A kind of upflow residual oil hydrotreating method

A technology of hydroprocessing and treatment method, which is applied in the treatment of hydrocarbon oil, petroleum industry, refining to remove heteroatoms, etc. It can solve the problems affecting the stable operation of catalyst performance, unstable catalyst bed, long service life, etc., and achieve long-term Stable catalytic performance, beneficial to conversion ability, stable upper temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, an upflow hydrogenation reactor is used to carry out the residual oil hydrotreating reaction. The upflow reactor is provided with three catalyst beds with a volume ratio of 1:1:1. Each catalyst bed is filled with 300 mL of catalyst, and the total amount of catalyst loaded is 900 mL. The hydrotreating catalyst FZC-11UA was used in the three catalyst beds, and the properties of the catalyst are shown in Table 1.

[0037] The feed used is a typical Middle East residual oil, and the hydrofining reaction is carried out in the upflow residual oil hydrogenation reactor, and the upflow hydrogenation oil is obtained after mainly removing impurities such as metals. The main process conditions are shown in Table 2. The properties of the hydrogenated oil obtained in the upflow reactor are shown in Table 3.

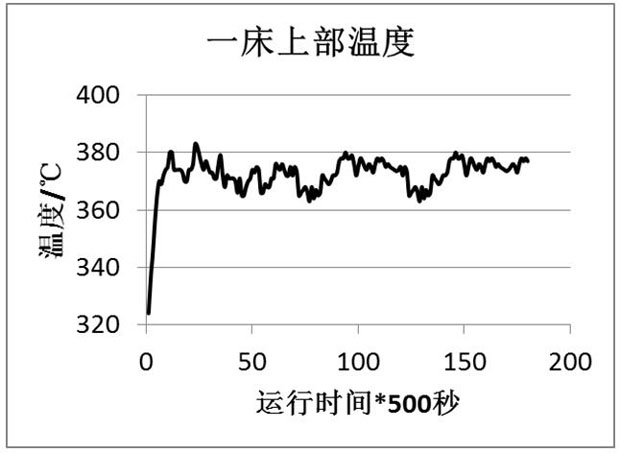

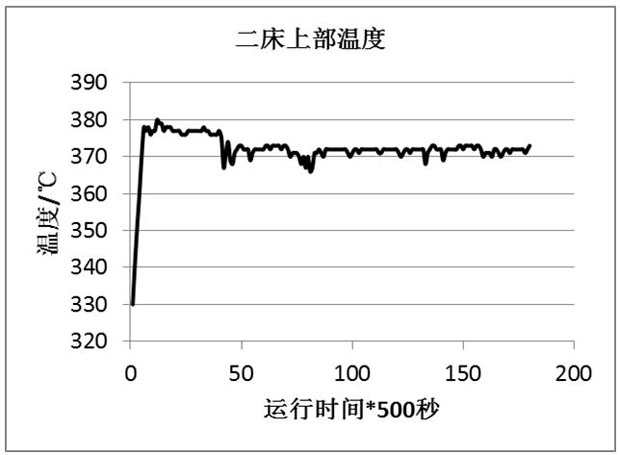

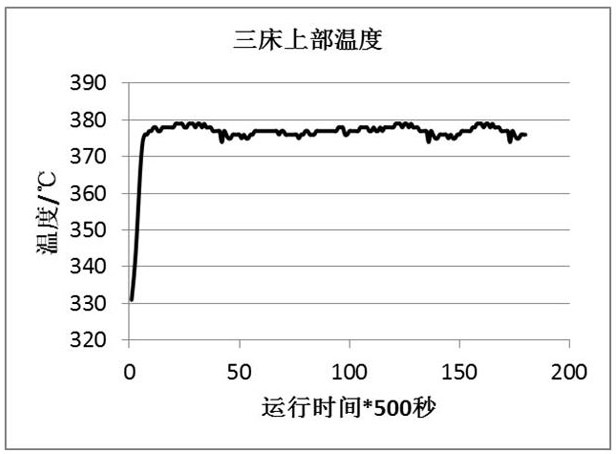

[0038] A material distributor and a hydrogen cooling pipe are arranged between the catalyst beds of the upflow hydrogenation reactor. And set thermocouples ...

Embodiment 2

[0050] In this example, an upflow hydrogenation reactor is used to carry out the residual oil hydrotreating reaction. The upflow reactor is equipped with three catalyst beds. Along the flow direction, the first catalyst bed is filled with 260 mL of catalyst, the second catalyst bed is filled with 300 mL of catalyst, and the third catalyst bed is filled with 340 mL of catalyst. The total amount is 900 mL. The three catalyst beds all use hydrotreating catalyst FZC-11UA.

[0051] The feed used is a typical Middle East residual oil, and the hydrofining reaction is carried out in the upflow residual oil hydrogenation reactor, and the upflow hydrogenation oil is obtained after mainly removing impurities such as metals. The main process conditions are shown in Table 2. The properties of the hydrogenated oil obtained in the upflow reactor are shown in Table 4.

[0052] A material distributor and a hydrogen cooling pipe are arranged between the catalyst beds of the upflow hydrogenat...

Embodiment 3

[0054] In this example, an upflow hydrogenation reactor is used to carry out the residual oil hydrotreating reaction. The upflow reactor is equipped with three catalyst beds. Along the flow direction, the first catalyst bed is filled with 300 mL of catalyst, the second catalyst bed is filled with 300 mL of catalyst, and the third catalyst bed is filled with 300 mL of catalyst. The total amount is 900 mL. The three catalyst beds all use hydrotreating catalyst FZC-11UB.

[0055] The feed used is a typical Middle East residual oil, and the hydrofining reaction is carried out in the upflow residual oil hydrogenation reactor, and the upflow hydrogenation oil is obtained after mainly removing impurities such as metals. The main process conditions are shown in Table 2. The properties of the hydrogenated oil obtained in the upflow reactor are shown in Table 4.

[0056] A material distributor and a hydrogen cooling pipe are arranged between the catalyst beds of the upflow hydrogenat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com