Chemical mechanical grinding device

A technology of chemical machinery and grinding devices, which is applied in the direction of grinding devices, grinding machine tools, grinding tools, etc., can solve the problems of large detection errors, increasing influence, and great influence on measurement results, etc., achieving fast speed and improving The effect of timeliness and fast propagation speed of light waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

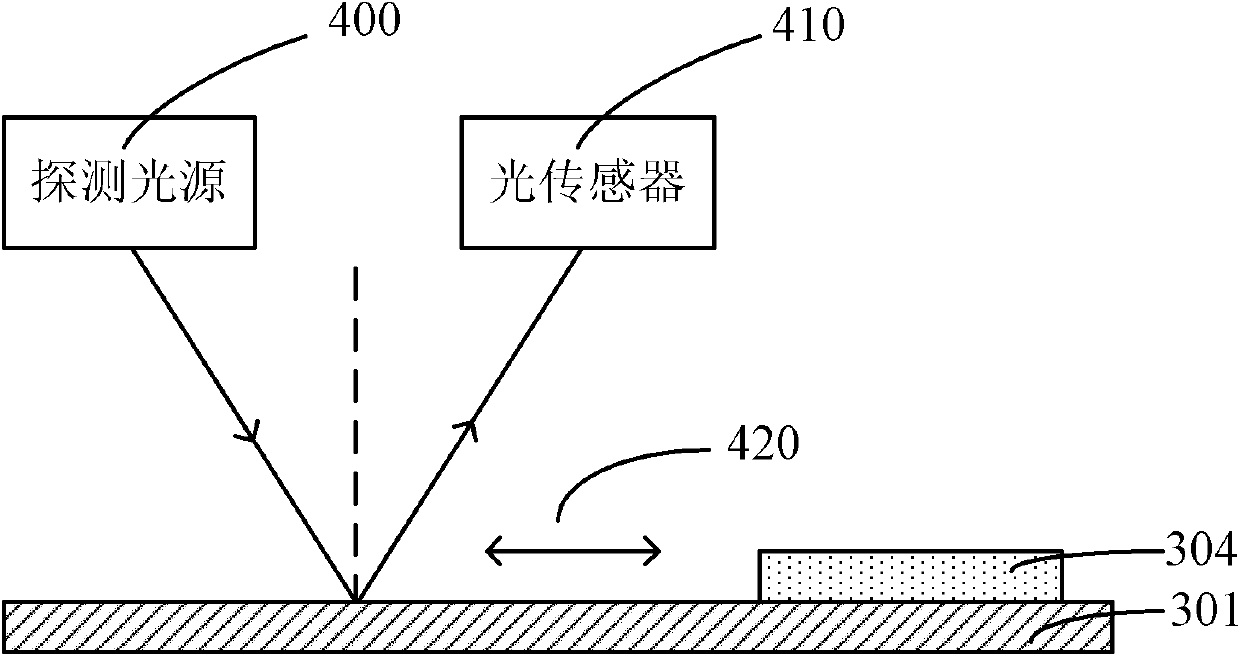

[0035] It can be seen from the background technology that the existing chemical mechanical polishing device has a time delay when detecting the grinding, and as the wafer size increases, the impact caused by the delay becomes more and more obvious; in addition, in order to adopt the existing grinding detection When the device performs grinding detection, a transparent area must be formed on the polishing pad. Because the incident light is incident on the wafer surface through the transparent area, the position and light transmittance of the transparent area have a great influence on the detection accuracy, so it is easy to cause The light transmittance of the projection area is not uniform or the light transmittance is not high enough to affect the detection accuracy. The inventors of the present invention conducted research on the above problems, and provided a chemical mechanical polishing device in the present invention.

