Low-power Si-Al alloy material with magnetic permeability μ=26 and its preparation method

A technology of sendust and magnetic permeability, which is applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of no large-scale manufacturers and low production volume, and improve the DC bias configuration capacity, ease of use of equipment, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get 1000g sendust powder, wherein the weight content of Si is 9%, the weight content of Al is 6%, the Ni of 1% by weight and the Cr of 1% by weight, and the balance is Fe, the prepared sendust When the powder is roasted until the temperature reaches 100°C, add 2.5% phosphoric acid diluent for surface treatment, and then continue roasting until dry; then press the iron-silicon-aluminum alloy soft magnetic powder: the pressure is 20 tons / cm 2 ; and through heat treatment, hydrogen or nitrogen gas is passed into the heat treatment furnace, the temperature is controlled at 750±3°C, and the heat treatment time is 150 minutes; finally, epoxy resin paint is used to coat the surface of the powder core. Obtained 2 sendust products with specifications of Φ26.9 / Φ14.7×11.2 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm).

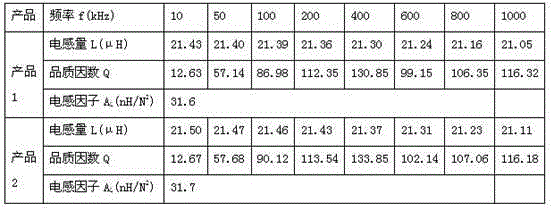

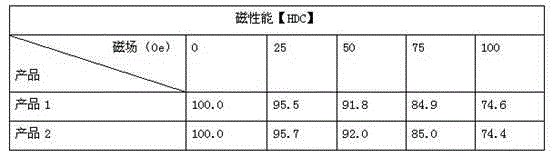

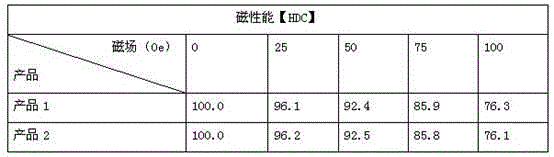

[0025] (1) f﹑L﹑Q test

[0026] The copper wire adopts Φ0.5mm, and the number of turns of the coil is 26 turns, a...

Embodiment 2

[0042] Get 1000g sendust powder, wherein the weight content of Si is 9.5%, the weight content of Al is 5.6%, the Ni of 0.8% by weight and the Cr of 0.5% by weight, the balance is Fe, according to the process step of embodiment 1 The sendust powder is pressed into two sendust products with specifications of Φ26.9 / Φ14.7×11.2 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm). Other conditions remain unchanged.

[0043] (1) f﹑L﹑Q test

[0044] The copper wire adopts Φ0.5mm, and the number of turns of the coil is 26 turns, and its magnetic performance parameters are shown in Table 5.

[0045] table 5

[0046]

[0047] (2) Power loss test

[0048] The copper wire is Φ0.5mm, and the number of turns of the coil is 26 turns, and its magnetic performance parameters are shown in Table 6.

[0049] Table 6

[0050] product Frequency f(kHz) Magnetic flux density B pk (Gauss) Power loss Product 1 50 100 4.76 ...

Embodiment 3

[0060]Get 1000g sendust powder, wherein the weight content of Si is 10%, the weight content of Al is 6%, the Ni of 0.5% by weight and the Cr of 0.5% by weight, the balance is Fe, according to the process step of embodiment 1 The sendust powder is pressed into two sendust products with specifications of Φ26.9 / Φ14.7×11.2 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm). Other conditions remain unchanged.

[0061] (1) f﹑L﹑Q test

[0062] The copper wire is Φ0.5mm, and the number of turns of the coil is 26 turns, and its magnetic performance parameters are shown in Table 9.

[0063] Table 9

[0064]

[0065] (2) Power loss test

[0066] The copper wire is Φ0.5mm, and the number of turns of the coil is 26 turns, and its magnetic performance parameters are shown in Table 10.

[0067] Table 10

[0068] product Frequency f(kHz) Magnetic flux density B pk (Gauss) Power loss Product 1 50 100 5.58 Produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com