Special multipoint electric resistance welding method

A special resistance and multi-point technology, applied in resistance welding equipment, welding power supply, welding equipment, etc., can solve the problems of welding current and electrode pressure instability, current difference, workpiece resistance difference, etc., to improve production efficiency and ensure production The effect of simple quality and mechanical parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] General equipment requirements:

[0012] All operators operate standing. Therefore, the height of the operating table is 850~900.

[0013] The overall size of the equipment is controlled at 1.5X1.5X2.3M.

[0014] The appearance of the equipment and the operating table should be basically the same.

[0015] The equipment and operating table should be equipped with fluorescent lighting.

[0016] The equipment and operating table should be equipped with documents and recording boards, which are required to be conveniently held and viewed by operators.

[0017] Equipment with mechanical movement must be equipped with an emergency stop button. Safety and error-proofing measures (two-button linkage) must be used.

[0018] The flow of production products and the handling of operators should be facilitated between the equipment and the operating table.

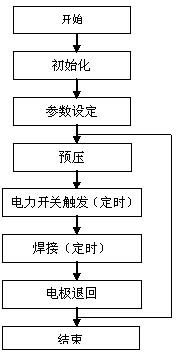

[0019] The projection welding cycle consists of four basic phases:

[0020] Preloading: The electrode is lowered to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com