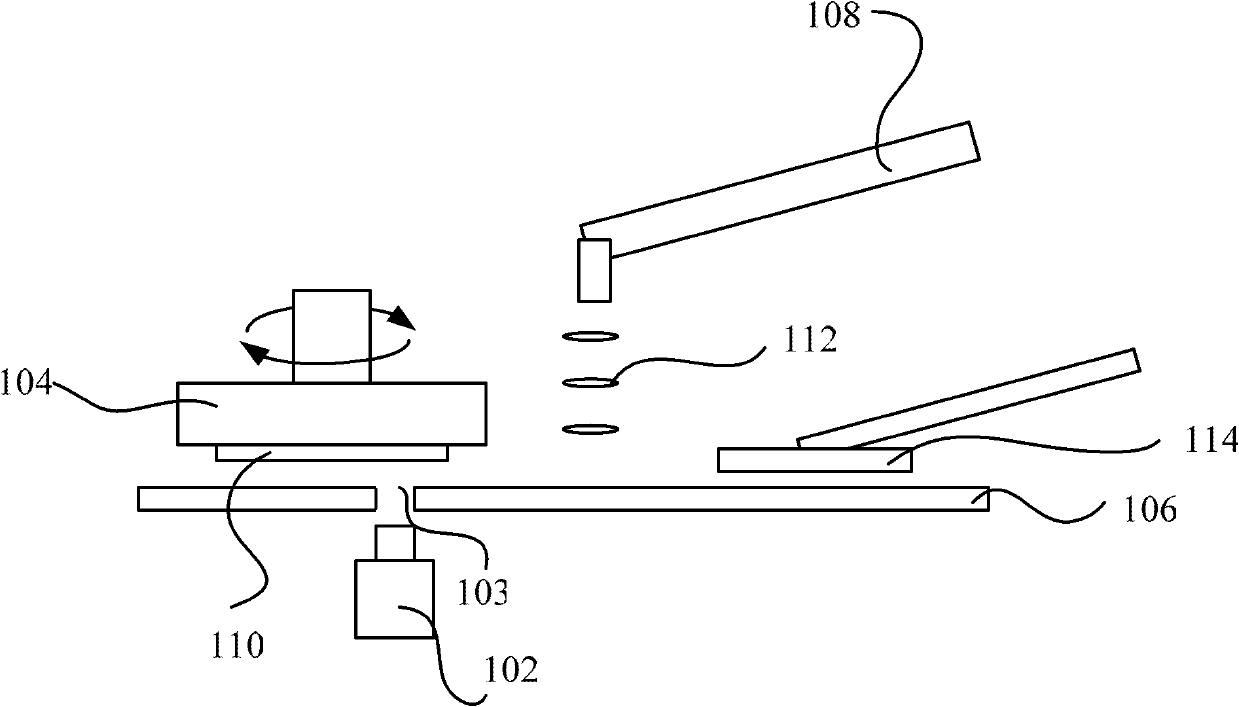

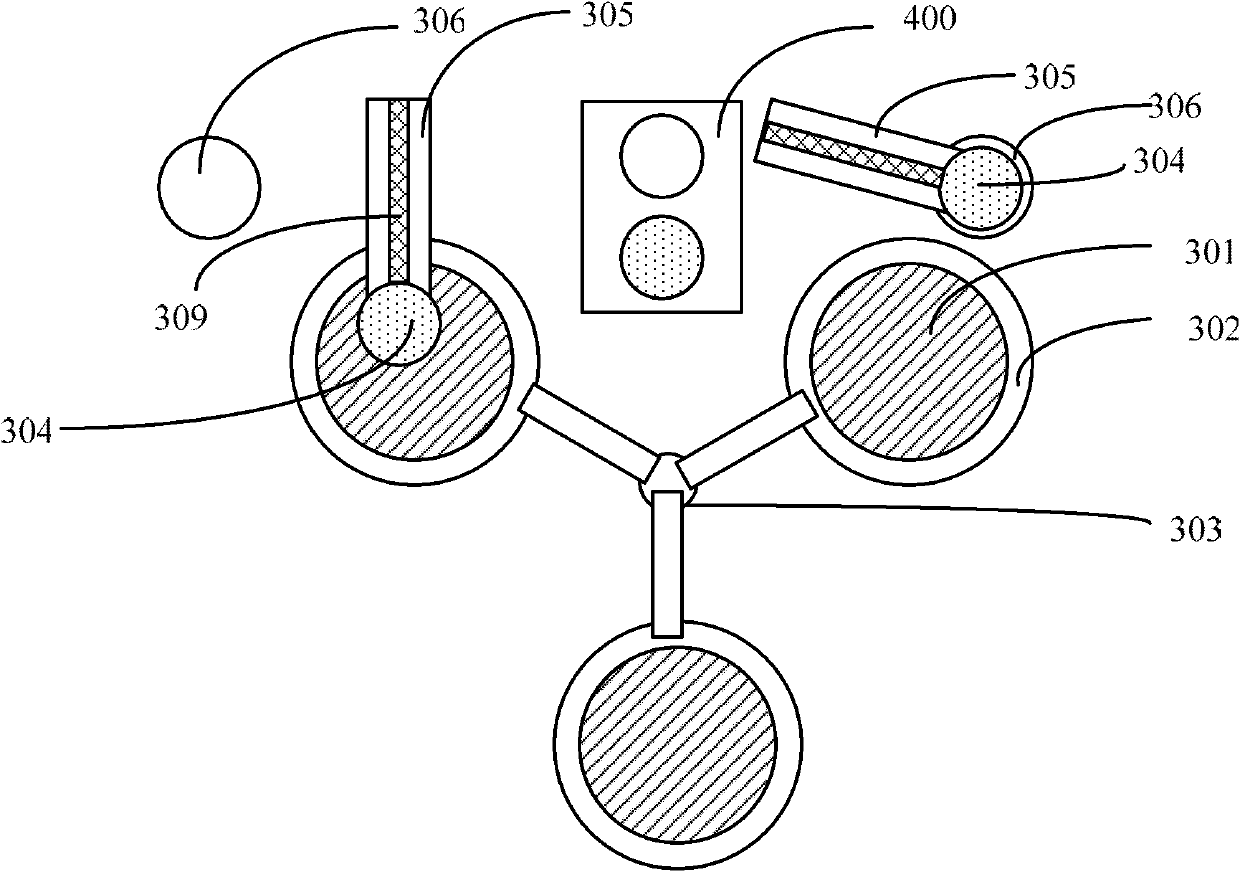

[0036] The chemical mechanical polishing device pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com