Cobalt-based amorphous nanocrystal biphase metal fiber and preparation method thereof

An amorphous nanocrystalline and metal fiber technology is applied in the field of cobalt-based amorphous nanocrystalline dual-phase metal fibers and their preparation, which can solve the problems of poor tensile plasticity of cobalt-based amorphous fibers, and reduce process difficulty and process cost. , high tensile strength, simple principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

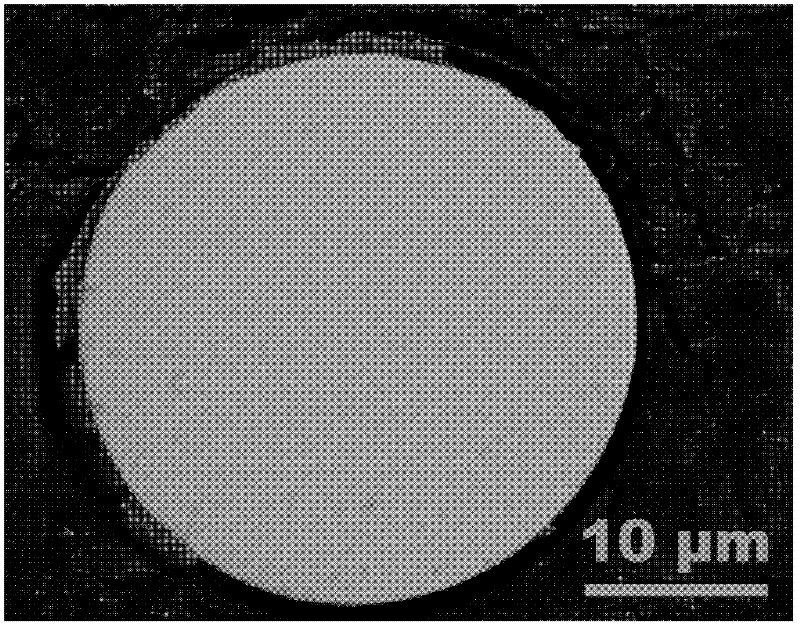

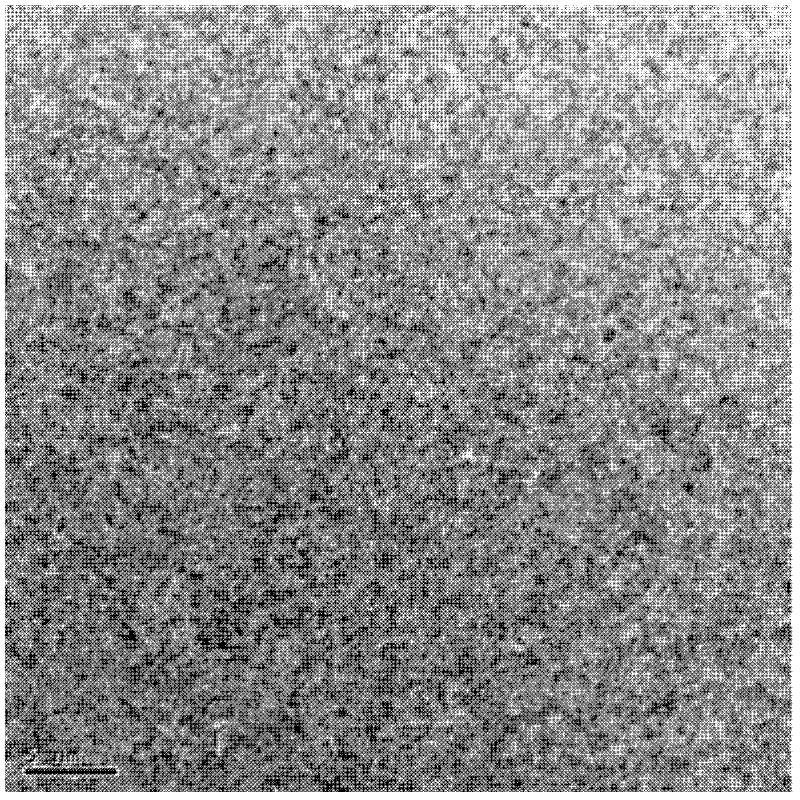

[0026] Embodiment 1: This embodiment is a cobalt-based amorphous nanocrystalline dual-phase metal fiber, and the nominal composition of the cobalt-based amorphous nanocrystalline dual-phase metal fiber is Co 68.15 Fe 4.35 Si 12.25 B 15.25 A crystalline phase with a size of 4-20 nanometers is dispersed on the amorphous matrix of the cobalt-based amorphous nanocrystalline dual-phase metal fiber, and the volume fraction of the crystalline phase is 5%-85%.

