Carbon ramming material for blast furnace and preparation method for carbon ramming material

A carbon ramming material and blast furnace technology, which is applied in the field of carbon ramming material and its preparation, can solve the problems of normal production, poor thermal conductivity and low thermal conductivity that affect the life of the blast furnace, so as to ensure the smooth production of the blast furnace and improve the particle density. The effect of stacking and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

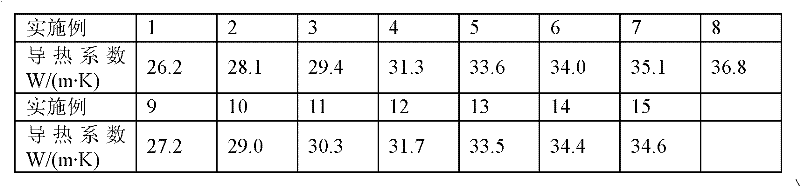

Examples

Embodiment 1

[0018] A carbon ramming material for a blast furnace, which is composed of the following components in parts by weight: component A with a particle size of 0.1 to 5 mm—35 parts of electric calcined anthracite, component B with a particle size of <0.1 mm—natural graphite. 25 parts, 5 parts of corundum with a particle size of <0.1 mm, and 8 parts of thermosetting phenolic resin.

[0019] The electric calcined anthracite is anthracite whose calcining temperature is 1700°C.

[0020] The preparation method of above-mentioned blast furnace carbon ramming material is:

[0021] 1) Mixing: Mix 35 parts of electric calcined anthracite with a particle size of 0.1 to 5 mm, 25 parts of natural graphite with a particle size of <0.1 mm, and 5 parts of corundum with a particle size of <0.1 mm;

[0022] 2) Add 8 parts of thermosetting phenolic resin as a binder, and stir evenly; finished product;

[0023] When in use, carry out ramming construction according to site requirements.

Embodiment 2

[0025] A carbon ramming material for a blast furnace, which is composed of the following components in parts by weight: component A with a particle size of 0.1 to 5 mm—65 parts of electric calcined anthracite, component B with a particle size of <0.1 mm—natural graphite. 55 parts, 16 parts for corundum with particle size <0.1 mm, and 15 parts for thermosetting phenolic resin.

[0026] The electric calcined anthracite is anthracite whose calcining temperature is 1800°C.

[0027] The preparation method of above-mentioned blast furnace carbon ramming material is:

[0028] 1) Mixing: Mix 65 parts of electric calcined anthracite with a particle size of 0.1 to 5 mm, 55 parts of natural graphite with a particle size of <0.1 mm, and 16 parts of corundum with a particle size of <0.1 mm;

[0029] 2) Add 15 parts of thermosetting phenolic resin as a binder, and stir evenly; finished product.

Embodiment 3

[0031] A carbon ramming material for a blast furnace, which consists of the following components in parts by weight: component A with a particle size of 0.1 to 5 mm—45 parts of electric calcined anthracite, component B with a particle size of <0.1 mm—natural graphite. 40 parts, 10 parts for corundum with particle size <0.1mm, and 12 parts for thermosetting phenolic resin.

[0032] The electric calcined anthracite is anthracite whose calcining temperature is 1900°C.

[0033] The preparation method of above-mentioned blast furnace carbon ramming material is:

[0034] 1) Mixing: mix 45 parts of electric calcined anthracite with a particle size of 0.1 to 5 mm, 40 parts of natural graphite with a particle size of <0.1 mm, and 10 parts of corundum with a particle size of <0.1 mm;

[0035] 2) Add 12 parts of thermosetting phenolic resin as a binder, and stir evenly; finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com