Post-treatment fixation process for fabric dyeing

A fabric dyeing and process technology, applied in the field of fabric dyeing, can solve the problems that plague dyeing factories, fail to reach customers, and can only reach about level 2, etc., to achieve improved dyeing fastness, wet rubbing fastness, and soaping fastness The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

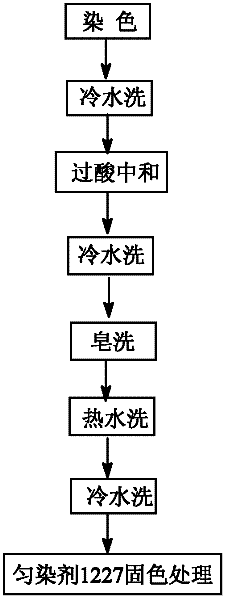

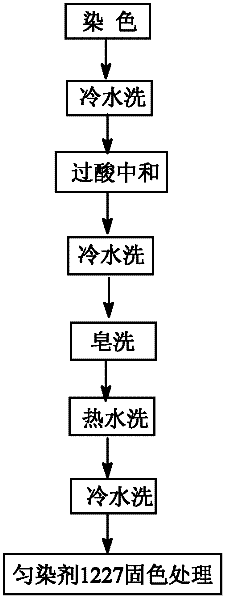

Image

Examples

Embodiment 1

[0010] Example 1: 32s 2*2 cotton spandex lake blue rib fabric

[0011] The dosage of reactive turquoise blue G-X is 4%, the dosage of bright yellow HF-4GL is 0.126%, the dosage of Jingren blue K-HL is 0.053%, Yuanming powder 60g / L, accelerator 2.5g / L after dyeing at 60℃ for 50min , drain off the dye liquor, wash 2 times with cold water, neutralize 1 time with 1% glacial acetic acid at 60°C, wash 2 times with cold water, soap with 1% soaping agent CSP at 80°C for 20min, heat at 98°C Wash 1 time with water, rinse with cold water, and then use 4% leveling agent 1227 to fix the color at 45°C for 20min.

Embodiment 2

[0012] Example 2: 40s pure cotton navy blue mesh cloth

[0013] The dosage of reactive turquoise blue G-X is 1.54%, the dosage of brilliant blue KN-R is 2.05%, the dosage of Wonder dark blue B-2GL is 0.02%, Yuanming powder 60g / L, sodium carbonate 20g / L after dyeing at 60℃ for 50min , drain off the dye liquor, wash 2 times with cold water, neutralize 1 time with 1% glacial acetic acid at 60°C, wash 2 times with cold water, soap with 1% soaping agent CSP at 80°C for 20min, heat at 98°C Wash with water for 1 time, rinse with cold water, and then use 2% leveling agent 1227 and 2% color fixing agent SF to fix the color at 45°C for 20min.

Embodiment 3

[0014] Example 3: 32S C60 / T40*21S C60 / T40 polyester cotton non-brushed cloth (red)

[0015] BH Red 2.5%, BH Yellow 0.68%, Jingren Blue K-HL 0.023%, Yuanming Powder 60g / L, Sodium Carbonate 20g / L, after dyeing at 60℃ for 50min, drain the dye solution, wash in cold water for 2 1% glacial acetic acid was neutralized at 60°C for 1 session, washed with cold water for 2 sessions, 1% soaping agent CSP was soaped at 80°C for 20 minutes, washed with 98°C hot water for 1 session, washed with cold water, and then Use 2% leveling agent 1227 and fix the color for 20min at 80℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com