High-density polyethylene hollow fiber microporous membrane and preparation method thereof

A high-density polyethylene and microporous membrane technology, applied in the field of membrane separation, can solve the problems of poor mechanical properties of fiber membranes, increased equipment investment, environmental pollution, etc., and achieve the effect of high permeation flux and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

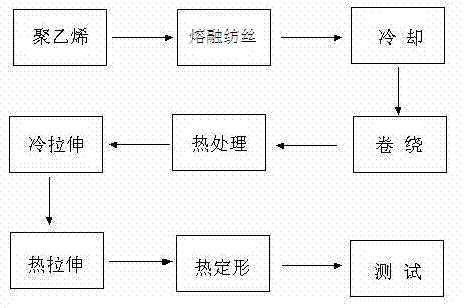

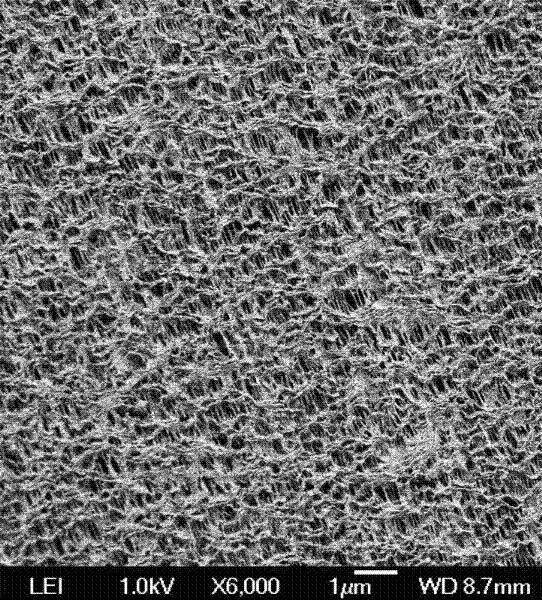

[0066] Select the molecular weight as 1.0(Mn)×10 -5 Polyethylene resin with a density of 0.995kg / m 3 , Melt index 1.1; process flow: melt spinning, cooling, winding, heat treatment, cold stretching, hot stretching, heat setting, testing. After the polyethylene resin is melted, the polyethylene melt is extruded from the spinneret by the screw extruder, and stretched under the action of winding tension. The melt spinning temperature is 180°C in zone 1, 200°C in zone 2, and 220°C in zone 3; the spinning / drawing speed ratio is 3000; the cooling air height is 330mm, and the cooling air temperature is 10±5°C; the obtained polyethylene hollow fiber is microporous The membrane properties are as follows: porosity 79.53%, pore diameter 40.6nm, specific surface area 451.39m 2 / g, apparent density 0.681g / cm 3 , breaking strength 58.6MPa, N 2 Flux 49×103L / m 2 ·h·0.1MPa, the water flux is 227L / m 2 · h · 0.1MPa.

Embodiment 2

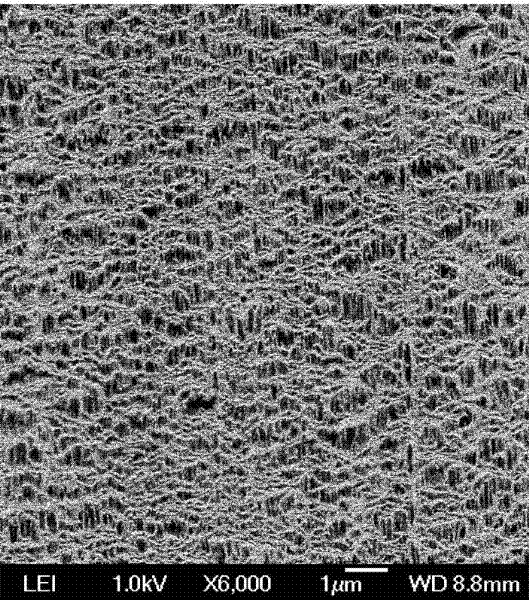

[0068] The selected molecular weight is 5.0 (Mn) × 10 -5 Polyethylene resin with a density of 0.966kg / m3 and a melt index of 1.08; the process flow is: melt spinning, cooling, winding, heat treatment, cold stretching, hot stretching, heat setting, and testing. After the polyethylene resin is melted, the polyethylene melt is extruded from the spinneret by the screw extruder, and stretched under the action of winding tension. The melt spinning temperature is 190°C in zone 1, 210°C in zone 2, and 225°C in zone 3; the spinning / drawing speed ratio is 4000; the cooling air height is 300mm, and the cooling air temperature is 10±5°C; the obtained polyethylene hollow fiber has micropores The membrane properties are as follows: porosity 75.1%, pore diameter 33.2nm, specific surface area 288.94m 2 / g, apparent density 0.699g / cm 3 , breaking strength 60.3MPa, N 2 Flux 47×103L / m 2 ·h·0.1MPa, the water flux is 220L / m 2 · h · 0.1MPa.

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com