Prestressed jack seal ring rubber compound and preparation method thereof

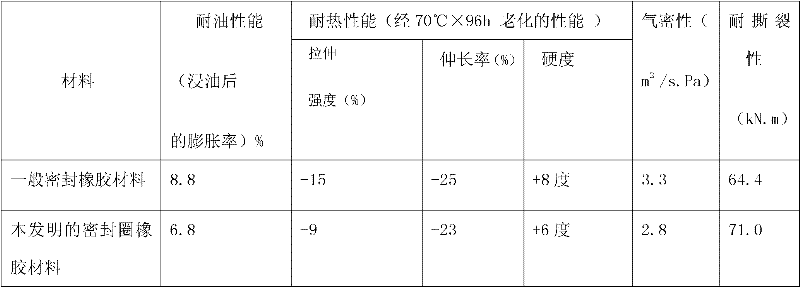

A technology of rubber compound and jack, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of high cost, high price of hydrogenated nitrile rubber and chlorohydrin rubber, and achieve suitable elasticity and good wear resistance , The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Raw material preparation:

[0032] Preparation of raw materials for rubber compound:

[0033] Weigh polyurethane rubber 100, silicone rubber 8, fluorine rubber 5, ethylene propylene rubber 3.5, natural rubber 0.8, sulfur 0.4, zinc oxide 0.5, stearic acid 0.4, antioxidant RD 0.3, antioxidant 4010NA 1, paraffin wax 3, high resistance Mill carbon black N330 63, di-isooctyl phthalate 20, magnesium hydroxide 30, accelerator PZ 1-2,

[0034] Preparation of raw materials for B rubber compound:

[0035] Weigh one-component homopolychlorohydrin rubber 85, co-polychlorohydrin rubber 15, zinc stearate 1, anti-aging agent RD 2, gelatin T-78 0.5, rhine wax 1, carbon black 48, barium sulfate 12, o-benzene Diisooctyl dicarboxylate 7, talc powder 4, sulfur 0.4, vulcanizing agent DCP1.5, accelerator Na-22 2.

[0036] 2. The method for preparing the rubber compound of the prestressed jack sealing ring comprises the following steps:

[0037] The first step: Prepare A rubber materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com