Capacitive touch panel

A technology of touch panel and electrostatic capacitance, which is applied in the direction of electrical digital data processing, instrumentation, and input/output process of data processing, etc. It can solve the problems of difficult detection and long detection time, and achieve the reduction of detection error and increase of parasitic capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

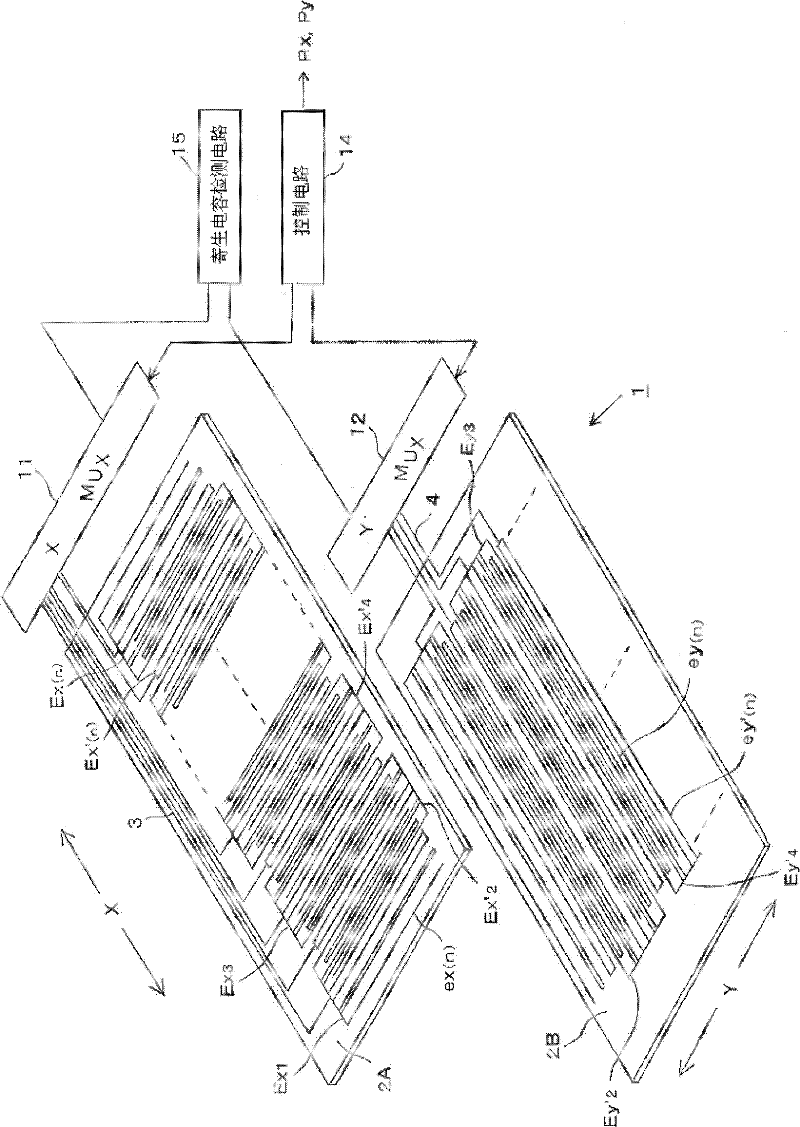

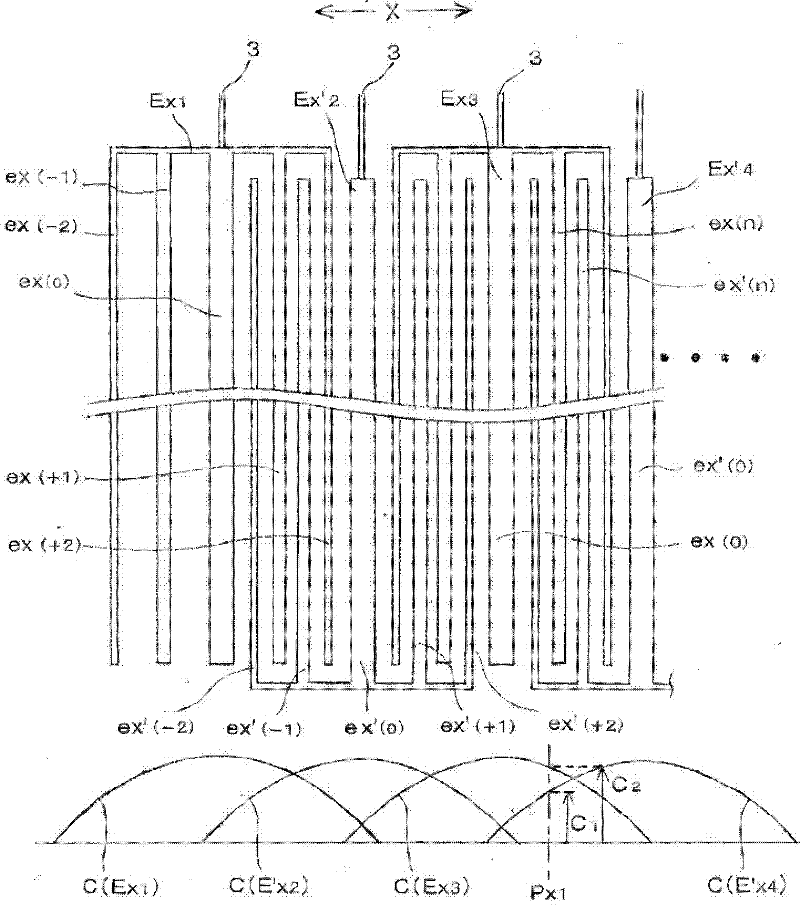

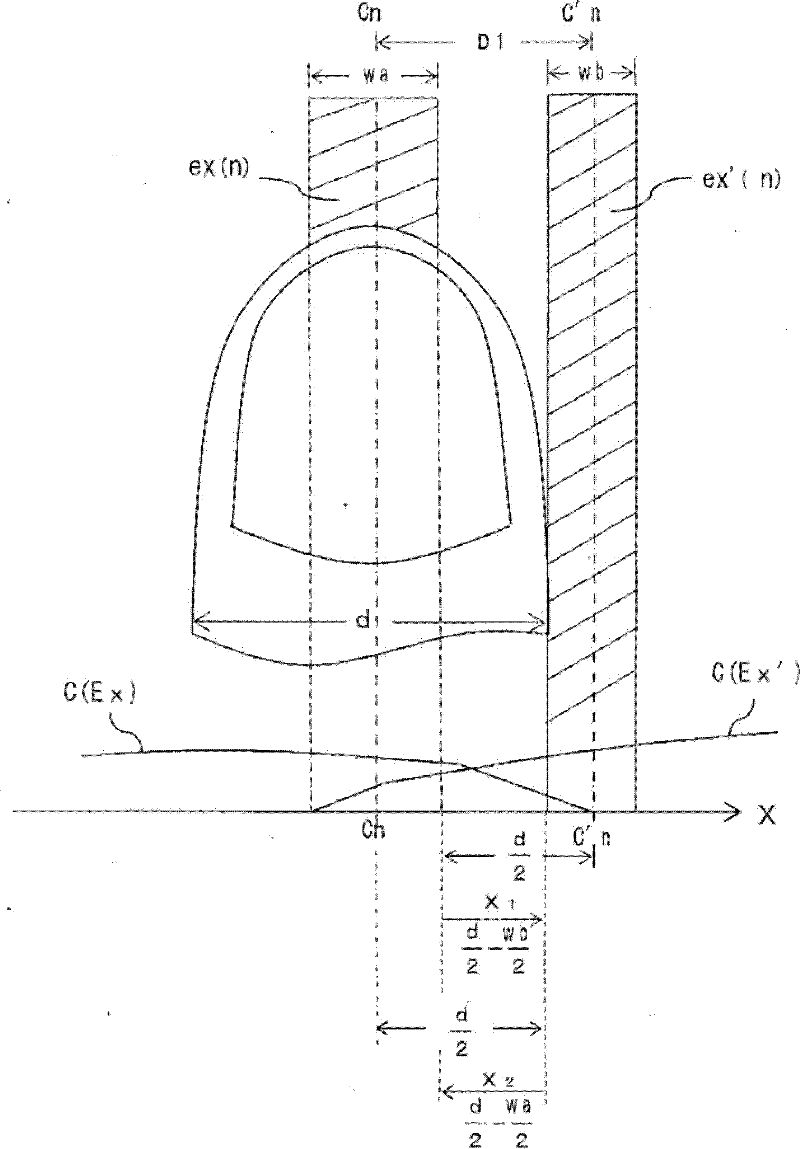

[0066] Below, refer to Figure 1 to Figure 5 The capacitive touch panel 1 according to one embodiment of the present invention will be described. like figure 1 As shown, the electrostatic capacitive touch panel 1 detects the input operation positions Px, Py when the finger 10 used as the input operation body approaches in the mutually orthogonal XY direction, and 29 wires are arranged at a predetermined pitch along the X direction of the surface. An insulating substrate 2A of X detection electrodes Ex, Ex' and an insulating substrate 2B on which 16 Y detection electrodes Ey, Ey' are wired at a predetermined pitch along the Y direction of the surface are laminated.

[0067] As long as the two insulating substrates 2A, 2B are materials that can form conductive detection electrodes Ex, Ex', Ey, Ey' on their surfaces, they can be made of polyethylene terephthalate (PET) or polyimide. It is made of various materials such as polyimide tough plastic film, but a transparent tempere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com