Non-cyanide ore dressing method for gold-copper-lead sulfide ore

A technology of lead sulfide ore dressing method, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low metal recovery rate, large environmental pollution, high production cost, etc., and achieve high recovery rate of copper and lead, Significant economic benefits and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

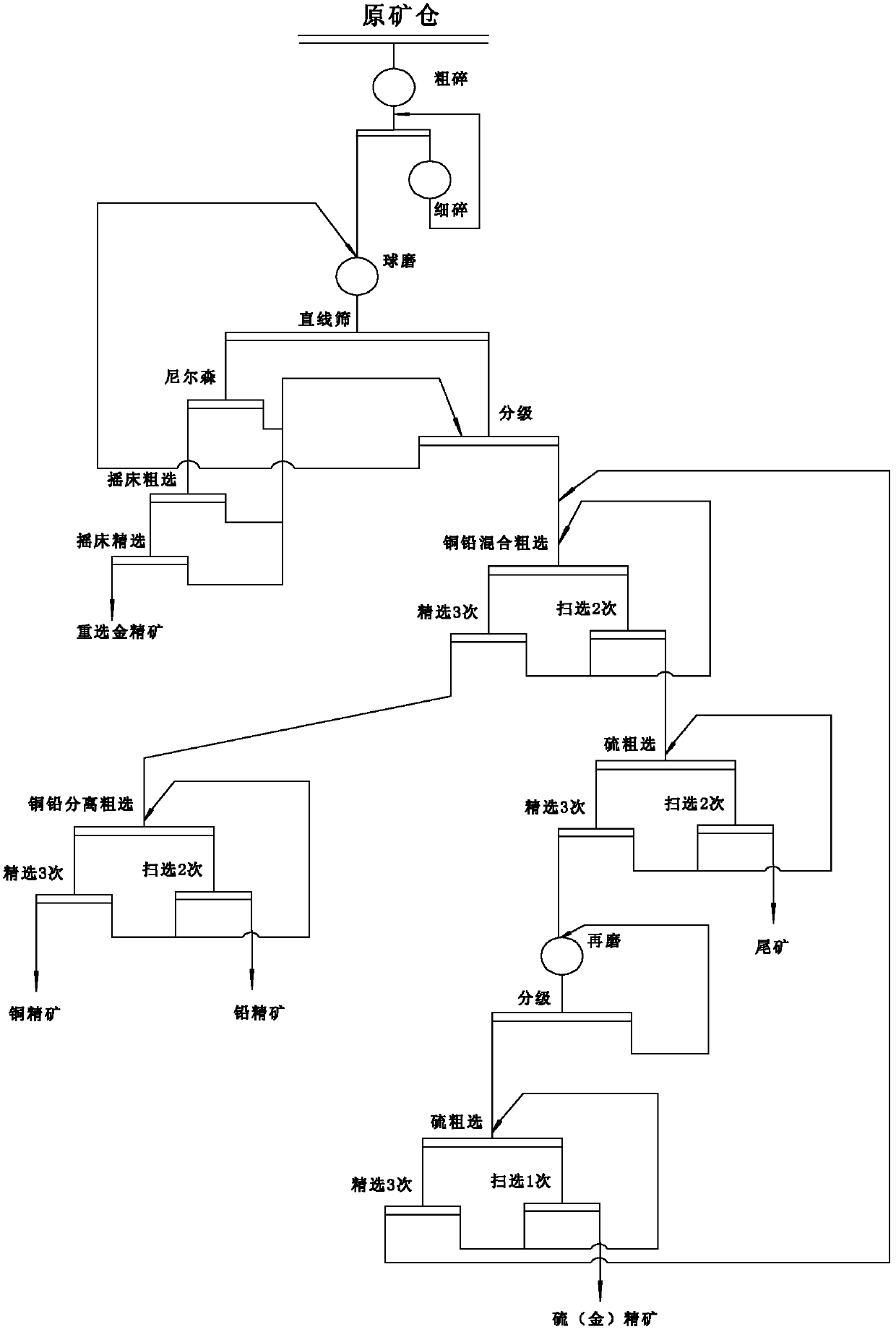

[0026] The cyanide-free beneficiation method of gold-copper-lead sulfide ore mainly includes the following four processes:

