Preparation method of P110-grade expansion tube for exploiting petroleum and gas

A technology for oil and natural gas and expansion pipes, which is applied to drill pipes, casings, drilling equipment, etc., can solve problems such as being unfavorable to the popularization and development of P110 high-grade steel expansion pipe technology, high alloy cost, and raising the cost of expansion pipe drilling technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The chemical composition weight percentage of selected raw material steel is as follows:

[0070] C: 0.15wt%~0.25wt%; Mn: 1.5wt%~2.0%; Si: 1.0wt%~1.5wt%; Al: 0.3wt%~1.0wt%; Nb: 0.05wt%~0.1wt%; Ti : 0.01wt%~0.02wt%; S: 0wt%~0.01wt%; P: 0wt%~0.015wt%.

[0071] The preferred ingredients are: C: 0.18wt%~0.25wt%, Mn: 1.5wt%~2.0wt%, Si: 1.0wt%~1.5wt%, Al: 0.3wt%~1.0wt%, Nb: 0.1wt% , Ti: 0.02wt%, S: 0.0075wt%, P: 0.0060wt%, the balance is Fe and unavoidable impurities.

[0072] The preferred production steps are as follows:

[0073] 1) Casting and rolling alloy plates according to the composition of the expansion tube described in the above technical solution;

[0074] 2) Coil the alloy plate, and then weld it to form an expansion tube;

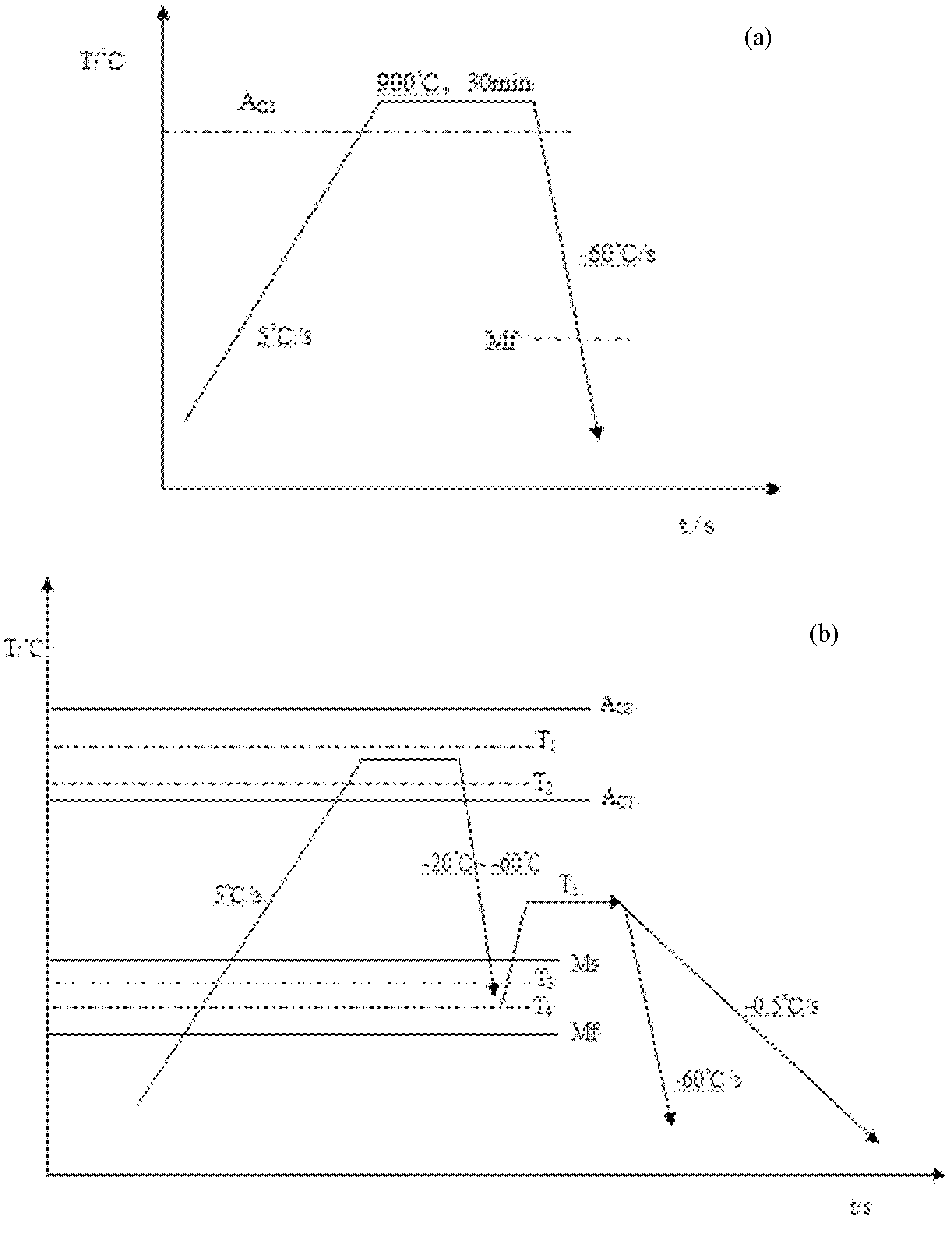

[0075] 3) Put the expansion tube into a resistance heating furnace for normalizing treatment, heat it to the set temperature at a heating rate of 5°C / s and hold it for a sufficient time to make it completely austenitized, and then use onl...

Embodiment 2

[0080] Select the preferred composition of the chemical composition of raw material steel with embodiment 1:

[0081] The preferred production steps are as follows:

[0082] 1) Casting and rolling alloy plates according to the composition of the expansion tube described in the above technical solution;

[0083] 2) Coil the alloy plate, and then weld it to form an expansion tube;

[0084] 3) Put the expansion tube into a resistance heating furnace for normalizing treatment, heat it to the set temperature at a heating rate of 5°C / s and hold it for a sufficient time to make it completely austenitized, and then use online spray quenching The expansion tube is quickly quenched into normal temperature water (cooling rate is about 60°C / s) to room temperature, so that the tube can be completely martensitic (complete quenching process);

[0085] 4) Put the quenched expansion tube in the resistance heating furnace again, heat it to the sub-temperature zone (two-phase zone) of 760~780 ...

Embodiment 3

[0089] Select the preferred composition of the chemical composition of raw material steel with embodiment 1:

[0090] The preferred production steps are as follows:

[0091] 1) Casting and rolling alloy plates according to the composition of the expansion tube described in the above technical solution;

[0092] 2) Coil the alloy plate, and then weld it to form an expansion tube;

[0093] 3) Put the expansion tube into a resistance heating furnace for normalizing treatment, heat it to the set temperature at a heating rate of 5°C / s and hold it for a sufficient time to make it completely austenitized, and then use online spray quenching The expansion tube is quickly quenched into normal temperature water (cooling rate is about 60°C / s) to room temperature, so that the tube can be completely martensitic (complete quenching process);

[0094] 4) Put the quenched expansion tube in the resistance heating furnace again, heat it to the sub-temperature zone (two-phase zone) of 760~780 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com