Novel process for pyrolysis of solid wastes

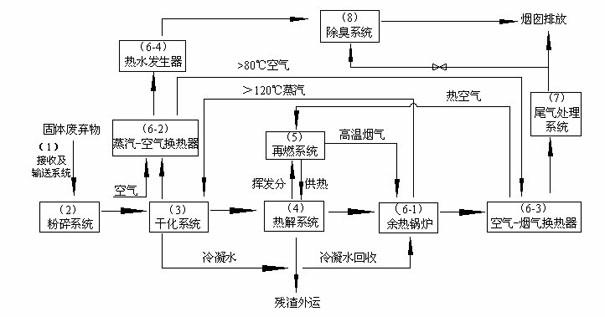

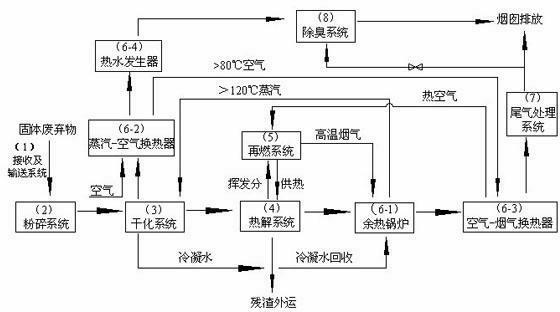

A new process, pyrolysis technology, applied in pyrolysis treatment of sludge, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of imperfect process, low treatment efficiency, secondary pollution, etc., and achieve saving Energy, simple processing steps, and the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, sludge with a moisture content of 67% after deep dehydration:

[0023] Because the sludge form is relatively uniform, it does not need to be pulverized in the early stage. 10 tons of sewage sludge with a water content of 67% is dried through the material receiving and conveying system (1) into the sludge drying system (3) (hollow rotary disc, hollow paddle dryer), and the water content of the sludge The rate is reduced to 25-30%, and the weight is about 4.4-4.71 tons. The dried sludge with 25-30% water content enters the sludge pyrolysis system (4) (the main equipment is a pyrolysis furnace) for pyrolysis treatment, and about 1.772 tons of organic carbon products (higher ash content) are obtained. The particles can be used In the construction of urban greening trees, the oil and gas (volatile matter) produced by pyrolysis are burned through the reburning system (5) to supply the energy required by the pyrolysis system (4). The high-temperature flue gas o...

Embodiment 2

[0027] Embodiment 2: sludge with a moisture content of 80%

[0028] 10 tons of sewage sludge with a water content of 80% will be dried through the material receiving and conveying system (1) into the sludge drying system (3) (partition-wall sludge dryers can be implemented), and the water content of the sludge will be reduced The rate is reduced to 25-30%, and the weight is about 2.67-2.85 tons. The dried sludge with 25-30% water content enters the sludge pyrolysis system (4) (the main equipment is the pyrolysis furnace) for pyrolysis treatment, and at the same time starts the crushing system (2) to crush 800kg of straw, and the crushing uses a separate feeder The material device is sent to the pyrolysis system (4), and the pyrolysis system (4) contains about 1.324 tons of organic carbon products. This organic carbon product can be used for urban greening and forestry construction. The system (5) burns for the energy required by the pyrolysis system (4). The high-temperature...

Embodiment 3

[0030] Embodiment 3: the technology of the pyrolysis of food waste

[0031] Food waste has the characteristics of high water content, high organic content, high oil content and high salt content. Its main components are starch, dietary fiber, animal fat, rich in protein, vitamins, edible oil and cellulose, and nutritious. Rich, with high recycling value, very suitable for resource reuse.

[0032] The high water content of food waste is generally above 60%. The food waste enters the crushing system (2) through the receiving and conveying system (1), and is crushed and sieved until the particle size is less than 2mm, and sent to the drying system (3) for drying and removal Moisture to reduce the moisture content to 25-30%, and then enter the pyrolysis system (4) through the feeding device. The pyrolysis temperature of food waste is determined to be 600°C. If the calorific value is low, additional biomass energy needs to be added to ensure normal operation of the system. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com