Inorganic/organic composite porous lithium battery diaphragm and preparation method thereof

A lithium battery separator and porosity technology, which is applied in the field of inorganic/organic composite polypropylene (PP) non-woven fabric-based lithium battery separator and its preparation, can solve the trouble of making PE-PP sheath core composite fibers and is not suitable for lithium batteries Diaphragm, non-woven fabric with large pore size and other problems, to achieve the effects of excellent charge-discharge cycle performance, improved mechanical strength, and high liquid absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 6

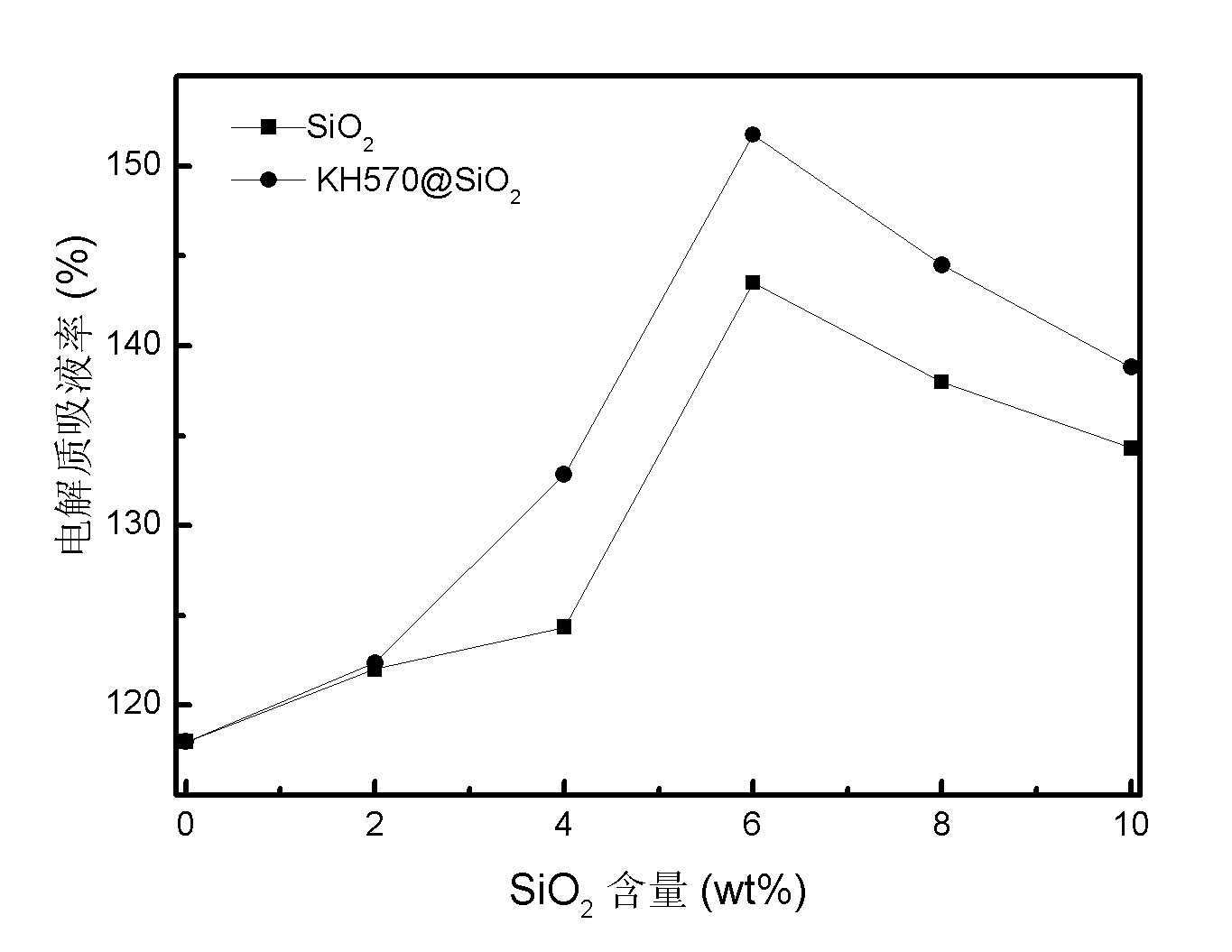

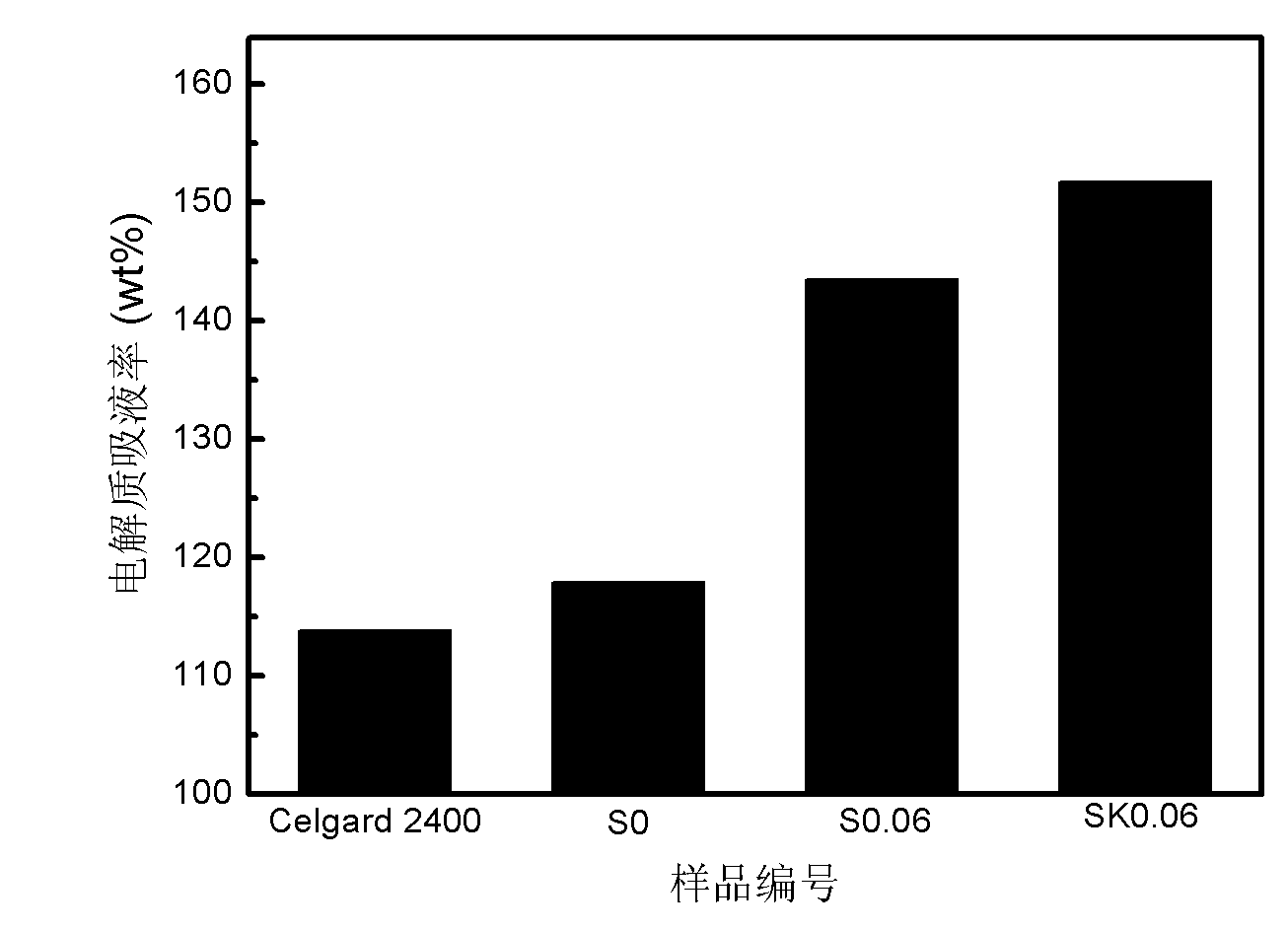

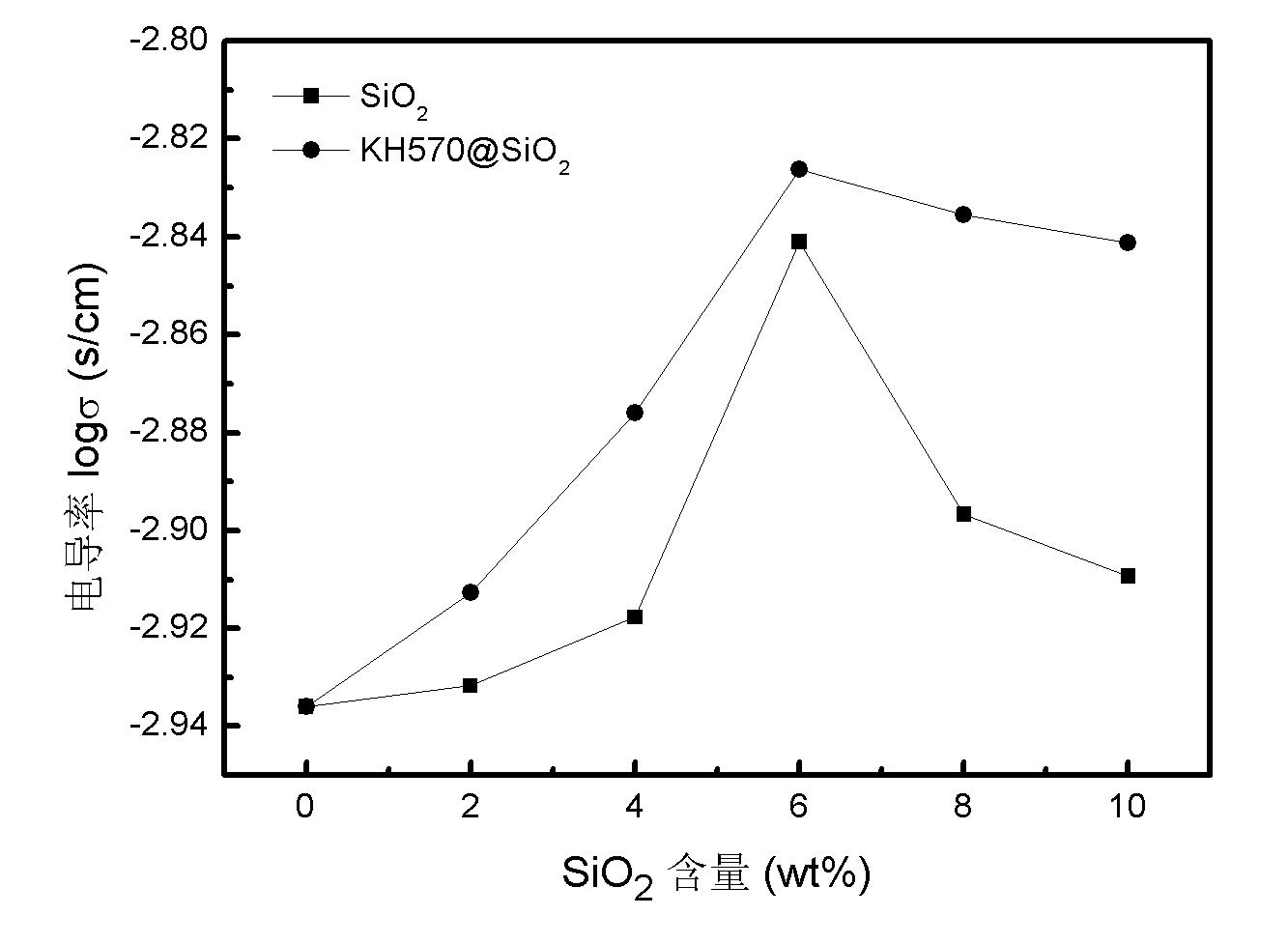

[0038] Embodiments one to six: SiO 2 Preparation of / PVdF-HFP / PP non-woven composite lithium battery separator

Embodiment 1

[0039] Example 1: Preparation of PVdF-HFP / PP non-woven composite diaphragm

