Benzoxazine intermediate containing sulfonyl polyphenol and preparation method and use thereof

A technology of benzoxazine and intermediate, applied in the field of thermosetting resin and its preparation, can solve the problems of poor solubility, high curing temperature, easy precipitation, etc., and achieve the effect of low cost and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

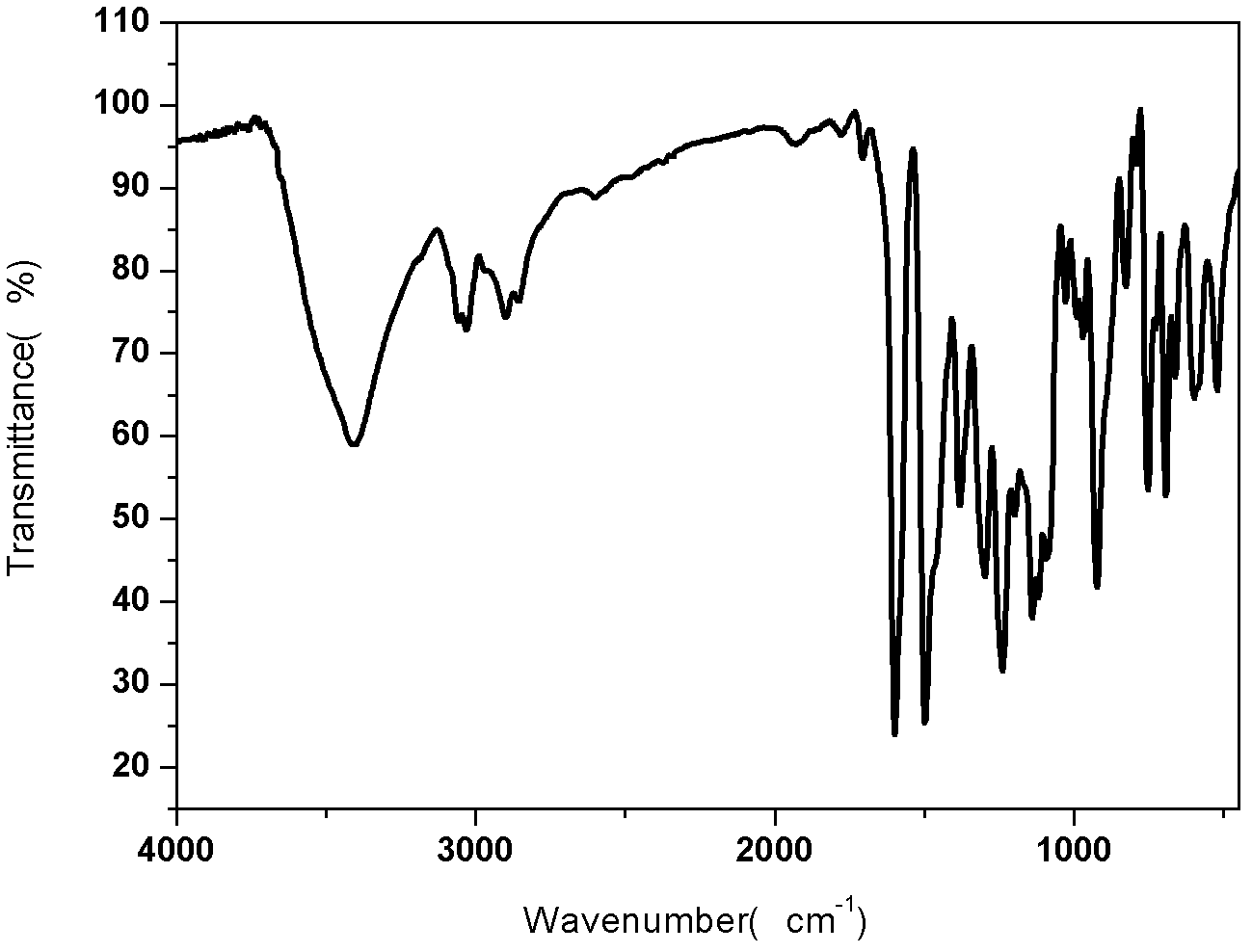

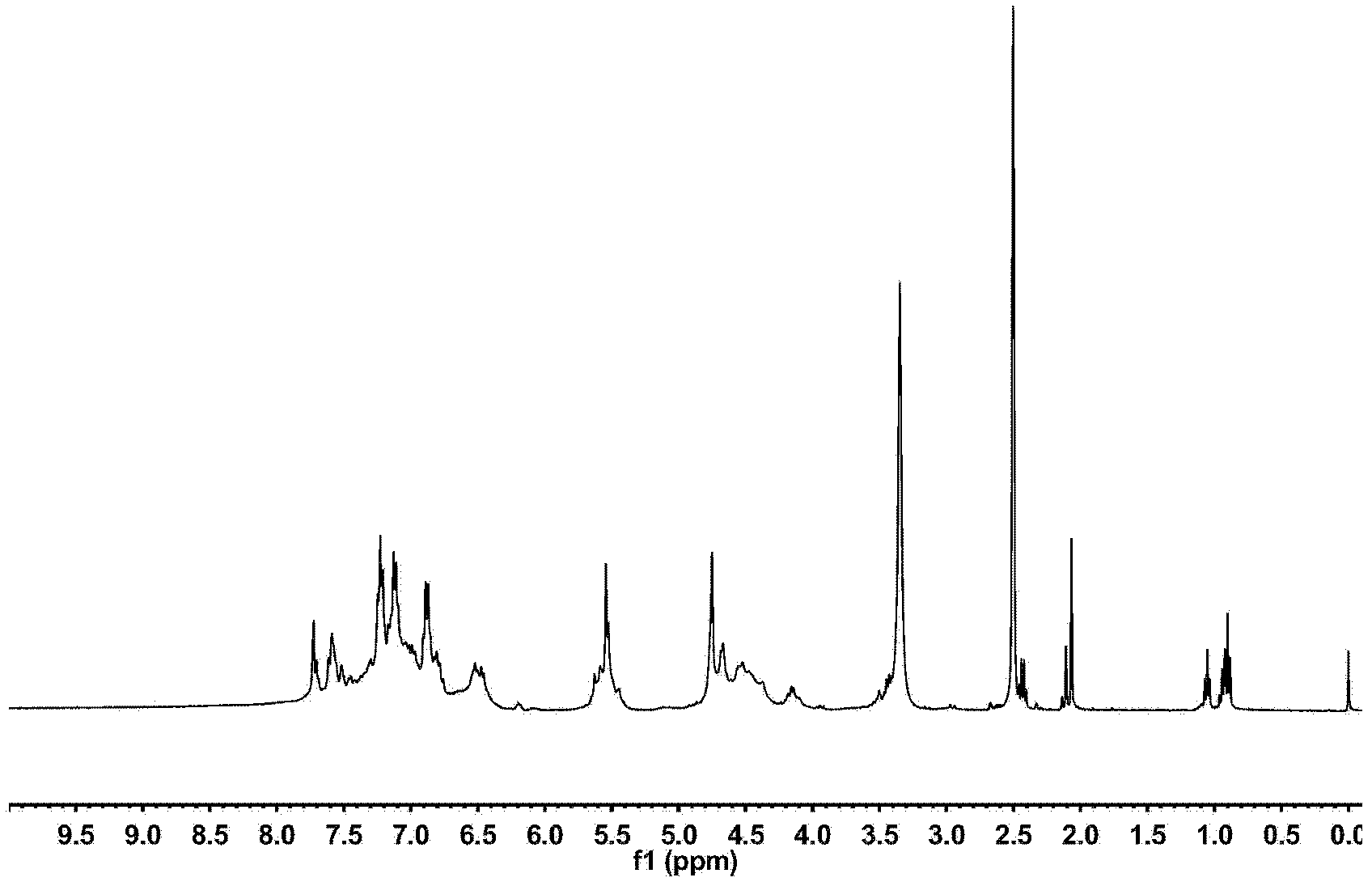

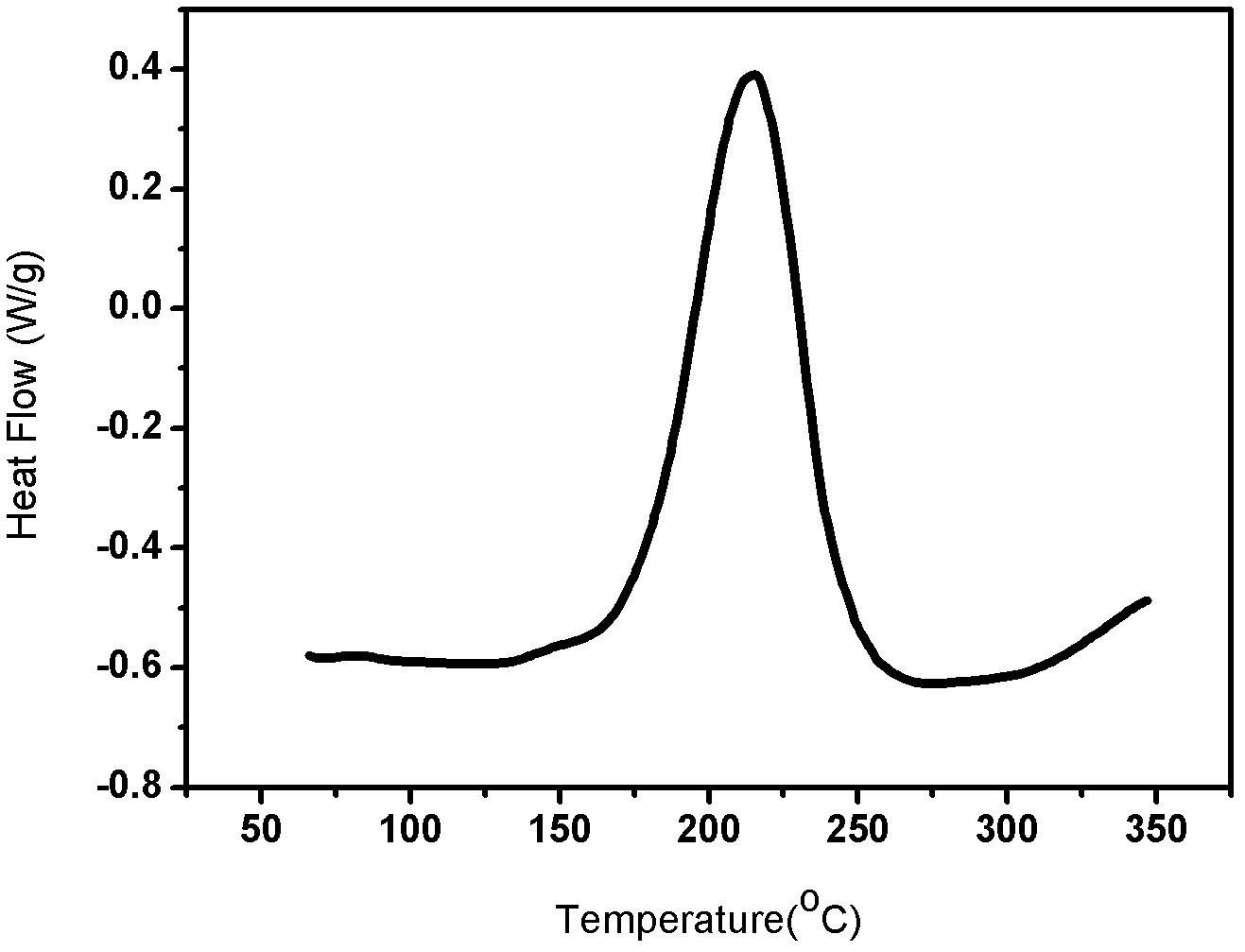

[0045] 24 grams of paraformaldehyde, 28 grams of toluene, 56 grams of ethanol and 4,4-dihydroxydiphenylsulfone 79.97%, 2,4-dihydroxydiphenylsulfone and 2,2-dihydroxydiphenylsulfone 15.25%, three Add 50 grams of sulfone group-containing polyphenols containing 3.41% hydroxytriphenyldisulfone and tetrahydroxytetraphenyltrisulfone to a three-necked bottle for dissolution, and adjust the pH value to 9 with NaOH solution. Then, a mixed solution of 28 g of toluene and 37.2 g of aniline was