[0027]The yield strength of the cobalt-based amorphous nanocrystalline dual-phase metal fiber in this embodiment is 1208-2108 MPa, the fracture strength is 3044-3976 MPa, and the tensile plastic strain is 0.36%-1.64%.

[0028] The cobalt-based amorphous nanocrystalline dual-phase metal fiber of this embodiment has high thermal stability and high tensile strength, especially the amorphous nanocrystalline dual-phase metal fiber with significant plastic strain, so it has good application prospects .

specific Embodiment approach 2

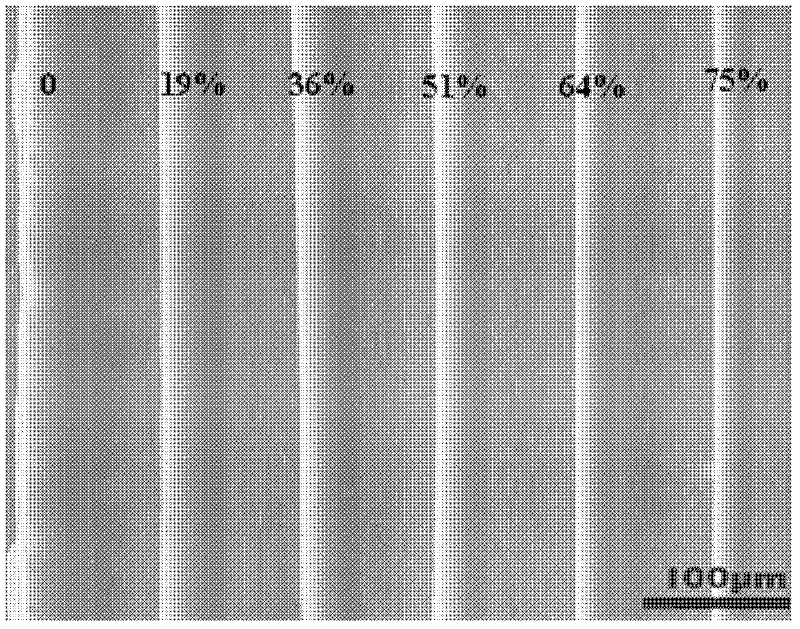

[0029] Specific embodiment two: This embodiment is the preparation method of cobalt-based amorphous nanocrystalline dual-phase metal fiber as described in specific embodiment one, which is realized by the following steps: 1. According to the nominal composition of Co 68.15 Fe 4.35 Si 12.25 B 15.25 Weigh Co, Fe, Si and B respectively, and then smelt the weighed Co, Fe, Si and B to make a preform with a diameter of 6-10mm, and then put the preform into the precision melt to draw the metal amorphous wire In the device, an amorphous metal fiber with a diameter of 55 to 65 microns is prepared; 2. The amorphous metal fiber prepared in step 1 is subjected to multi-pass cold drawing with a deformation amount of 5% to 75% using a diamond cold drawing die treatment to obtain cobalt-based amorphous nanocrystalline dual-phase metal fibers.

[0030] The yield strength of the cobalt-based amorphous nanocrystalline dual-phase metal fiber in this embodiment is 1208-2108 MPa, the fracture s...

specific Embodiment approach 3

[0036] Specific implementation mode three: the difference between this implementation mode and specific implementation mode two is that step one is specifically completed in the following steps: form Co according to the name 68.15 Fe 4.35 Si 12.25 B 15.25 Weigh Co, Fe, Si and B respectively, and then smelt the weighed Co, Fe, Si and B to make a preform with a diameter of 6-10mm, and then put the preform into the precision melt to draw the metal amorphous wire In the BN crucible of the device, the induction heating device is used to melt the preform to form a molten alloy with steamed bun-shaped protrusions, and then at 1150°C, the lifting device is used to raise the molten alloy at a speed of 90 μm / s until the molten alloy The top is in contact with a rotating metal roller with a linear speed of 15m / min, and is drawn and rounded into filaments to prepare amorphous metal fibers with a diameter of 55-65 microns; wherein the metal roller is a copper wheel with a diameter of 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com