Method for thermally synthesizing Cu2ZnSnS4 semiconductor material by solvent through microwaves

A microwave solvothermal and semiconductor technology, used in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of harsh reaction conditions, complicated and difficult processes, and high equipment requirements, achieving fast reaction speed, easy process control, Simple effect of the reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

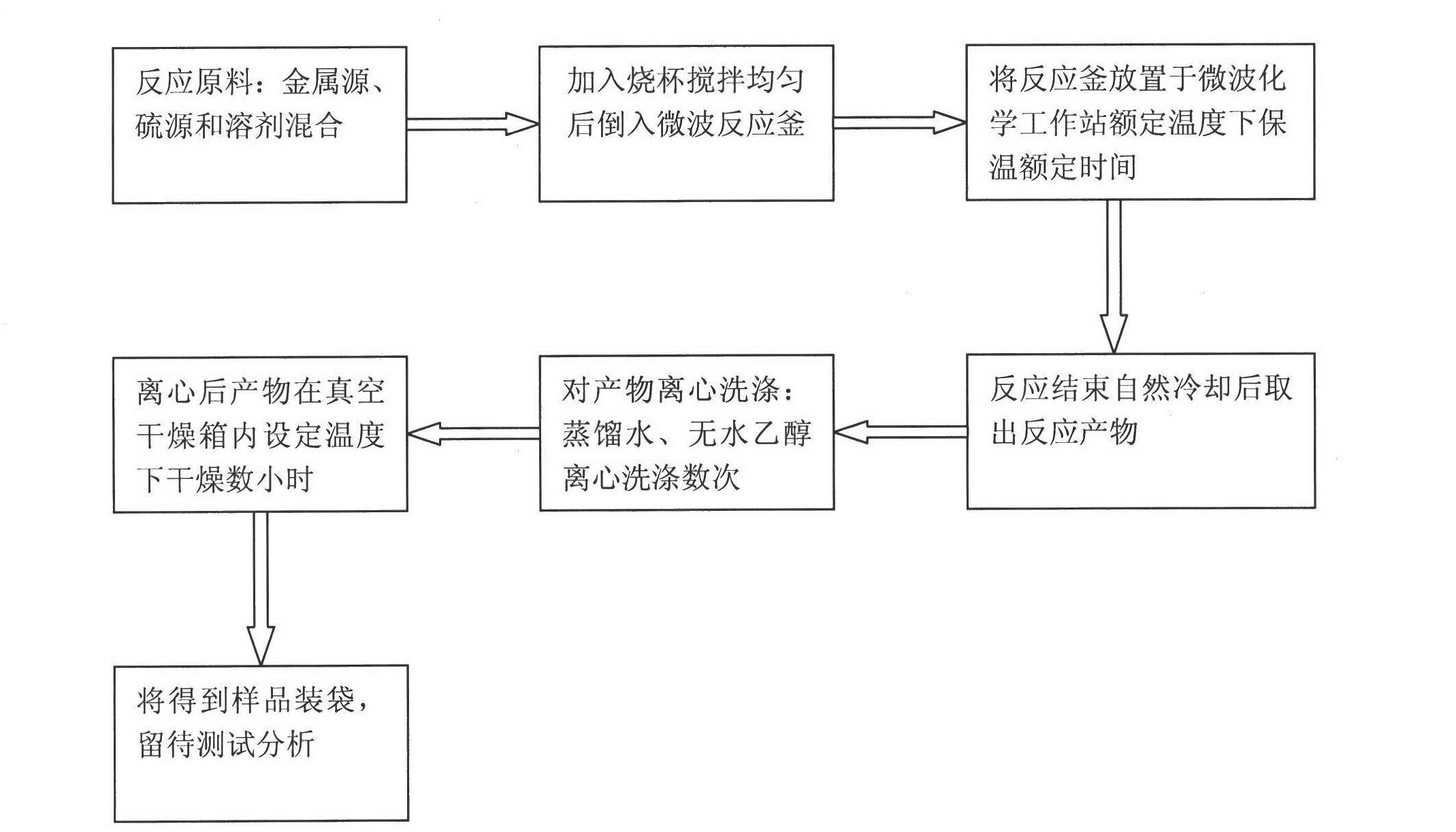

Method used

Image

Examples

Embodiment

[0016] Pour 2.995 grams of copper acetate, 1.642 grams of zinc acetate, 2.628 grams of tin tetrachloride and 2.283 grams of thiourea into a beaker, put a stirring magnet, then add 30ml of ethylene glycol to dissolve, transfer to a magnetic stirrer, and wait for the raw materials to After stirring evenly, pour it into a microwave reactor with a volume of 50ml, install the reaction device, set the temperature at 250°C, and keep it warm for 3 hours. The anhydrous ethanol was centrifuged and washed 3 times, and the product after centrifuged washing was vacuum-dried in a vacuum drying oven at 80° C. for 8 hours. The product was analyzed as Cu by XRD 2 ZnSnS 4 , analyzed by scanning electron microscope, the product is mainly composed of irregular granular powder, the particle size of the granular powder is about 1-2μm, as can be seen from the enlarged picture, the granular powder is composed of many small irregular The flakes are agglomerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com