New process for treating solid waste by taking thermal conditioning as secondary and pyrolysis as primary

A technology for solid waste and thermal conditioning, which is applied in the pyrolysis treatment of sludge, the removal of solid waste, and the vaporization of by-products. The effect of energy saving, simple treatment process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below by specific embodiment:

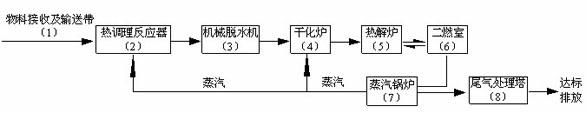

[0016] like figure 1 As shown, taking sludge as an example, the process flow of sludge pyrolysis in this system is introduced:

[0017] Sewage sludge with a moisture content of about 80% enters the thermal conditioning reactor 2 through the material receiving and conveying belt 1 for high temperature and high pressure reaction. The reaction time is controlled at about 1 hour, the reaction temperature is controlled at 100 ° C ~ 350 ° C, and the reaction pressure is 0.1 Between MPa and 15.0MPa, after passing through the reactor, the sludge is dehydrated by the mechanical dehydrator 3, and the moisture content of the sludge is reduced to 45% to 50%, and then enters the drying furnace 4 for drying treatment, and the moisture content is reduced to The sludge with a moisture content of less than 25% enters the pyrolysis furnace 5 to be thermally decomposed, and the temperature in the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com