Mesoporous carbon-loaded gold nano catalyst and application thereof

A gold nanometer and mesoporous carbon technology, which is applied in organic chemistry, amino compound preparation, chemical instruments and methods, etc., can solve the problem of poor oxidation activity of cyclohexene, achieve high specific surface area, no environmental pollution, and simple operation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of Au / SBA-15

[0042] (1) SBA-15-NH 4 + Preparation: 1.0g SBA-15 (prepared according to the literature report of Zhao Dongyuan’s research group, Dongyuan Zhao, Jinyu Sun, Quanzhi Li, Galen D.Stucky.Chem.Mater.2000, 12:275-279.), 2g γ- Add aminopropyltriethoxysilane and 120g ethanol into a 250ml one-necked flask, and heat to reflux for 12h. After cooling, filter, wash with ethanol three times, and dry at room temperature for 12 hours.

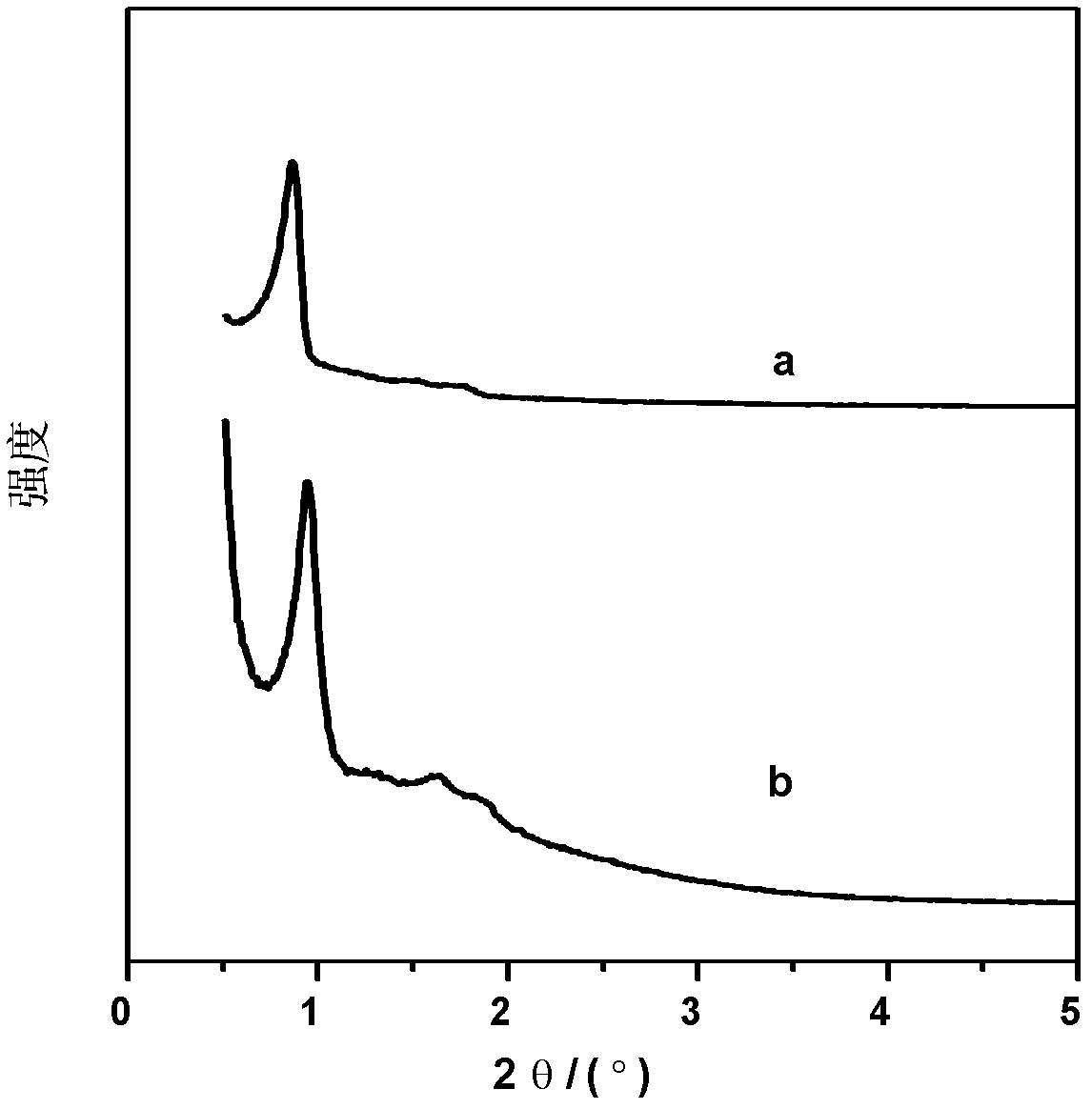

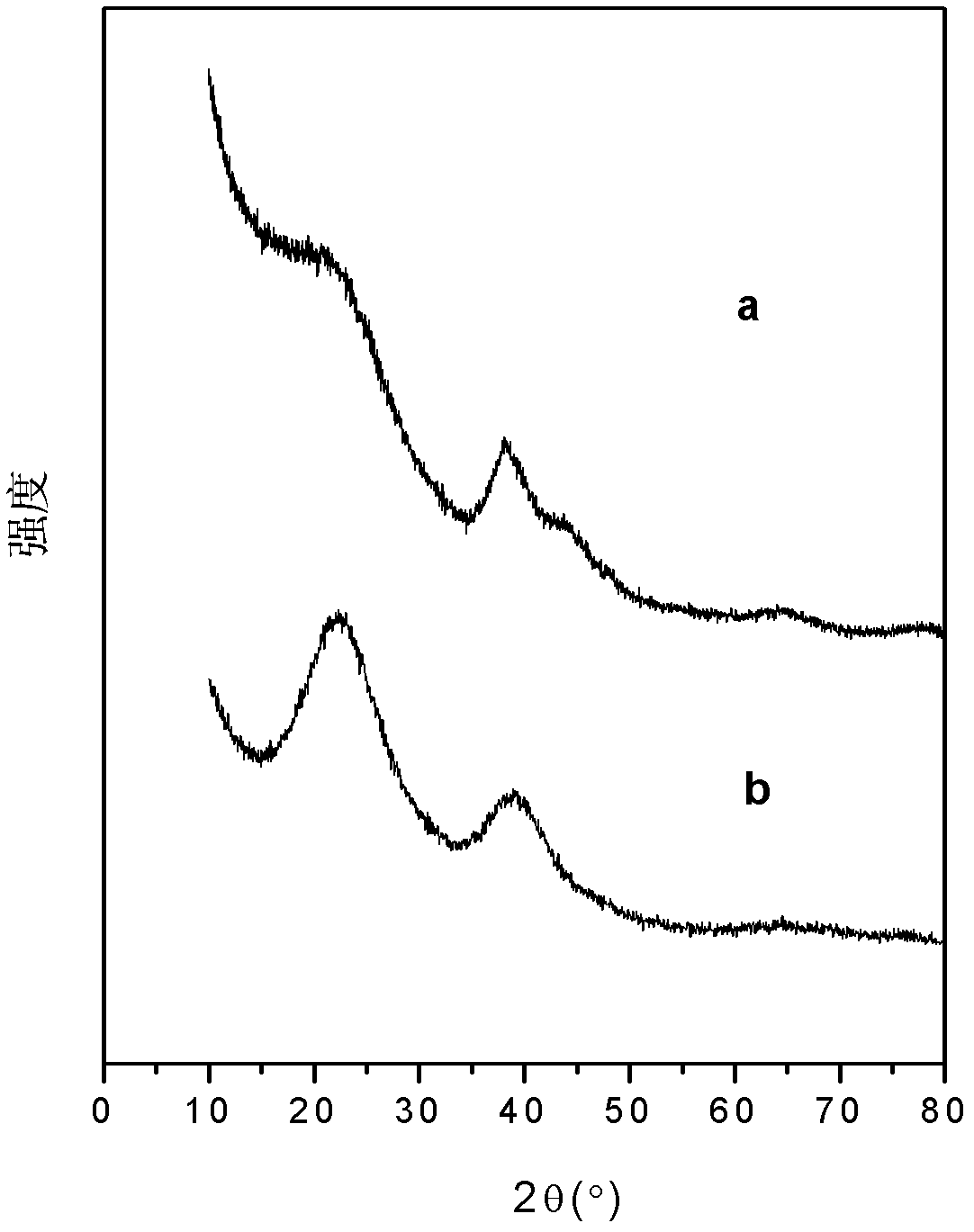

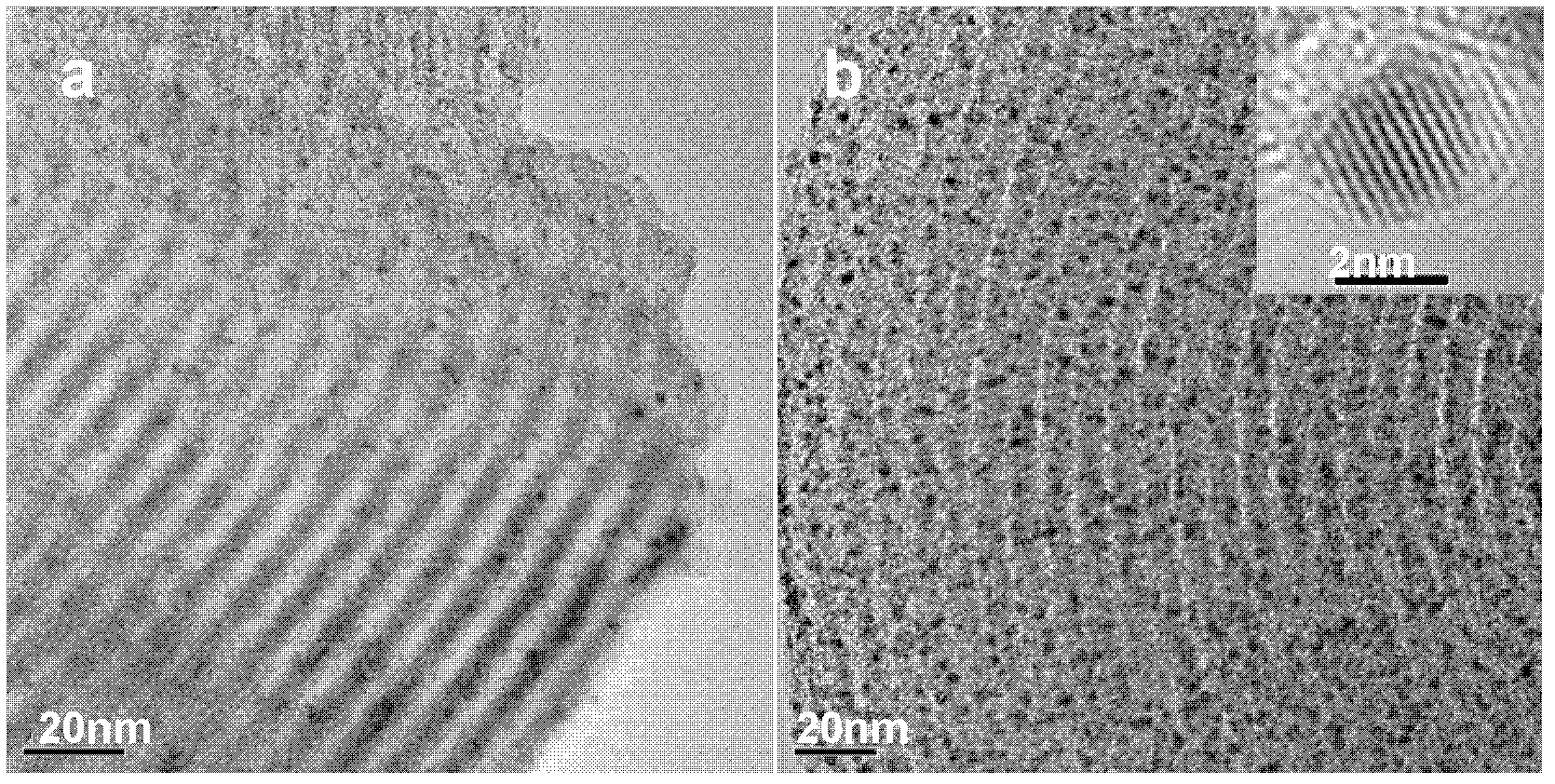

