Silicon PIN neutron dose detector and manufacture method thereof

A neutron dose and detector technology, which is applied in the field of silicon PIN neutron dose detectors and its preparation, can solve the problems of increased production cost and process difficulty, silicon PIN detector defects, etc., and achieve cost reduction and process complexity, Reduced requirements, effects of uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

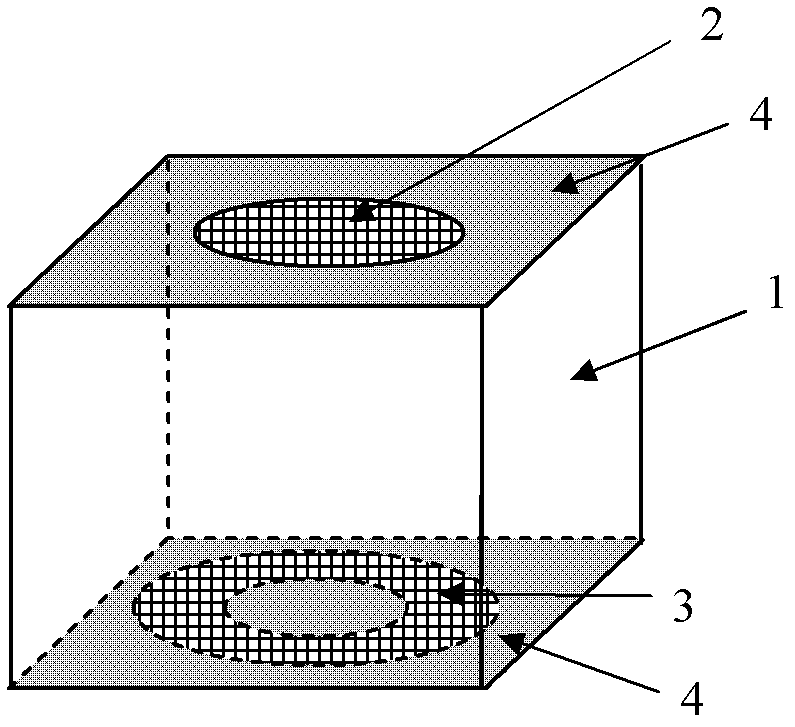

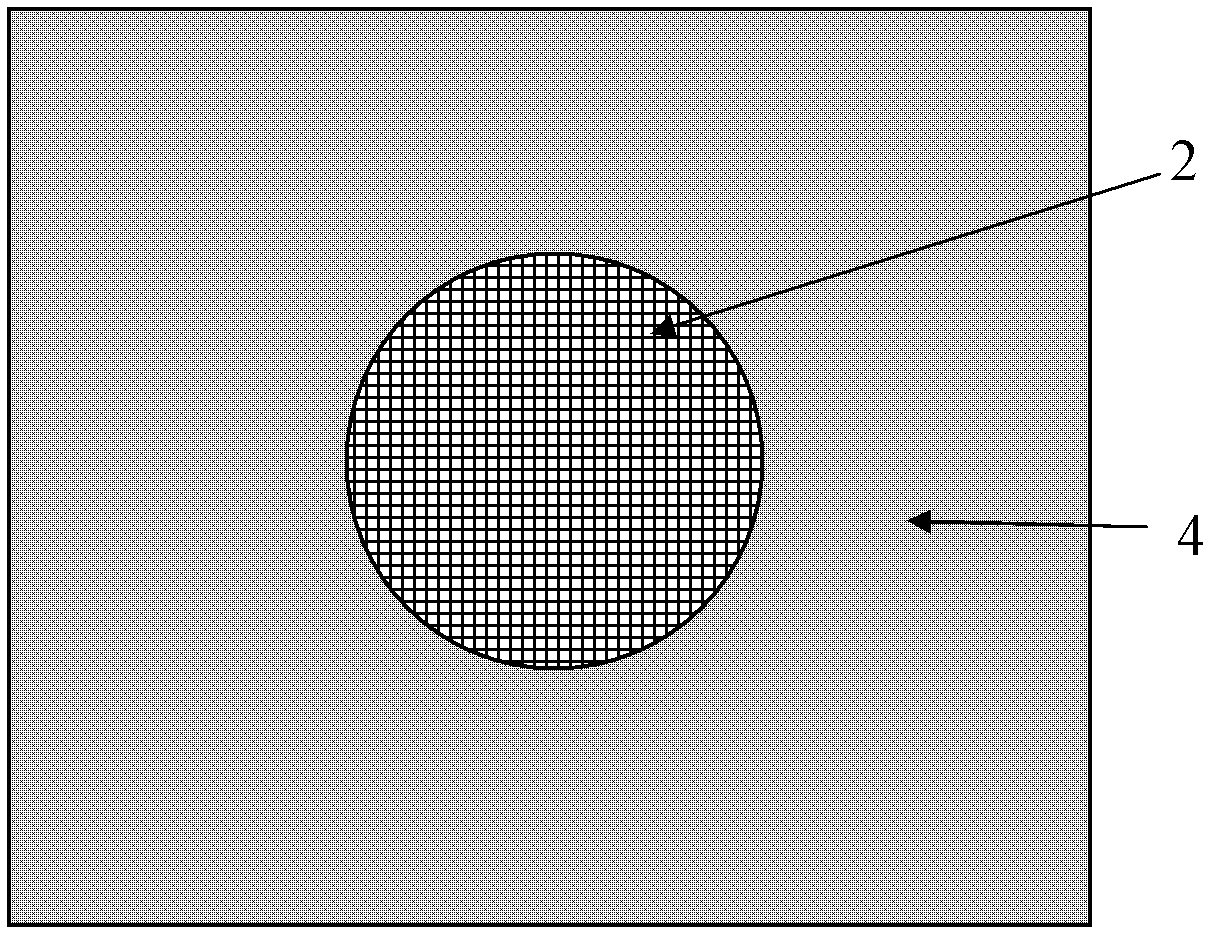

[0035] The following examples are intended to be prepared by a specific manufacturing method figure 2 The silicon PIN neutron dose detector shown, the silicon PIN neutron dose detector includes a double-sided polished high-resistance silicon wafer 1 as a substrate, and has a circular P-type active layer on the front and back sides of the silicon wafer 1 Area 2 and N-type active area 3, silicon dioxide layer 4 is on the silicon surface outside the active area.

[0036] Concrete manufacturing method comprises the following steps:

[0037] 1. If Pic 4-1 As shown, a double-sided polished high-resistance silicon wafer 1 as a substrate is oxidized at a high temperature of 1000 ° C, and a thickness of 8000 is formed on the upper and lower surfaces of the silicon wafer. the sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com