Oil quenching heat treatment process for high-hardness low-chromium multicomponent alloy casting ball

A multi-alloy, high-hardness technology, used in heat treatment equipment, quenching agents, quenching devices, etc., can solve the problems of low impact toughness, high user cost, as-cast structure cannot be changed, etc., to improve the fatigue impact life. , good thermal oxidation stability, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

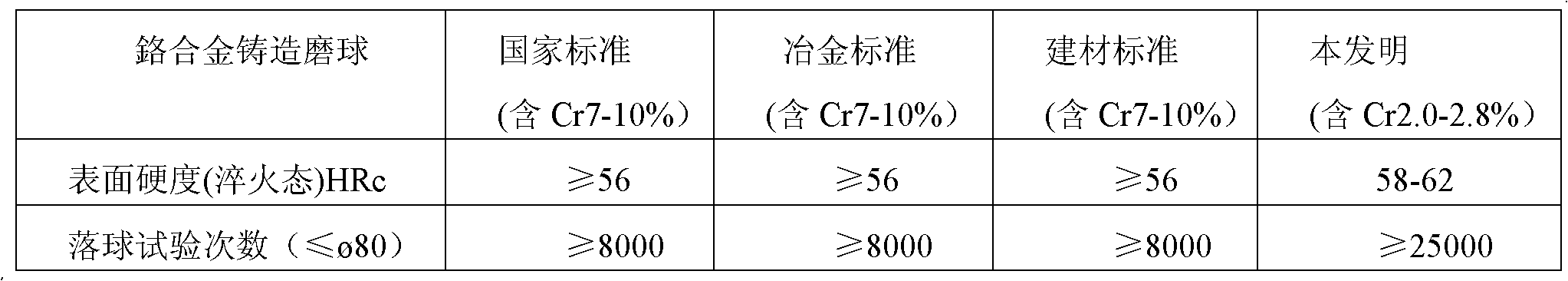

[0028] A high-hardness, low-chromium multi-element alloy casting ball oil quenching heat treatment process, characterized in that: the high-hardness and low-chromium multi-element alloy casting ball contains the following components by weight percentage: C: 1.5-2.0, Mn: 0.3-1.0, Cr: 2.0-2.8, Si: 0.78-0.80, Cu: 0.05-0.055, S: ≤0.02, P: ≤0.03, the matrix is iron; the high-hardness and low-chromium multi-element alloy cast ball adopts oil quenching heat treatment process, and its specific Process steps include:

[0029] a. Put the as-cast high-hardness low-chromium multi-element alloy casting ball just taken out of the mold into the special quenching frame quantitatively, and then put it in the quenching furnace for heating. After heating to 950-1000°C, keep it warm for 2-3 hours ;

[0030] b. Pour the high-hardness and low-chromium multi-element alloy casting balls after heating and heat preservation into the quenching shaker, and then sink into the quenching oil with the que...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com