Dry strength agent and preparation method and application thereof

A technology for enhancing dry strength and dry base, which is applied in the direction of strengthening agent addition, etc., can solve the problems that dry strength and folding resistance cannot be satisfied at the same time, achieve low cost, improve dry strength and tear resistance, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

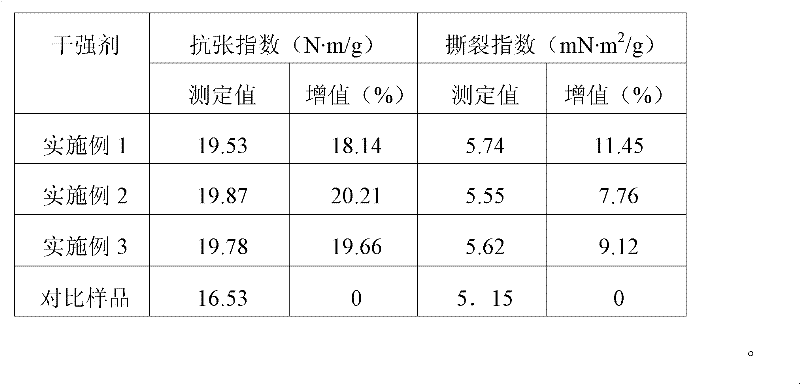

Examples

Embodiment 1

[0023] (1) Activation pretreatment of starch: In a four-necked flask equipped with stirring, thermometer, ventilation pipe and feeding channel, add 475g of deionized water, add 2.5g of sodium hydroxide and 0.75g of urea under stirring, place on ice Cool in a bath, add 25 g of dry base starch, and stir to obtain a homogeneous starch paste with a weight concentration of 5%;

[0024] (2) Heat up to 55°C under stirring, add 0.5g of oxidant sodium persulfate and 1g of 3-chloro-2-hydroxypropyltrimethylammonium chloride, carry out oxidative degradation and cationization, after 4 hours of reaction, A translucent viscous liquid was obtained, and the pH value of the system was adjusted to 7.0 with hydrochloric acid;

[0025] (3) Nitrogen, add 85g of acrylamide, 3g of acrylic acid, 10g of methacryloyloxyethyltrimethylammonium chloride, 2g of methyl acrylate and 6g of initiator ammonium persulfate, heat up to 85°C and react for 2 hours , cooled to 25°C to obtain the dry strengthening age...

Embodiment 2

[0027] (1) Activation pretreatment of starch: In a four-necked flask equipped with stirring, thermometer, ventilation pipe and feeding channel, add 450g of deionized water, add 7.5g of sodium hydroxide and 5.0g of urea under stirring, place on ice Cool in a bath, add 50 g of dry base starch, and stir to obtain a homogeneous starch paste with a weight concentration of 10%;

[0028] (2) Heat up to 70°C under stirring, add 1.5g of oxidizing agent sodium persulfate and 4g of 3-chloro-2-hydroxypropyltriethylammonium chloride, carry out oxidative degradation and cationization, after reacting for 3 hours, A translucent viscous liquid was obtained, and the pH value of the system was adjusted to 7.5 with hydrochloric acid;

[0029] (3) Nitrogen was added, 56g of acrylamide, 2g of acrylic acid, 7g of acryloyloxyethyltrimethylammonium chloride, 3g of methyl acrylate and 3.4g of initiator ammonium persulfate were added, and the temperature was raised to 90°C for 2 hours of reaction. Cool...

Embodiment 3

[0031] (1) Activation pretreatment of starch: In a four-necked flask equipped with stirring, thermometer, ventilation pipe and feeding channel, add 368g of deionized water, add 3.84g of sodium hydroxide and 2.24g of urea under stirring, place on ice Cool in a bath, add dry base starch 32g, stir to obtain a homogeneous starch paste, the weight concentration is 8%;

[0032] (2) Heat up to 65°C under stirring, add 1.6g of oxidant sodium persulfate and 2.56g of 3-chloro-2-hydroxypropyltrimethylammonium chloride, carry out oxidative degradation and cationization, and react for 2 hours , to obtain a translucent viscous liquid, adjust the pH value of the system to 8.0 with hydrochloric acid

[0033] (3) Nitrogen, add 52g of acrylamide, 3g of acrylic acid, 3g of dimethyldiallyltrimethylammonium chloride, 1.8g of methyl acrylate and 2.4g of initiator ammonium persulfate, and heat up to 85°C to react 2 Hours later, cool to 25°C to obtain the dry strengthening agent, the viscosity is 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com