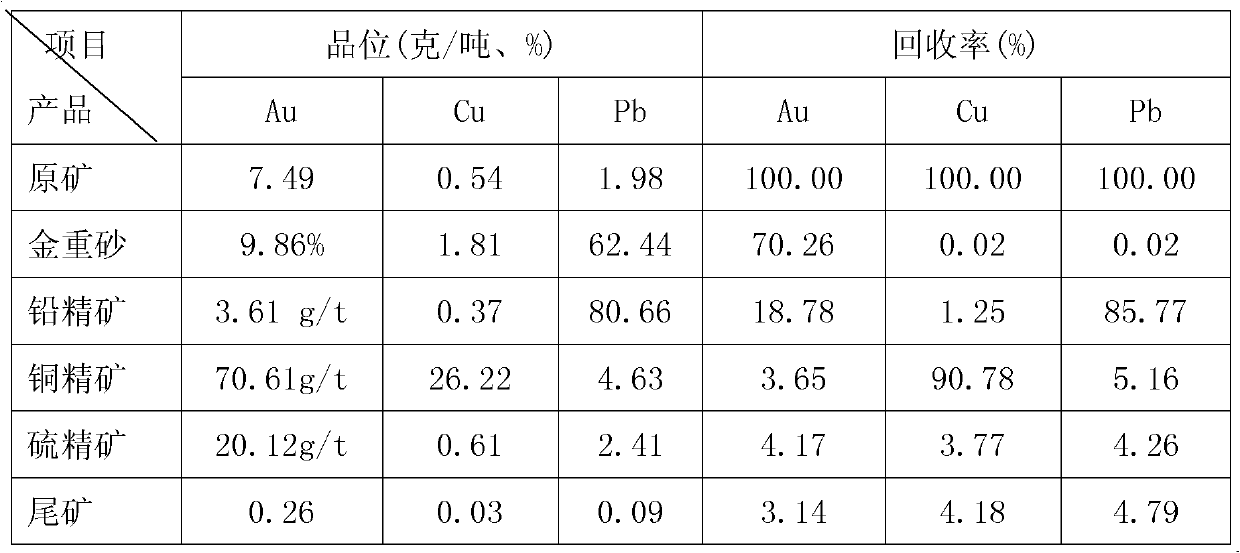

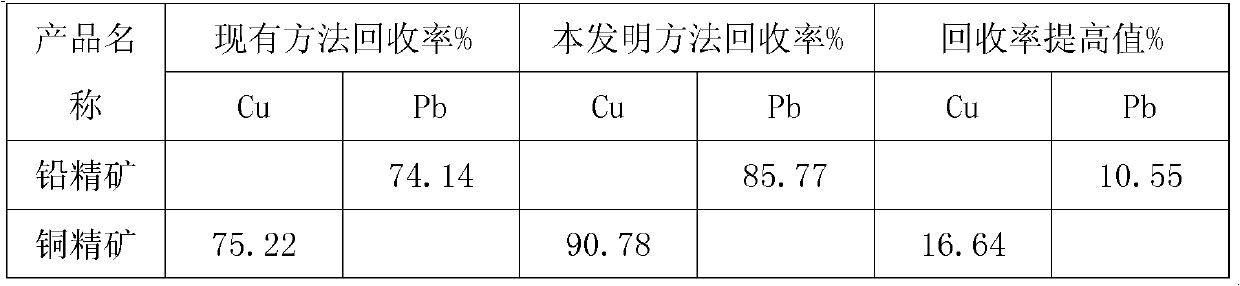

[0027] First: Using the combination of Nielsen and shaking table, under the condition of rough grinding of raw ore to -200 mesh 65%, select the gold concentrate with coarse grain grade as the main body, the gold grade is as high as 10%, and the gold recovery rate is as high as 70%; The recovery of fine-grained gold minerals does not require cyanidation, and directly enters the flotation system, and is enriched in copper, lead, and pyrite concentrates through separation flotation, eliminating the cyanide ions and heavy metals produced by the original cyanide gold extraction process Ion pollution to the environment;

[0028] Second: Copper-lead mixed flotation is to achieve efficient separation of copper-lead minerals and pyrite minerals under the pH value of the natural pulp, using the selectivity of the combined collector for minerals and the difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com