correction, rough machining, quenching, milling, finishing, finished products.

[0024] And when heating, the temperature in the heating furnace is controlled through the heating furnace temperature control system based on fuzzy intelligence, and the water temperature control system based on the SPCE061A single-chip microcomputer is used to control the temperature of the water in the quenching pool during quenching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com