[0043] (2) Loading reaction of Au: take 2.5ml chloroauric acid solution (0.02g / ml), dilute to 20ml, and mix with 1.0gSBA-15-NH 4 + Mix and stir at room temperature for 30 min. Weigh 0.1gKBH 4 , Prepare a solution with 10ml of distilled water, add it dropwise to the above mixture, and continue to stir for 1h. Filter, wash with water and ethanol, and dry at room temperature for 10 h. The obtained sample is characterized by X-ray diffraction, transmission electron microscopy and nitrogen gas adsorption, ...

Embodiment 2

[0044] Embodiment 2: Preparation of Au / mesoporous carbon

[0045] Get the Au / SBA-15 that 1.0g embodiment 1 makes in watch glass, then take by weighing 4.0g 25% phenolic resin (prepared by the method described in literature Joo, S.H.; Choi, S.J.; Oh, I.; Kwak , J.; Liu, Z.; Terasaki, O.; Ryoo, R.Nature 2001, 412 (6843), 169.) solution was added to the same watch glass, after stirring evenly, soaked for 2 hours. After drying in air for 5 hours, transfer into quartz boats. Put the quartz boat into a quartz tube furnace, and program the temperature rise carbonization under the protection of nitrogen. The setting of the temperature program is: increase the temperature to 350°C at a rate of 1°C / min, maintain at 350°C for 2 hours, continue to increase the temperature to 700°C at a rate of 1°C / min, and maintain for 2 hours. Weigh 50g of ethanol, 2g of NaOH, and 40g of water to prepare lye. Transfer the carbonized sample and lye into a polytetrafluoroethylene tube, and keep the reac...

Embodiment 3

[0046] Example 3: Activity Evaluation of Au / Mesoporous Carbon Catalyzed O-Chloronitrobenzene Hydrogenation

[0047] In a 100ml stainless steel autoclave, add 0.1g of Au / mesoporous carbon prepared in Example 2, 5.0g of o-chloronitrobenzene, and 50ml of ethanol. Seal the reaction kettle, replace the air in the kettle with nitrogen, raise the temperature to 130°C, add hydrogen to 3Mpa, start stirring (1000r / min), react at constant temperature for 7 hours, stop the reaction and cool to room temperature. The reaction solution was taken out, the catalyst was removed by filtration, and the filtrate was analyzed by gas chromatography. The conversion rate of o-chloronitrobenzene was 94.3%, the selectivity of o-chloroaniline was 98.3%, and the dechlorination was only 0.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com