Low cis-polybutadiene rubber as well as preparation method and application thereof

A polybutadiene rubber, low-cis technology, applied in the field of low-cis polybutadiene rubber, can solve the problems that do not involve coupling polymer Mooney viscosity and SV value, and achieve low SV value, high threshold Ni viscosity, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 (Basic molecular weight of the first kettle design is 55000)

[0072] Under the protective atmosphere of high-purity nitrogen, the residence time of the system is 70 minutes, and 2706 g / h of raffinate, 544 g / h of 1,3-butadiene, 0.325 g / h of tetrahydrofuran, and 0.633 g / h of n-butyllithium are continuously added to the first kettle. h and 1,2-butadiene 0.978g / h. Adjust and control the polymerization reaction temperature and reaction pressure to be 60°C and 0.3-0.4MPa respectively, so as to make the 1,3-butadiene react. After the first kettle was stabilized, 0.386 g / h of silicon tetrachloride was continuously added to the second kettle.

[0073]Add 0.315 g / h terminator isopropanol to the outlet of the last kettle (namely the second kettle) to terminate the reaction, and add 0.2% by weight of the monomer Irganox 1520, and then carry out steam coagulation and desolvation treatment on the glue.

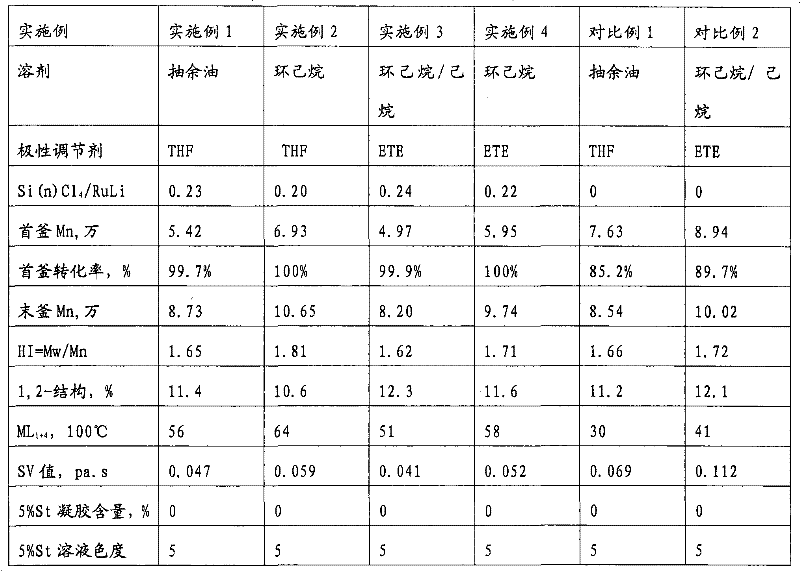

[0074] The molecular parameters (molecular weight and molecular w...

Embodiment 2

[0075] Example 2 (Basic molecular weight of the first kettle design is 70000)

[0076] Under the protective atmosphere of high-purity nitrogen, the residence time of the system is 40 minutes, and 5670 g / h of cyclohexane, 952 g / h of 1,3-butadiene, 0.567 g / h of tetrahydrofuran, and 0.87 g / h of n-butyllithium are continuously added to the first kettle. h and 1,2-butadiene 1.701g / h. Adjust and control the polymerization reaction temperature and reaction pressure to be 70° C. and 0.3-0.4 MPa respectively, so as to make the 1,3-butadiene react. After the first kettle was stabilized, 0.462 g / h of silicon tetrachloride was continuously added to the second kettle.

[0077] Add 0.432g / h terminator isopropanol to the outlet of the final kettle to terminate the reaction, and add 0.2% by monomer weight of anti-aging agent Irganox 1520, and then perform steam coagulation and desolventization treatment on the glue.

[0078] The analysis test results are shown in Table 1.

Embodiment 3

[0079] Example 3 (Basic molecular weight of the first kettle design is 50000)

[0080] Under the protective atmosphere of high-purity nitrogen, the residence time of the system is 30 minutes, and the mixed solvent (cyclohexane and n-hexane, weight ratio is 88:12) 6286g / h and 1,3-butadiene 1292g / h are continuously added to the first kettle , ethyl tetrahydrofurfuryl ether 0.045g / h, n-butyllithium 1.653g / h and 1,2-butadiene 2.268g / h. The polymerization reaction temperature and reaction pressure are controlled to be 90° C. and 0.3-0.4 MPa respectively, so that 1,3-butadiene is reacted. After the first kettle was stabilized, 1.054 g / h of silicon tetrachloride was continuously added to the second kettle.

[0081] Add 0.922 g / h terminator isopropanol to the outlet of the final kettle to terminate the reaction, and add 0.2% by weight of the monomer Irganox 1520, and then carry out steam coagulation and desolvation treatment on the glue.

[0082] The analysis test results are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com