Method and device for recovering indigoid dye

A technology of indigo dye and recovery equipment, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., to achieve high recovery efficiency and good sewage treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

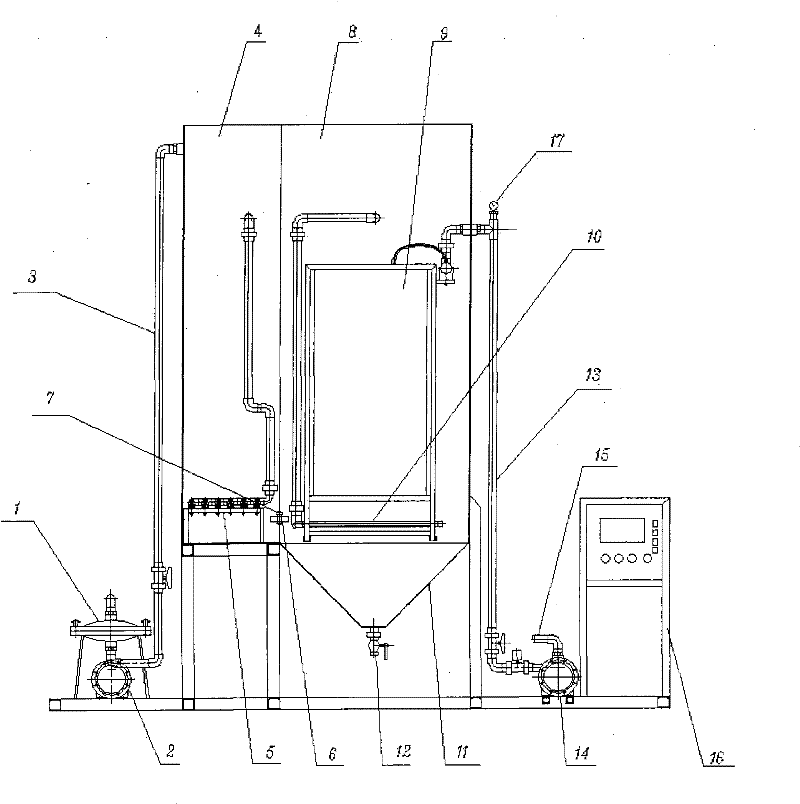

Image

Examples

Embodiment 1

[0020] A kind of method that indigo dye reclaims, it comprises the steps:

[0021] 1) Printing and dyeing wastewater enters the filter for pre-filtration to remove fibrous substances and large particles in the water;

[0022] 2) The filtered waste water is pumped into the oxidation tank, and the oxidation tank is blown and aerated to crystallize the leuco indigo, and add sulfuric acid through the PLC controller to maintain the pH in the tank at 8;

[0023] 3) When the solenoid valve is opened, the water in the oxidation tank enters the filter tank, and the flat membrane module is aerated in the filter tank to prevent solid particles from aggregating on the membrane to reduce the membrane flux. The PLC controller controls the addition of sulfuric acid to maintain the pH in the tank at 6;

[0024] 4) Sequence of membrane module suction filtration: run for 3 minutes, pause for 2 minutes;

[0025] 5) the indigo concentrate after suction filtration for a certain period of time is...

Embodiment 2

[0029] A kind of method that indigo dye reclaims, it comprises the steps:

[0030] 1) Printing and dyeing wastewater enters the filter for pre-filtration to remove fibrous substances and large particles in the water;

[0031] 2) The filtered wastewater is pumped into the oxidation pool, and the oxidation pool is blown and aerated to crystallize the leuco indigo, and add sulfuric acid through the PLC controller to maintain the pH in the pool at 7;

[0032] 3) When the solenoid valve is opened, the water in the oxidation tank enters the filter tank, and the flat membrane module is aerated in the filter tank to prevent solid particles from accumulating on the membrane and reduce the membrane flux. The PLC controller controls the addition of sulfuric acid to maintain the pH in the tank at 4;

[0033] 4) Sequence of membrane module suction filtration: run for 3 minutes, pause for 1 minute;

[0034] 5) the indigo concentrate after suction filtration for a certain period of time is...

Embodiment 3

[0038] A kind of method that indigo dye reclaims, it comprises the steps:

[0039] 1) Printing and dyeing wastewater enters the filter for pre-filtration to remove fibrous substances and large particles in the water;

[0040] 2) The filtered waste water is pumped into the oxidation tank, and the oxidation tank is blown and aerated to crystallize the leuco indigo, and add sulfuric acid through the PLC controller to maintain the pH in the tank at 6;

[0041] 3) When the solenoid valve is opened, the water in the oxidation tank enters the filter tank, and the flat membrane module is aerated in the filter tank to prevent solid particles from accumulating on the membrane and reduce the membrane flux. The PLC controller controls the addition of sulfuric acid to maintain the pH in the tank at 5;

[0042] 4) Sequence of membrane module suction filtration: run for 4 minutes, pause for 3 minutes;

[0043] 5) the indigo concentrate after suction filtration for a certain period of time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com