Clamp ring, cable screw connection and method for assembling a cable screw connection

A technology for cable glands and clamping rings, which is applied to cable terminals, clamping/spring connections, parts of connection devices, etc., and can solve problems such as uncertain loosening torque, loosening of cable glands, laborious inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

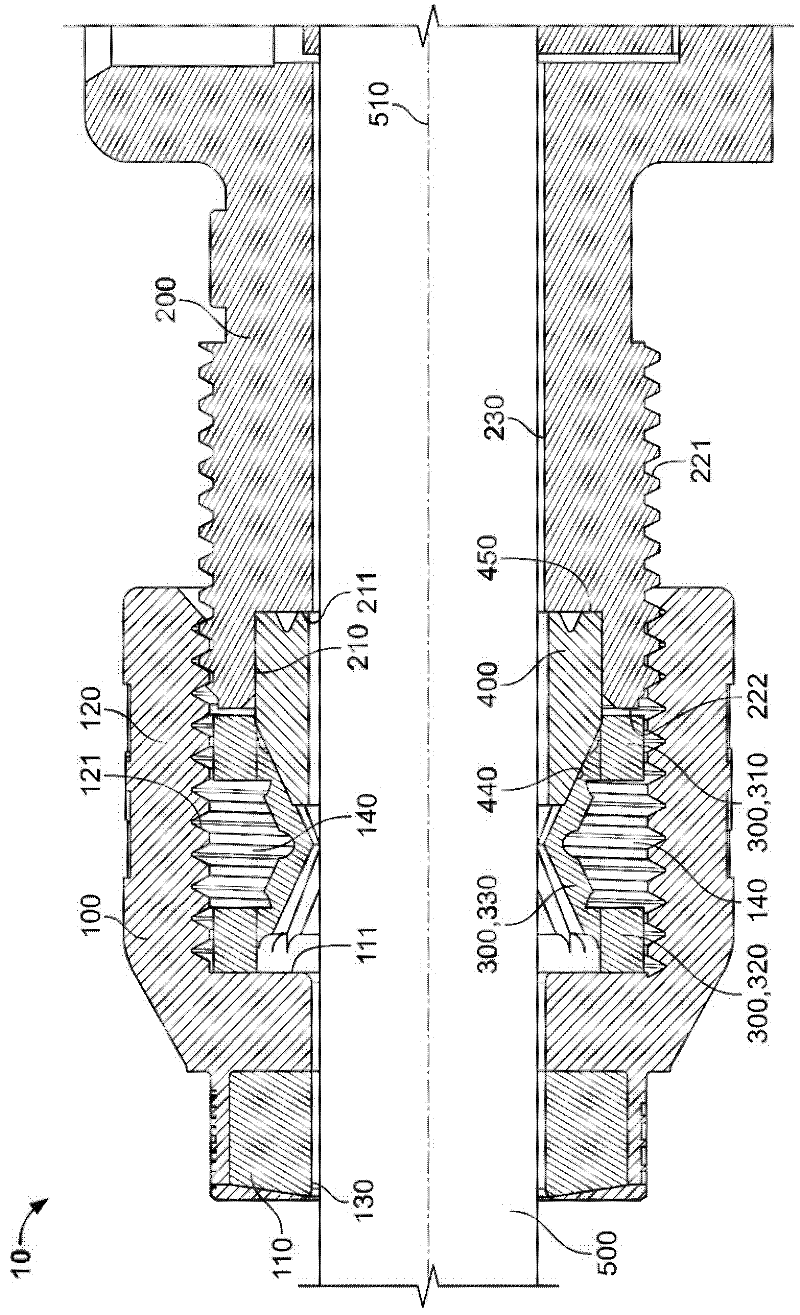

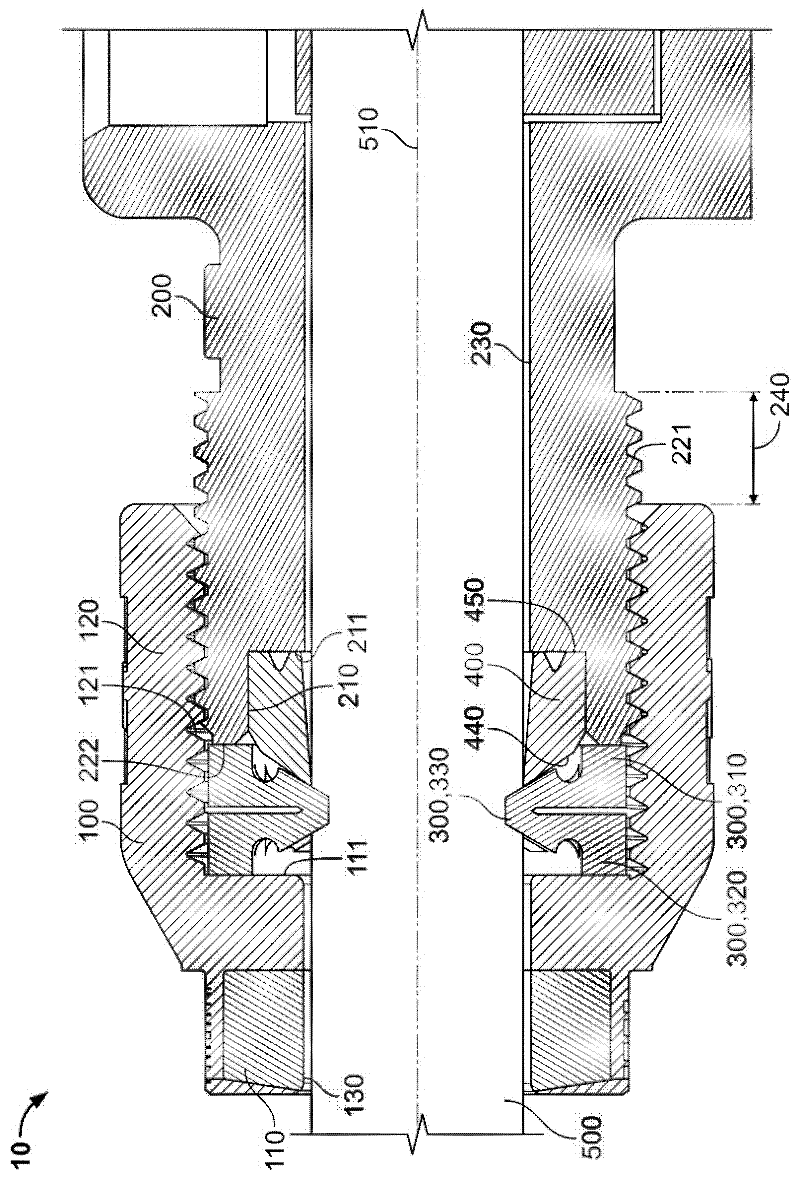

[0022] figure 1 A section through the cable gland 10 partially screwed onto the counterpart part 200 is shown somewhat schematically. The counter part 200 may be, for example, a plug, a socket, a cable bushing in a housing or a different counter part. The cable gland 10 serves to fix the cable 500 fed