Manufacturing method of platinum bar and platinum bar mould-pressing device

A manufacturing method and technology for platinum bars, applied in the manufacture of platinum bars and the field of devices for molding platinum bars, can solve the problems of inability to satisfy customer aesthetics and value preservation, poor processing effect, rough surface of platinum bars, etc., and achieve overall comparison. The effect is obvious, the sand surface is intact and beautiful, and the surface is glossy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

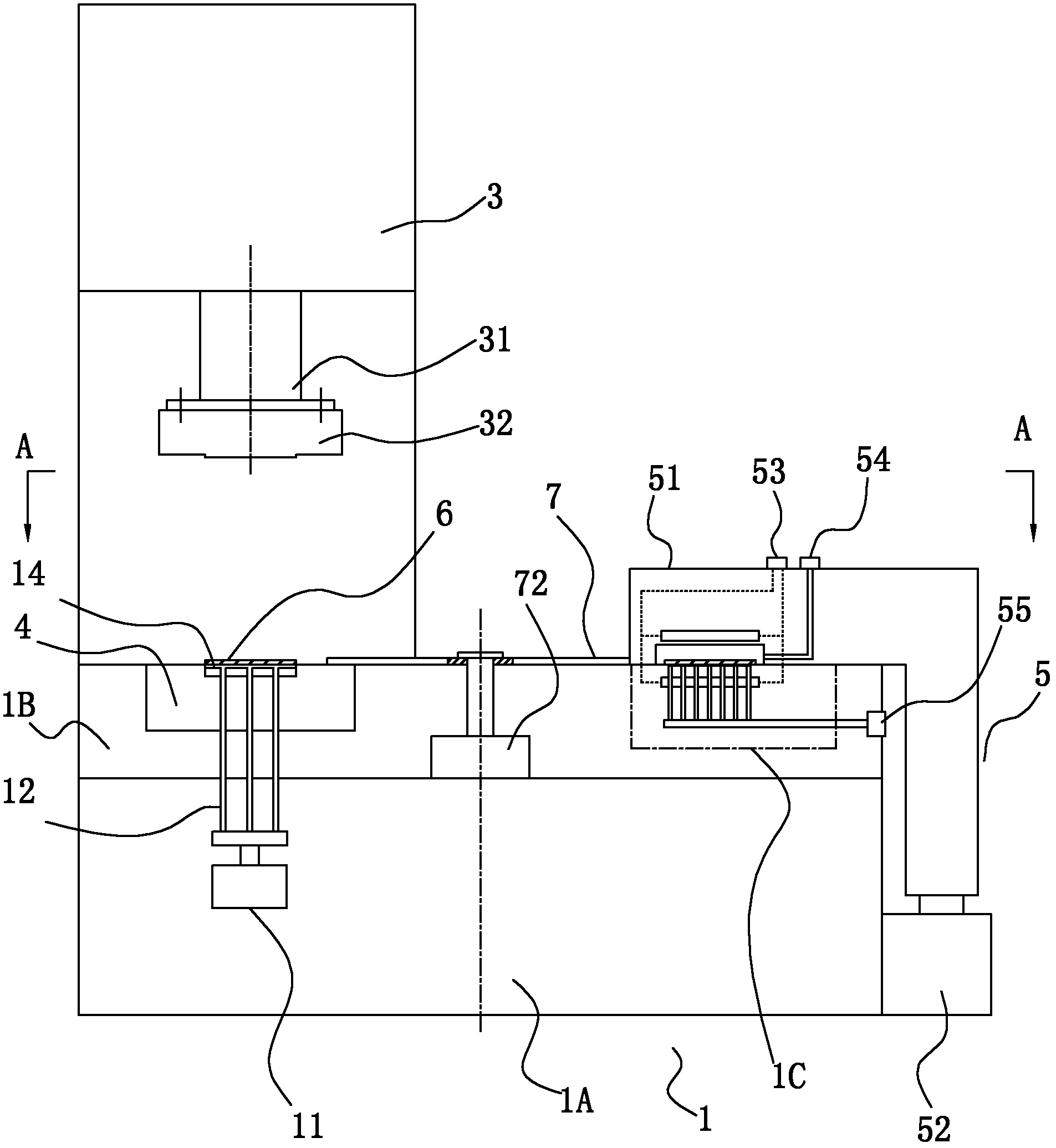

[0035] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

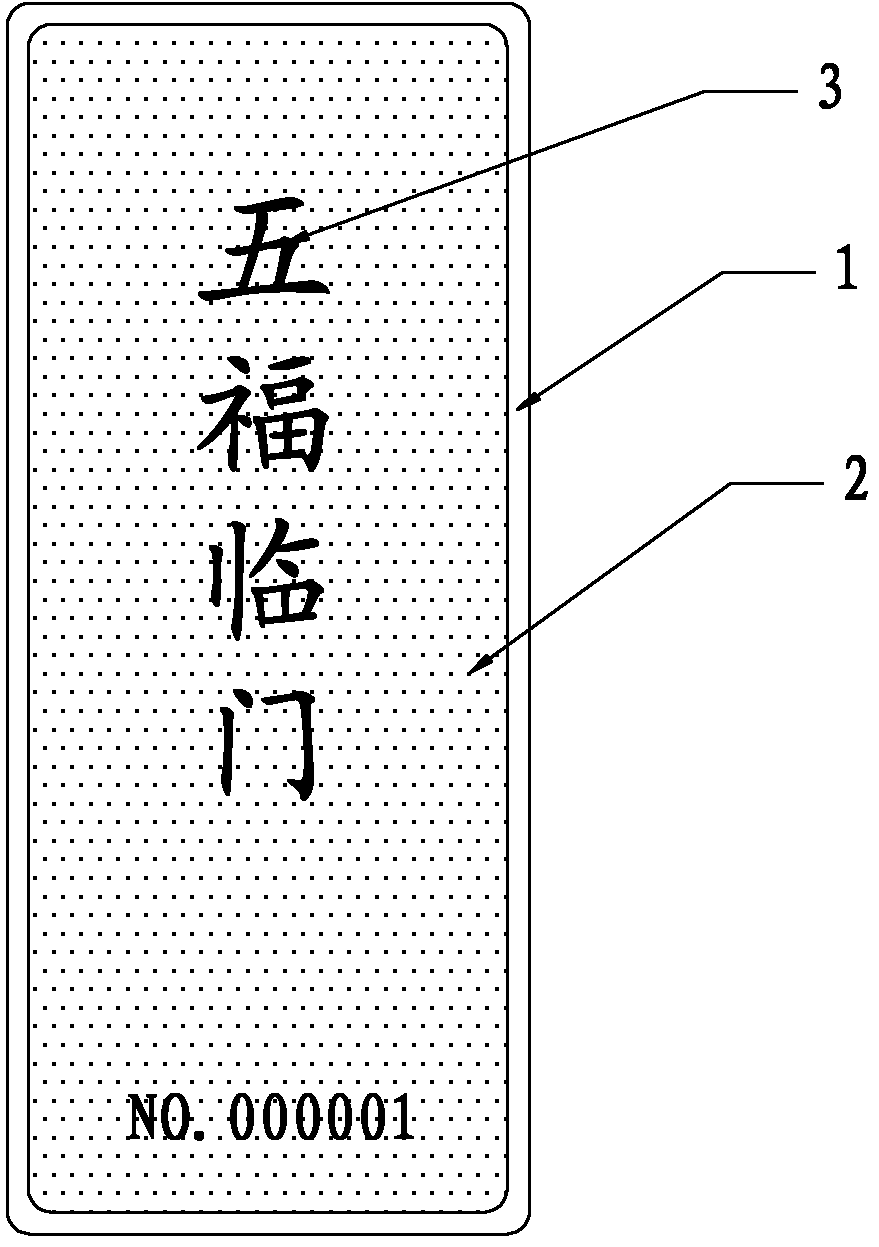

[0036] Such as figure 1 For the embodiment of the manufacturing method of the platinum bar of the present invention, the manufacturing method comprises the following steps:

[0037] (1) Raw material preparation: According to the process requirements and the size and specifications of the platinum bars, the platinum bar blanks are extruded and cut into the required shape and size by using a tablet press and other machines. In this embodiment, the actual weight of the blank 4 corresponding to the 100g Pt999 platinum bar is 103g, the material is Pt999, and the size is 1.15mm*38mm*88mm;

[0038] (2) surface treatment: the blank 4 is immersed in hydrochloric acid with a concentration of 37%, so that the surface scale, oil stains and impu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com