Preparation method for ocean engineering reinforced concrete silane emulsion protective agent

A technology of reinforced concrete and silane emulsion, which is applied in the anticorrosion field of marine engineering materials, can solve the problems of direct emulsification without silane monomer and difficult emulsification, and achieve the effects of shortening the complete curing time, small molecular weight, and low volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

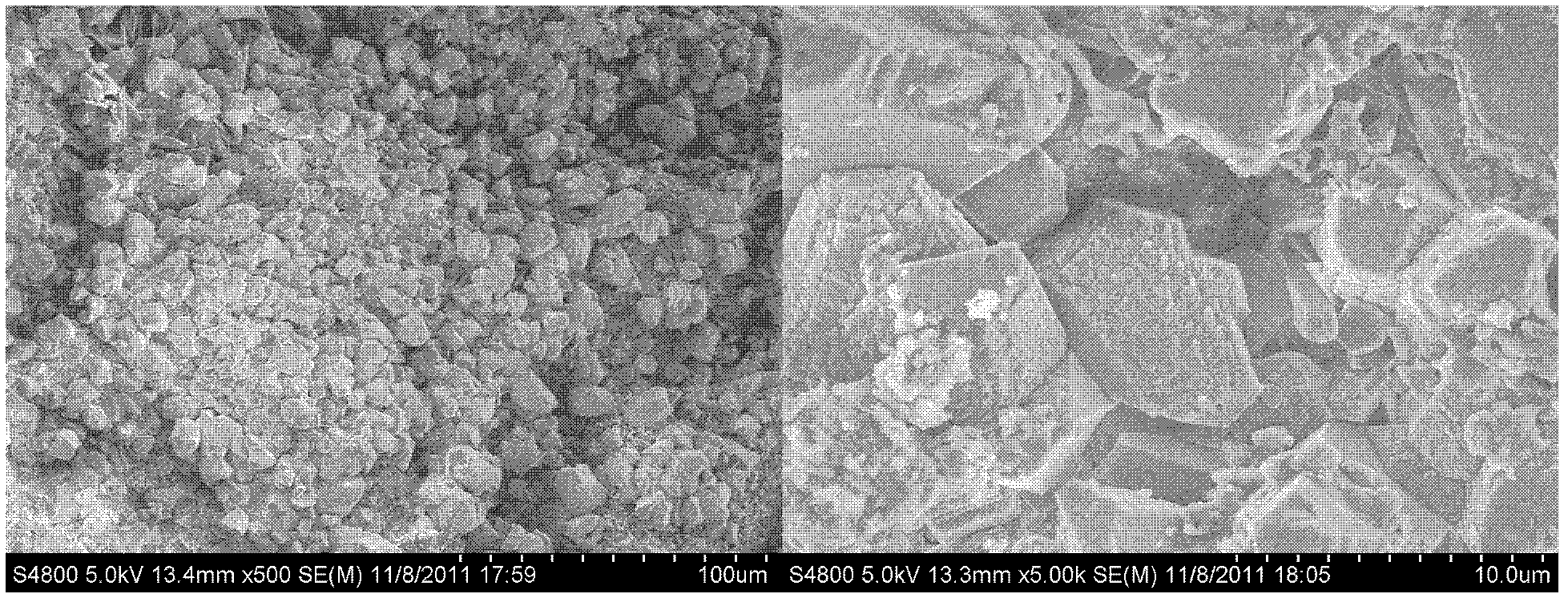

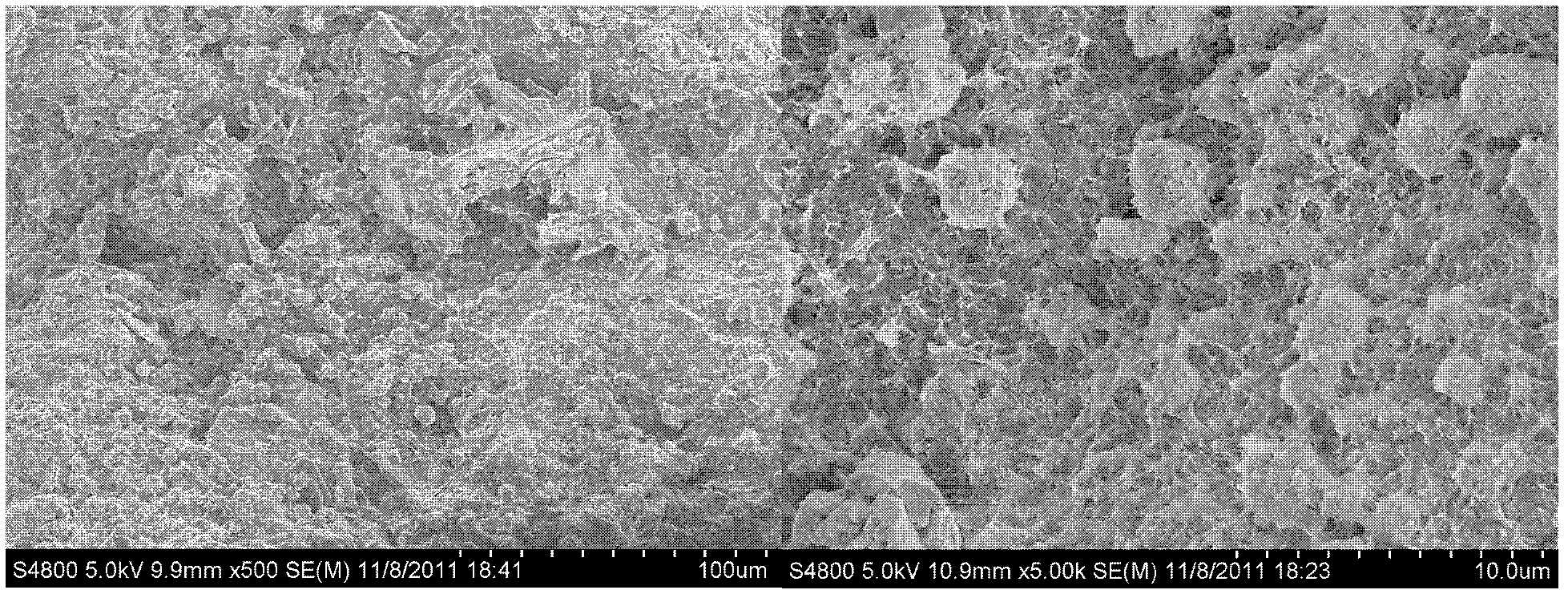

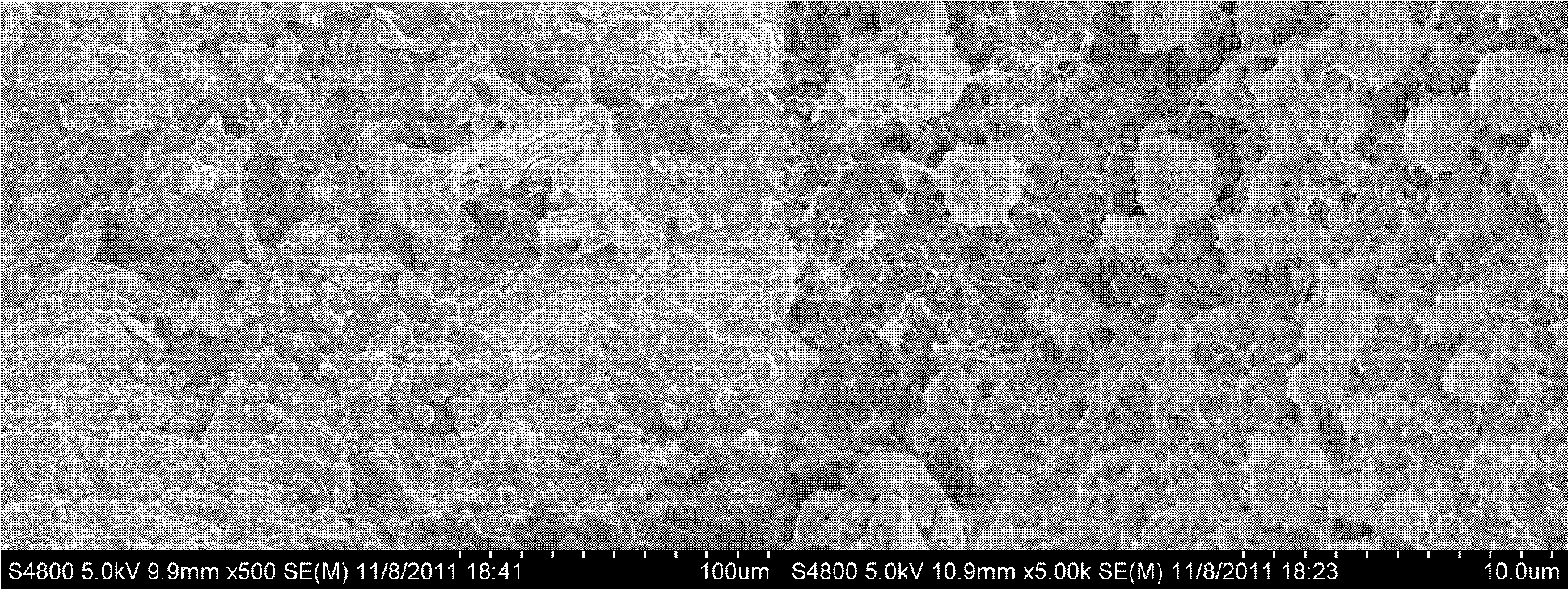

Image

Examples

Embodiment Construction

[0025] The preparation method of the marine engineering reinforced concrete silane emulsion protective agent in the present invention comprises the following steps: stirring and dissolving the emulsifier in advance with 40 to 80 parts by mass of deionized water in the reactor, and slowly Add 20 to 60 parts by mass of silane monomer, and then emulsify at 30 to 60°C for 6 to 12 hours under stirring at 400 to 1200 rpm to obtain a uniform and stable micro-nano emulsion, which is the product; the silane monomer It is a silane monomer with at least three ethoxy groups; the emulsifier includes at least two non-ionic emulsifiers, and the total addition amount is 2-10% of the silane monomer. Among the emulsifiers, any nonionic emulsifier is used as the main emulsifier, and other nonionic emulsifiers are used as auxiliary emulsifiers, and the mass ratio of the main emulsifier to the auxiliary emulsifier is 2:1 to 6:1 .

[0026] The test data in each embodiment sees the following table:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com