Immersion lithography method and system

An immersion lithography and processing system technology, applied in the field of immersion lithography and its processing system, can solve problems such as generation problems, uneven heat absorption and evaporation, photoresist patterning, and adverse effects of feature sizes, etc., to achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

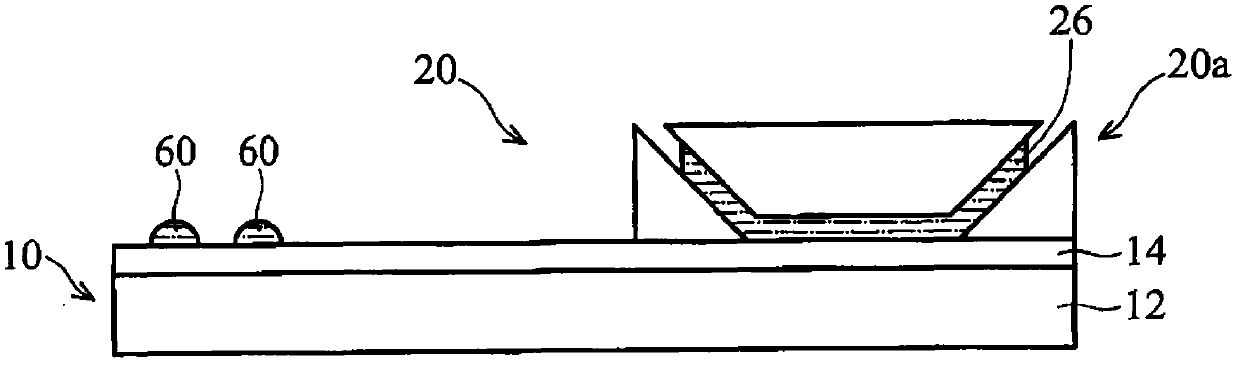

[0042] see figure 1 The semiconductor wafer 10 includes a base 12 and a patterned layer 14 , the base 12 is a structure of one or more layers, including polysilicon, metal and / or dielectric, which will be patterned. The patterned layer 14 can be a photoresist layer, which can be patterned by an exposure process, and the wafer 10 is placed in an immersion photolithography system 20 .

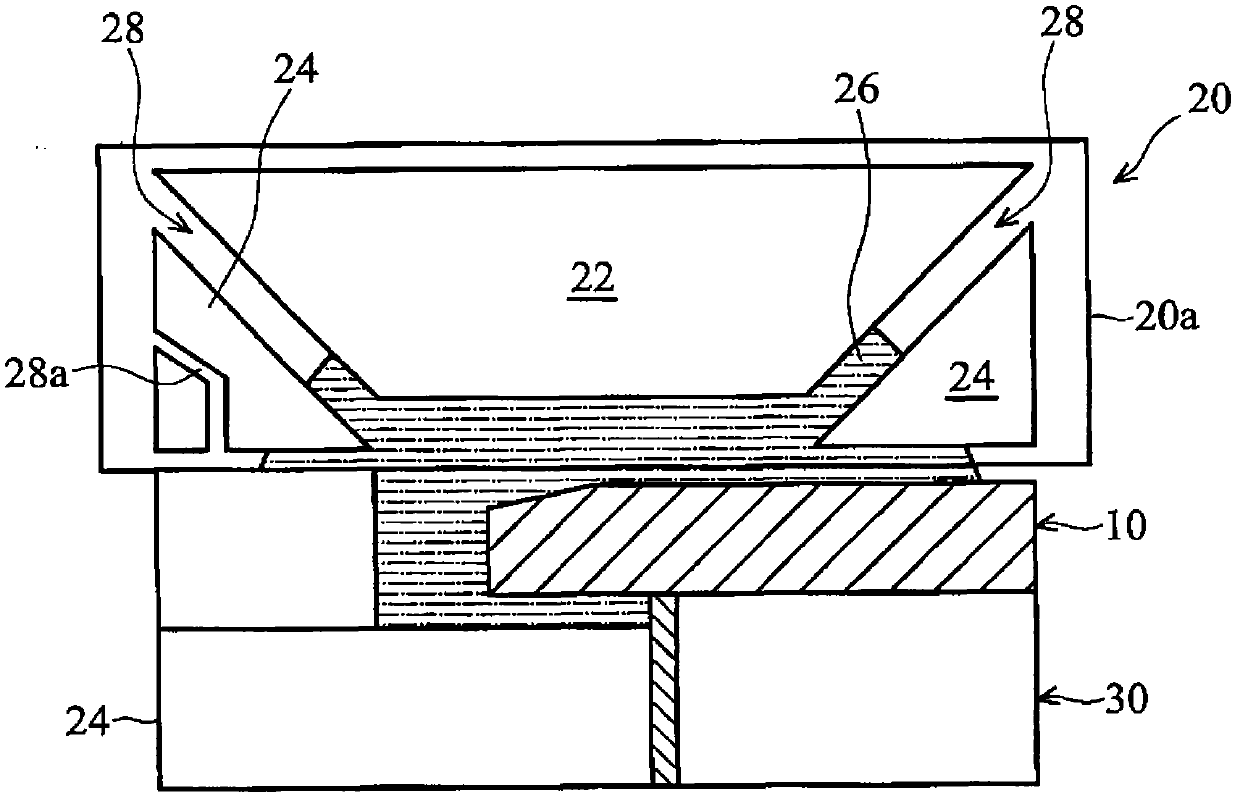

[0043] refer to figure 2 , which is an immersion lithography system 20 comprising a lens system 22; a structure 24 carrying a liquid 26 (eg, deionized water); a plurality of openings 28 through which liquid can be added or removed; and a chuck 30 for holding a wafer 10, and make the wafer move relative to the lens system 22. The liquid-carrying structure 24 and the lens system 22 form the wetting head 20a. The wetting head 20a can use some openings (such as openings 28a) for air drying (airpurge) to allow air to dry the wafers, and other openings for removing cleaning liquid. However, a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com