Novel polymer-based electromagnetic shielding film or sheet and preparation method thereof

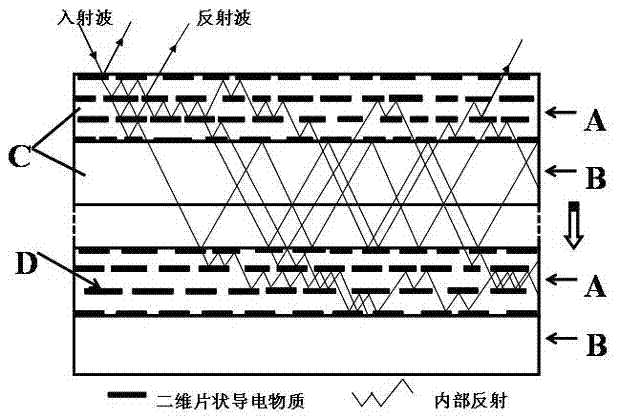

An electromagnetic shielding and polymer technology, applied in the field of polymer-based functional materials and their preparation, can solve the problems of difficult design of morphological structure, low production efficiency, poor shielding effect, etc., and achieves less filler usage, low production cost, and improved effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials are polypropylene and graphite, the aspect ratio of graphite is 10, the insulating layer and conductive layer are pure polypropylene and graphite-filled polypropylene respectively, and the resistivity ratio of insulating layer and conductive layer is 2×10 5 . First, ordinary graphite-filled polypropylene is prepared, and the graphite content is 5%. After the polypropylene and graphite are dried, they are melt-mixed and granulated in a twin-screw extruder. Electromagnetic shielding layer and insulating layer pellets are respectively put into two extruders of the micro-layer co-extrusion device. The extruder speed ratio is 1:1. , The temperature of the layer multiplier and the outlet die is about 200°C. Using three layer multipliers, the melt flows out of the outlet die under the traction of the traction device. After being cooled by the cooling device, the thickness is 2mm and the number of layers is prepared. 16-layer polypropylene based electromagnet...

Embodiment 2

[0029] The raw materials are polypropylene and graphite, the aspect ratio of graphite is 50, the insulating layer and conductive layer are pure polypropylene and graphite-filled polypropylene respectively, and the resistivity ratio of insulating layer and conductive layer is 6×10 6 . Firstly, ordinary graphite-filled polypropylene is prepared, and the graphite content is 10%. After drying the polypropylene and graphite, they are melt-mixed and granulated in a twin-screw extruder. The conductive layer and insulating layer pellets are put into the two extruders of the micro-layer co-extrusion device respectively. The extruder speed ratio is 1:2. The temperature of the layer multiplier and the exit die are both about 200°C. Using one layer multiplier, the melt flows out of the exit die under the traction of the traction device. After being cooled by the cooling device, the thickness is 0.2mm and the number of layers is prepared. 4-layer polypropylene based electromagnetic shield...

Embodiment 3

[0031] The raw materials are polystyrene and nickel sheet, the aspect ratio of nickel sheet is 18, the insulating layer and conductive layer are pure polystyrene and nickel sheet filled polystyrene respectively, and the resistivity ratio of insulating layer and conductive layer is 8×10 6 . Firstly, ordinary polystyrene filled with nickel flakes is prepared, and the content of nickel flakes is 30%. After the polystyrene and nickel flakes are dried, they are melt-mixed and granulated in a twin-screw extruder. The conductive layer and insulating layer pellets are put into the two extruders of the micro-layer co-extrusion device respectively. The extruder speed ratio is 1:1. The temperature of each section of the extruder is controlled between 170-200 °C. The temperature of the layer multiplier and the exit die are both about 200°C. Using 5 layer multipliers, the melt flows out of the exit die under the traction of the traction device. After being cooled by the cooling device, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com