added dropwise at a temperature of 70° C. for 2 hours. React at a temperature of 80° C. for 6 h, and wash with water to obtain a light brown transparent solution of a sulfone group-containing polyphenol type benzoxazine intermediate. Infrared spectrum characterization: oxazine ring (923cm -1 ), sulfone group (1139cm -1 and 1298cm -1 ); NMR characterization: 4.75ppm (Ar-CH 2 -N) and 5.54ppm (O-CH 2-N). The gelation time at 180°C was 7 minutes and 18 seconds; the exothermic peak temperature of ...

Embodiment 2

[0047] 35 grams of paraformaldehyde, 170 grams of ethanol and 4,4-dihydroxydiphenylsulfone 76.97%, 2,4-dihydroxydiphenylsulfone and 2,2-dihydroxydiphenylsulfone 17.25%, trihydroxytriphenylsulfone Add 75 grams of sulfone group-containing polyphenols of 4.12% disulfone and tetrahydroxytetraphenyltrisulfone into a three-necked bottle for dissolution, and adjust the pH value to 9 with NaOH solution. Then 55 g of aniline were added. Raise the temperature to 50°C for 1 h, then raise the temperature to the boiling point of ethanol for 5 h, cool to room temperature after the reaction, the solid product precipitates, filters, washes, and dries to obtain a light yellow powder. The gelation time at 180°C was 5 minutes and 13 seconds.

Embodiment 3

[0049] Paraformaldehyde 75 grams, dioxane 230 grams and 4,4-dihydroxydiphenyl sulfone 73.07%, 2,4-dihydroxydiphenyl sulfone and 2,2-dihydroxydiphenyl sulfone 17.75%, trihydroxy Add 150 grams of sulfone group-containing polyphenols of 7.90% triphenyldisulfone and tetrahydroxytetraphenyltrisulfone into a three-necked bottle for dissolution, and adjust the pH value to 9 with NaOH solution. Then 110 g of aniline were added. Raise the temperature to 50°C for 1 hour, then raise the temperature to 80°C for 5 hours, cool to room temperature after the reaction, the solid product is precipitated, filtered, washed, and dried to obtain a light yellow powder. The gelation time at 180°C was 3 minutes and 48 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com