Boron-containing nano-mesoporous and macroporous bioactive glass, and preparation method and application thereof

A bioglass and nano-mesoporous technology, which can be used in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problem of lack of drug loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

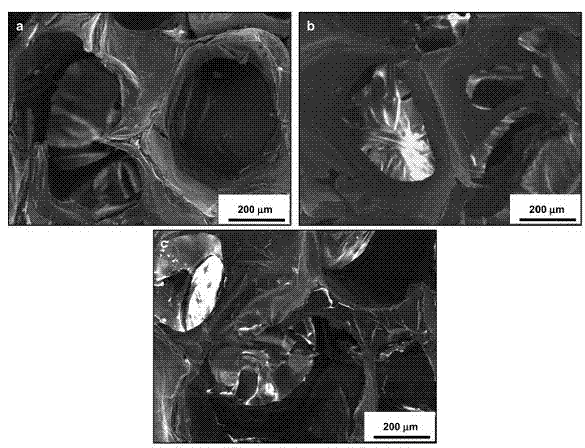

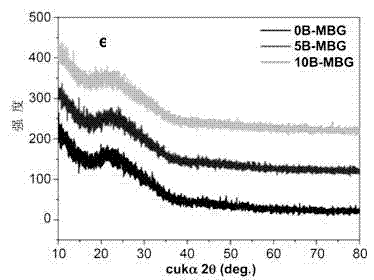

[0040] Example 1 5B-MBG

[0041] The molar ratio of boron source, calcium source, phosphorus source and silicon source is tributyl borate: Ca(NO 3 ) 2 4H 2 O: triethyl phosphate: tetraethyl orthosilicate, the molar ratio is 5:15:5:75, the amount of template added is 1 / 2 of the aforementioned weight, dissolved in 8 times the weight of ethanol, stirred at room temperature for 1 On the second day, the polyurethane sponge (25 PPI) was washed and completely immersed in the solution for 10 minutes, then transferred to a Petri dish, the excess solution was removed, and the rest was evaporated at room temperature for 24 hours. This process was repeated twice to obtain large The porosity of the pore scaffold. After the sample was completely dried, it was calcined at 700°C for 5 hours.

Embodiment 2

[0042] Example 2 10B-MBG 2 times

[0043] The molar ratio of boron source, calcium source, phosphorus source and silicon source is tributyl borate: Ca(NO 3 ) 2 4H 2 O: triethyl phosphate: ethyl orthosilicate, the molar ratio is 5:15:2.5:70, the amount of template added is 1 / 2 of the weight of boron source, calcium source, phosphorus source, silicon source, dissolved in 10 Double the weight of ethanol, stir at room temperature for 1 day, wash the polyurethane sponge (25 PPI) and completely immerse in this solution for 10 minutes, then transfer it to a petri dish, remove the excess solution, and evaporate the rest at room temperature for 24 hours, This process was repeated twice to obtain the porosity of the macroporous scaffold. After the sample was completely dried, it was calcined at 700°C for 5 hours.

Embodiment 3

[0044] Example 3 10B-MBG 3 times

[0045] MBG with 10% boron

[0046] The molar ratio of boron source, calcium source, phosphorus source and silicon source is tributyl borate: Ca(NO 3 ) 2 4H 2 O: triethyl phosphate: tetraethyl orthosilicate, the molar ratio is 5:15:2.5:70, dissolve in ethanol, stir at room temperature for 1 day, wash the polyurethane sponge (25 PPI) and completely immerse in this solution for 10 minutes, then transferred to a Petri dish, the excess solution was removed, and the rest was evaporated at room temperature for 24 hours. This process was repeated 3 times to obtain the porosity of the macroporous scaffold. After the sample was completely dried, it was calcined at 600°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com