[0040] Dry the reaction bottle and stirring bar in an oven at 120 °C for at least 6 hours, and dry polyvinylidene fluoride-hexafluoropropylene copolymer (PVdF-HFP, Solvay, trade name Solef 21216 / 1001) at 80 °C for at least 6 hours. Let dry for 6 hours. Cool to room temperature after taking it out, and weigh it immediately for use.

[0041] Weigh 4.000 grams of PVdF-HFP and 0.400 grams of hydrophilic agent F127, put them in a round bottom flask, then add 4.000 grams of DMF (N,N-dimethylformamide) and 36.000 grams of acetone, and stir at room temperature for 1 hour , and then heated to 60 ° C and continued to stir for 2 hours to obtain a uniform mixed solution, which was cooled to room temperature.

[0042] PP non-woven fabric of suitable size (approximately 9 mm x 12 mm in area) is placed on a dry PE board, pipette the mixed solution onto the non-woven fabric with a rubber dropper, and use an adjusta...

Embodiment 2

[0043] Example 2: SiO 2 / PVdF-HFP / PP non-woven fabric (PVdF-HFP:SiO 2 =100: 2) Preparation of composite separator

[0044] Dry the reaction bottle and stirrer in an oven at 120 °C for at least 6 hours in advance, PVdF-HFP and SiO with a particle size of 18nm 2 Dry at 80°C for at least 6 hours. Cool to room temperature after taking it out, and weigh it immediately for use.

[0045] Weigh 4.000 g of PVdF-HFP, 0.080 g of SiO 2 and 0.400 grams of F127 in a round-bottomed flask, then added 4.000 grams of DMF (N,N-dimethylformamide) and 36.000 grams of acetone, stirred at room temperature for 1 hour, then raised the temperature to 60°C and continued to stir for 2 hours. A homogeneous mixed solution was obtained and cooled to room temperature.

[0046] PP non-woven fabric of suitable size (approximately 9 mm x 12 mm in area) is placed on a dry PE board, pipette the mixed solution onto the non-woven fabric with a rubber dropper, and apply the solution with an adjustable film appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com