UV Optical Delivery Systems for Wafer Dicing Equipment

A technology of cutting equipment and transmission system, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of LED chip light decay and life reduction, increase the difficulty of process exploration, and it is difficult to determine the cutting effect, etc., to achieve Effects of reducing irradiation intensity, improving convenience, and increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

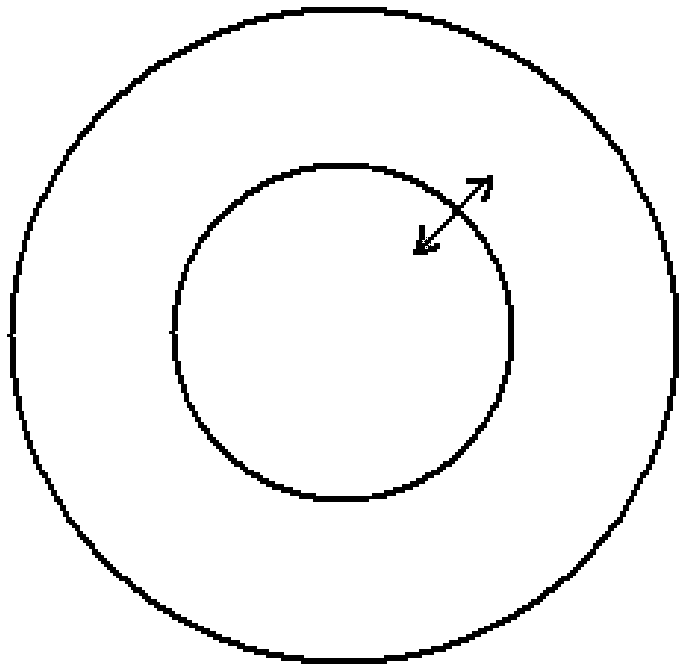

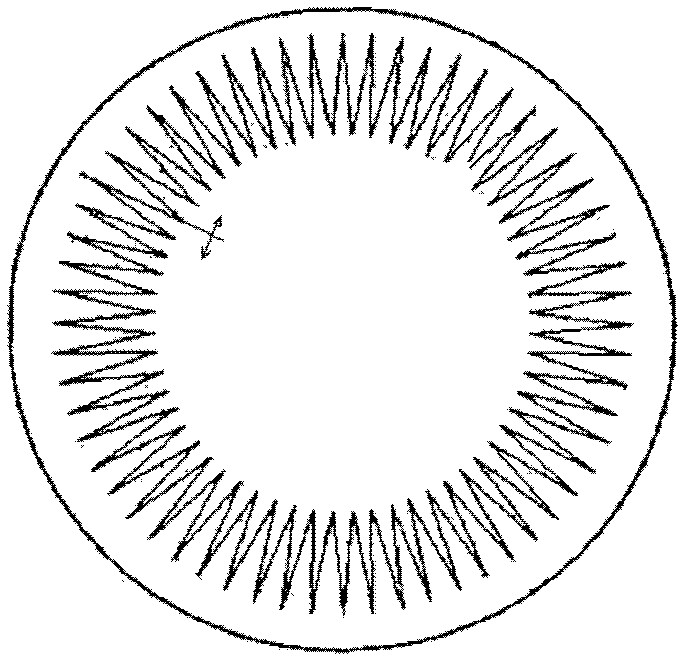

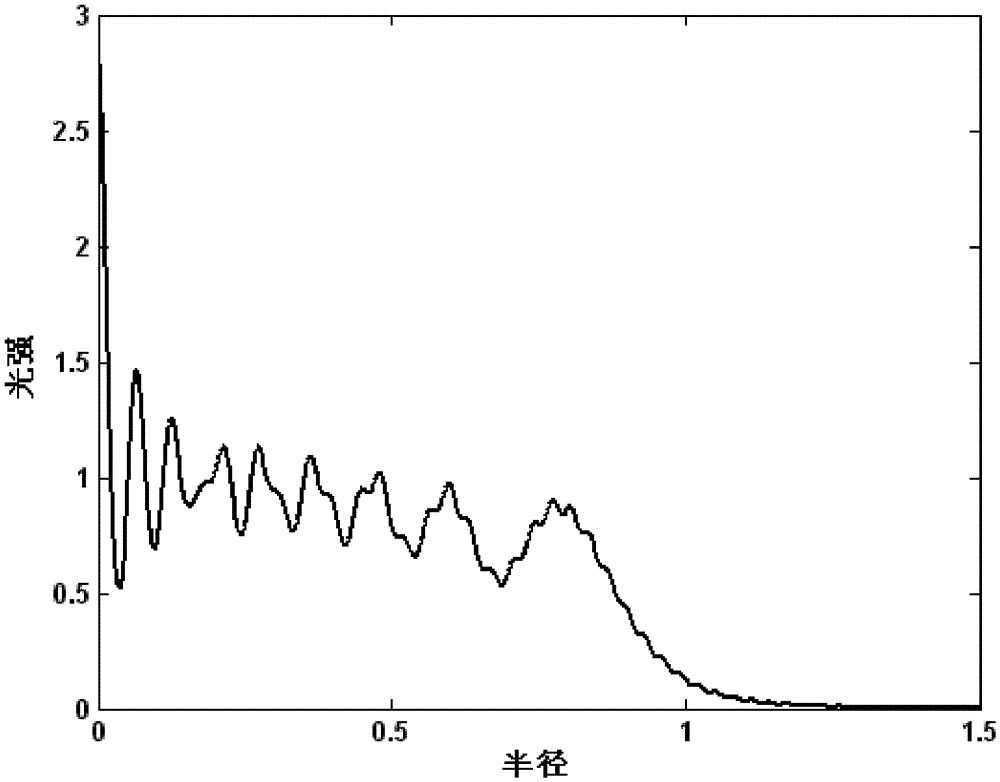

[0017] Figure 5 It is a schematic diagram of the structure of the ultraviolet laser transmission optical path. The laser output from the ultraviolet laser 1 passes through the λ / 2 wave plate 2 to rotate the polarization direction, and then passes through the polarizer 3 to analyze the radial polarization. A part of the laser light is reflected by the polarizer and then injected into the receiving bucket 4 to be received. The other part of the laser light is transmitted through the polarizer 3; the λ / 2 wave plate 2, the polarizer 3 and the receiving bucket 4 form a laser power adjustment module, which can conveniently adjust the laser power without changing the laser pulse width. The laser light passing through the polarizer 3 passes through the serrated diaphragm 5 and reflects a part of the laser light on the 45-degree beam splitter 6 and shoots it to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com