Process and device for high-temperature alloy fine-grain casting with composite electromagnetic fields

A superalloy and electromagnetic field technology, applied in the field of superalloy fine-grain casting process methods and devices, can solve the problem that the superalloy casting has limited solidification structure refinement effect, it is difficult to obtain superalloy fine-grain casting, and the upper surface of the molten metal fluctuates greatly. and other problems to achieve the effect of eliminating adverse effects, suppressing violent fluctuations, and reducing central shrinkage and segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

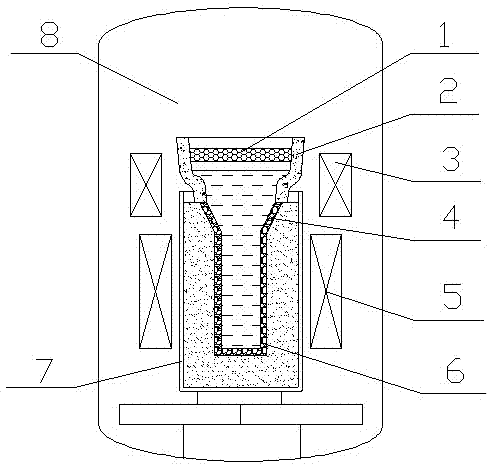

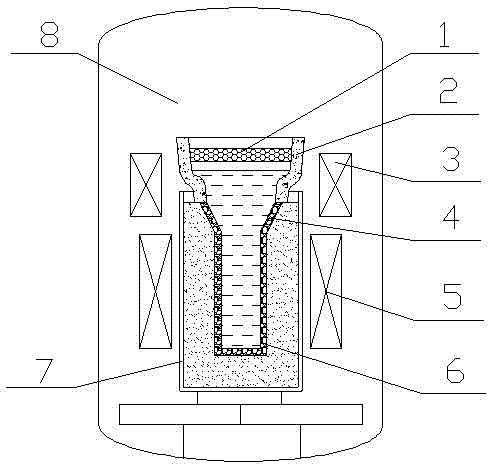

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The high-temperature alloy fine-grain casting device for applying a composite electromagnetic field in the present invention includes a vacuum intermediate frequency induction melting furnace 8, an austenitic stainless steel sand box 7 is arranged at the center of the vacuum intermediate frequency induction melting furnace 8, and on the outside of the austenitic stainless steel sand box 7, A DC electromagnetic field generator 3 with a magnetic induction intensity of 100-300mT is arranged 10-100 mm away from the upper end surface. On the outside of the austenitic stainless steel sandbox 7, a two-way low-frequency AC rotating electromagnetic field generator 5 with a frequency of 3-60 Hz and an input current of 60-200A is set at a distance of 20-250 mm from its lower end surface. On the upper part of the austenitic stainless steel sandbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com