to the counterpart part 200 to the counterpart part 200 to prevent any undue loosening of the cable 500 from the counterpart part 200 . The cable gland 10 also serves to seal the counter part 200 .

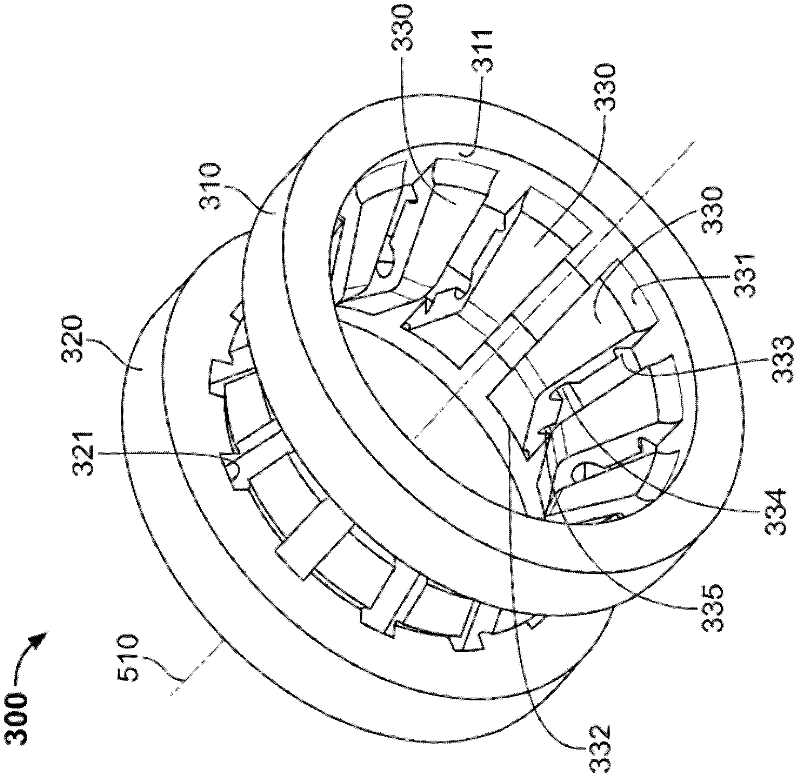

[0023] The cable gland 10 includes a nut 100 , a clamping ring 300 and a seal 400 . The nut 100, the clamping ring 300, the seal 400 and the counter part 200 are each substantially rotationally symmetrical, and in figure 1 They are tangent to a plane extending through a common longitudinal axis 510 which forms the axis of symmetry.

[0024] The nut 100 has a guide portion 110 and a threaded portion 120 . The first feed-through hole 130 extends along the longitudinal axis 510 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com