Multiple gas-circuit gas pressure on-line quantitative distribution system

A gas pressure and quantitative distribution technology, which is applied in gas/liquid distribution and storage, pipeline systems, signal transmission systems, etc., can solve problems affecting system work, high system cost, troublesome maintenance, etc., and achieve convenient data detection and transmission , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

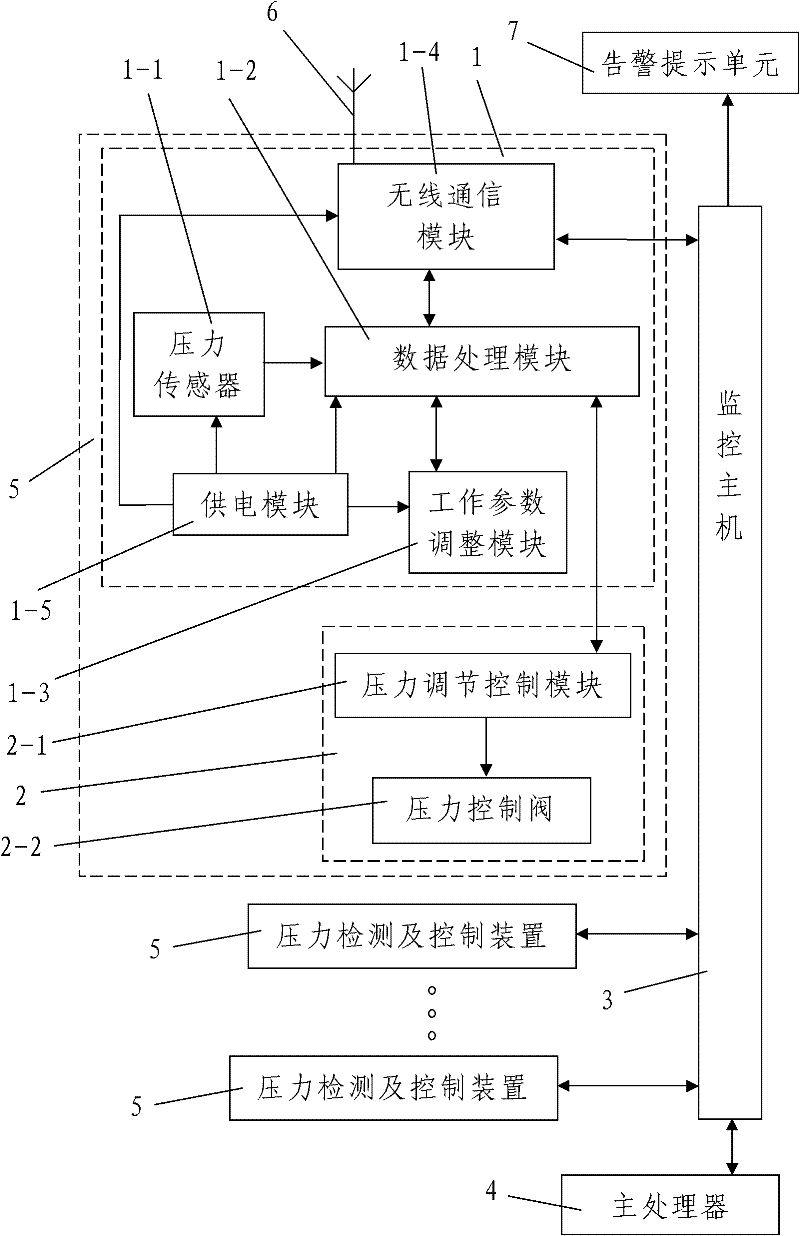

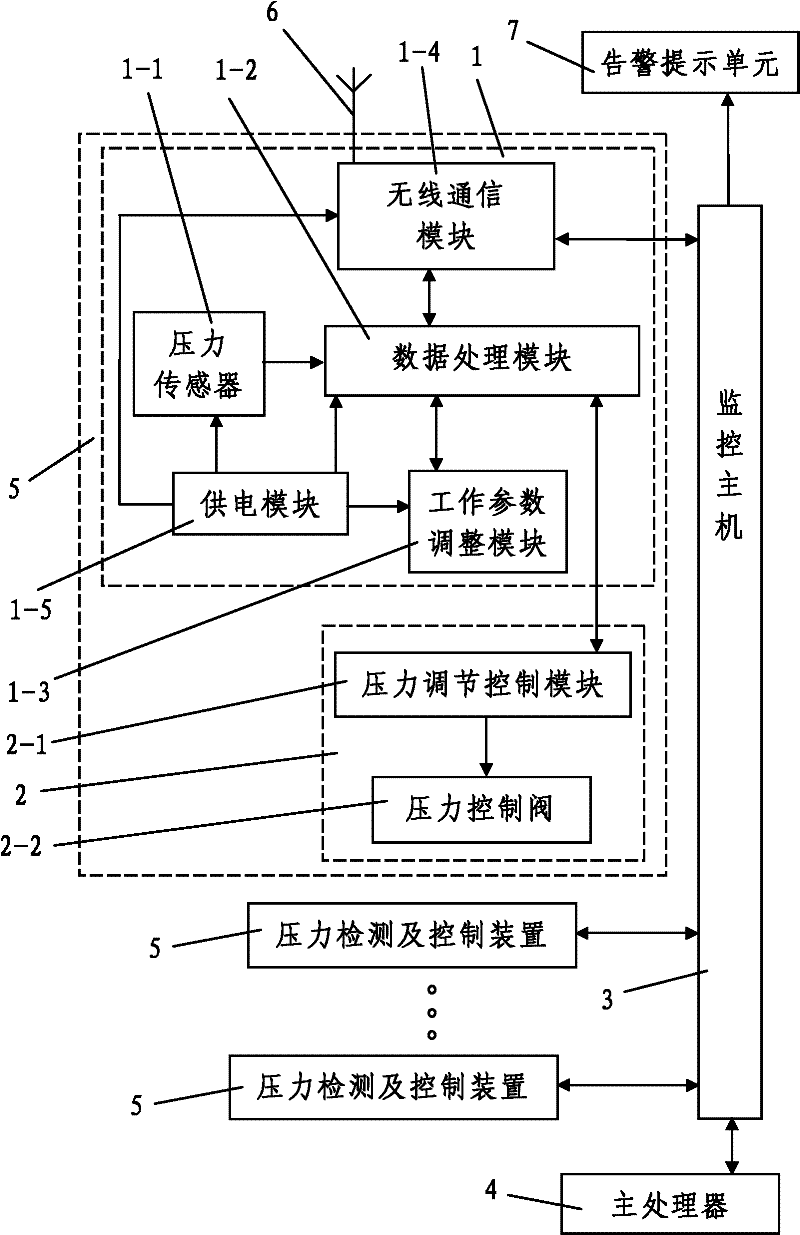

[0024] Such as figure 1 As shown, the present invention includes a plurality of pressure sensor nodes 1 respectively installed in a plurality of controlled gas circuits, a plurality of pressure sensor nodes 1 respectively installed in a plurality of controlled gas circuits and synchronously adjusting the gas pressure in each gas circuit The control unit 2, analyzes and processes the air pressure control curves of a plurality of controlled air circuits and correspondingly calculates the air pressure distribution ratio relationship between the plurality of controlled air circuits at any time, and the main processor 4 is arranged in the remote data monitoring center and According to the air pressure distribution proportional relationship calculated by the main processor 4, the monitoring host 3 that controls the multiple pressure control units 2, the multiple pressure sensor nodes 1 and the multiple pressure control units 2 are all along multiple The gas flow in the controlled ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com