Coil of optical fiber current sensor and optical fiber current sensor

A sensor coil, optical fiber current technology, applied in the direction of measuring current/voltage, voltage/current isolation, instruments, etc., can solve the problems of crosstalk between two orthogonal modes, affecting measurement accuracy, weakening stability, etc., and achieve strong anti-electromagnetic interference ability , Improve the stability of the zero bias and the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

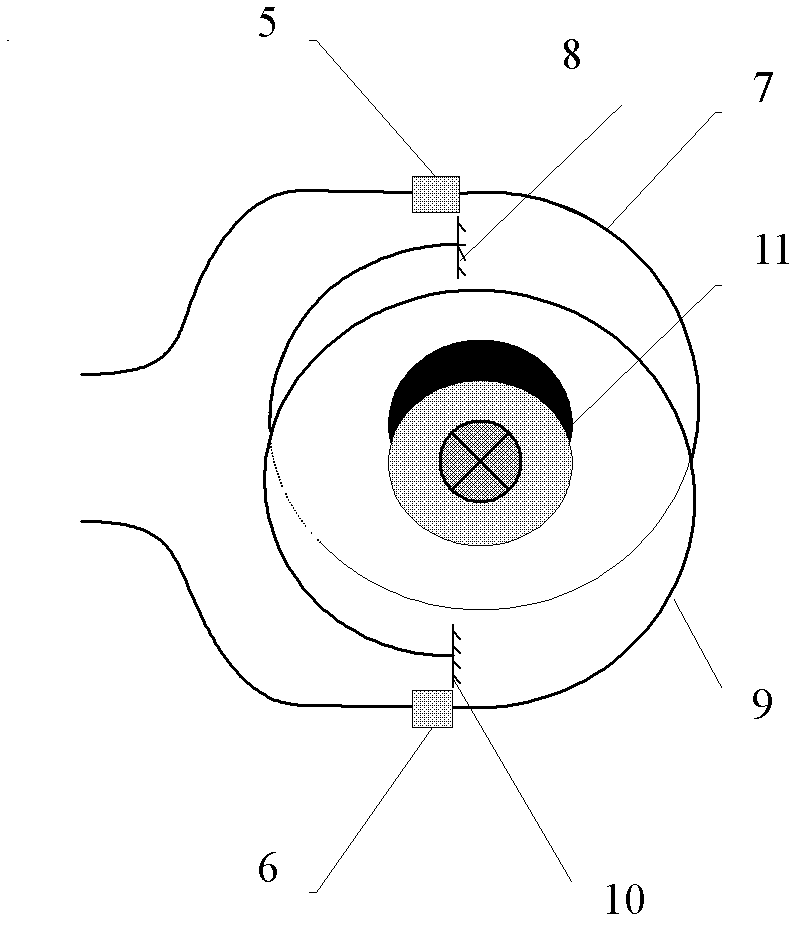

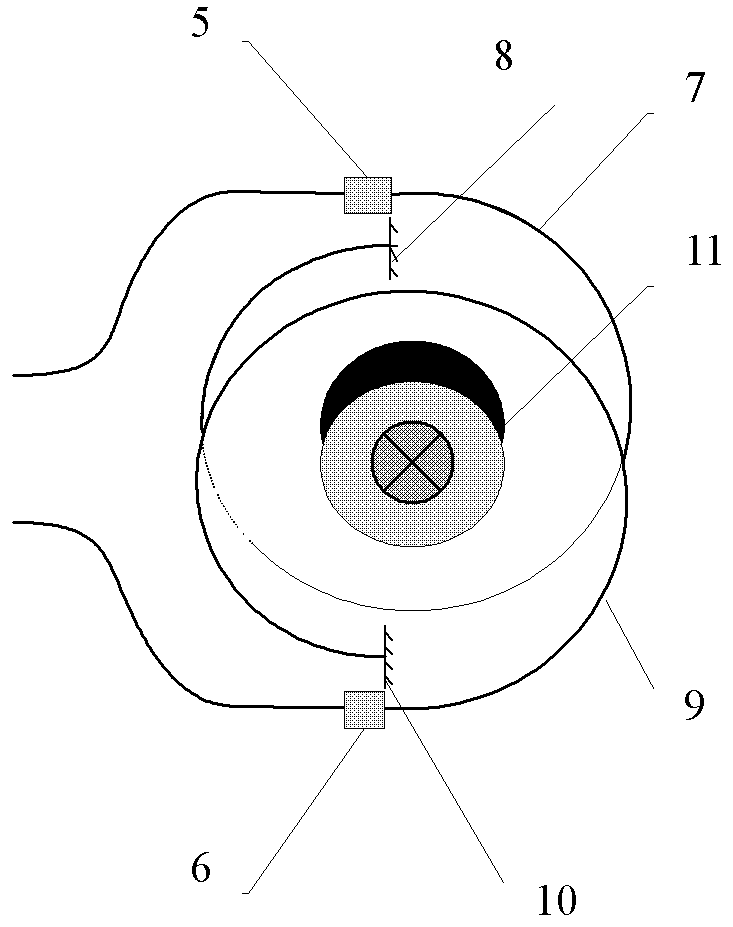

[0028] see figure 1 , the present invention provides a fiber optic current sensor coil, including a first current sensing optical path wound on the current to be measured, the fiber optic current sensor also includes a coil wound on the current to be measured and wound with the first current sensing optical path Control the second current sensing optical path in the opposite direction.

[0029] The second current sensing optical path includes a second quarter-wave plate 6, a second sensing fiber 9 and a second mirror 10; the second quarter-wave plate 6 is connected to the second sensing fiber 9 through the second Reflector 10; the second sensing fiber 9 is wound on the current 11 to be measured. The first current sensing optical path comprises a first quarter-wave plate 5, a first sensing fiber 7 and a first reflector 8; the first quarter-wave plate 5 is connected to the first Mirror 8; the first sensing fiber 7 is wound on the current 11 to be measured. The winding directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com