Dry-process dust-removing and dechlorination combined device for blast furnace gas

A dry dust removal and composite device technology, applied in the direction of dust collectors, etc., can solve the problems of corrosion of gas pipelines and auxiliary equipment, waste of waste heat resources of blast furnace gas, and consumption of large water resources, so as to improve reliability, stability and adaptability Strong, high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

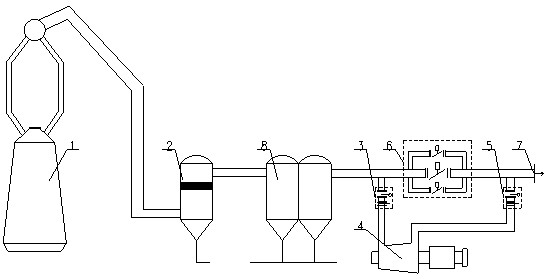

[0023] Embodiment 1: as figure 1 As shown, the top gas of the blast furnace 1 enters the granular bed dust collector 2 through the pipeline, and the clean blast furnace gas after dedusting, dechlorination, sulfur, ammonia and other impurities is merged into the clean gas pipeline network 7 after being generated by the power generation device 4, such as the power generation device 4 If it is not running, it will be merged into the clean gas pipeline network 7 after passing through the pressure reducing valve group 6.

[0024] The process of dust removal is as follows:

[0025] 1) Blast furnace raw gas (about 200°C) discharged from the top of blast furnace 1 enters granular bed dust collector 2 for dust removal and dechlorination, and the dry ash after dust removal can be directly recycled;

[0026] 2) The dust content of the blast furnace gas after the blast furnace gas dry dedusting and dechlorination composite device is ≤5mg / Nm 3 , the chlorine ion content in the gas conden...

Embodiment 2

[0028] Example 2, such as figure 2 Shown: different from Example 1, the particle bed dust collector 2 is used as a blast furnace gas coarse dust removal device, and then a dry fine dust removal device 8 is additionally provided, and the fine dust removal device 8 is a bag filter, an electric dust collector, Metal dust collector or Shuoyaki plate dust collector.

Embodiment 3

[0029] Example 3, such as image 3 As shown: the difference from Example 2 is that a coarse dust removal device 9 is provided before the granular bed dust collector 2, and the rough dust removal device 2 is a gravity dust collector, a cyclone dust collector or a ceramic high temperature dust collector.

[0030] The present invention adopts blast furnace gas dry dedusting and dechlorination composite device, and introduces a granular bed deduster into the dry dedusting process, which completely retains the advantages of the traditional dry dedusting process, and has the following salient features: Chlorine particles, desulfurization particles, deamination particles and hygroscopic particles, dechlorination, desulfurization, deamination, moisture absorption. The dust removal filter material of the particle bed dust collector can use particles with a particle size of less than 10mm (such as perlite, quartz sand or dust removal ash); the adsorbent can use a composite active compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com