A Method for Capturing Carbon Dioxide in Flue Gas Using Renewable Carbide Slag

A technology of carbon dioxide and carbide slag, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of low effective utilization rate of carbide slag, burial and stacking, and low environmental benefits, and achieve good pore structure and heat dissipation. Effects of stability, improvement of absorption efficiency, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

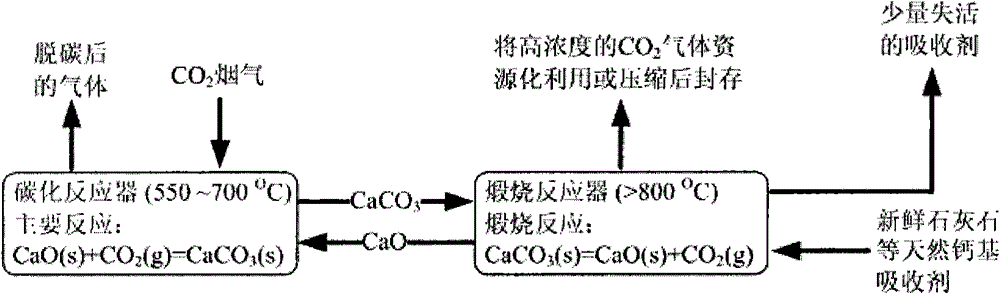

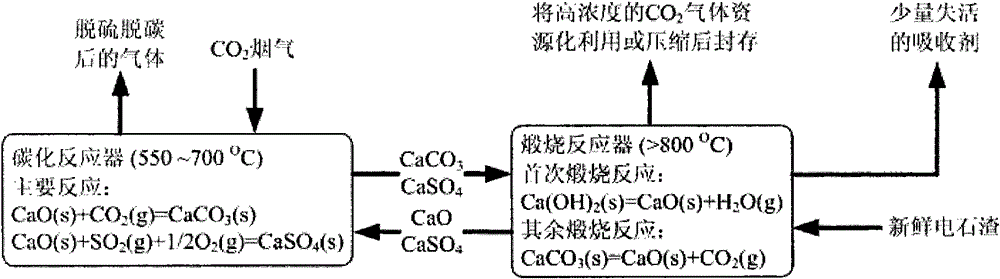

Method used

Image

Examples

Embodiment 1

[0030] Comparison of calcium carbide slag collected in a coal chemical plant with commercially available Ca(OH) using a fixed bed reactor 2 CO under low temperature calcination conditions 2 Absorptive properties. Carbide slag particle size: 160-180 mesh; calcination reaction temperature: 840℃; calcination time 10min; carbonization reaction temperature: 700℃; carbonization time: 20min; a total of 40 cycles of CO capture were investigated 2 (Note: the conversion of CaO in the absorbent is used to characterize CO 2 absorption efficiency). The results show that: (1) At the end of 40 cycles, the carbide slag and Ca(OH) 2 CO 2 The absorption efficiencies were 35.18% and 32.57%, respectively; (2) During the 40-cycle capture process, the calcium carbide slag and Ca(OH) 2 CO 2 The absorption efficiency attenuation coefficients are 0.16426 and 0.21140 respectively (the larger the attenuation coefficient is, the faster the attenuation speed is), thus indicating that: in ensuring th...

Embodiment 2

[0032] A fixed bed reactor was used to compare the CO concentration of carbide slag collected from a coal chemical plant and commercial limestone under low temperature calcination conditions 2 Absorptive properties. Carbide slag particle size: 160-180 mesh; calcination reaction temperature: 840℃; calcination time 10min; carbonization reaction temperature: 700℃; carbonization time: 20min; a total of 40 cycles of CO capture were investigated 2 absorption efficiency. The results show that: (1) At the end of 40 cycles, the CO of carbide slag and limestone 2 The absorption efficiencies were 35.18% and 26.22%, respectively; (2) During 40 cycles, the average CO of carbide slag and limestone 2 The absorption efficiencies were 41.01% and 38.14%, respectively; (3) CO of carbide slag and limestone 2 The absorption efficiency attenuation coefficients are 0.16426 and 0.28030, respectively, thus indicating that: in the guaranteed CO 2 Under the premise of absorption efficiency, carbide ...

Embodiment 3

[0034] A fixed bed reactor was used to compare the CO concentration of carbide slag collected from a coal chemical plant and commercial limestone at higher calcination temperatures 2 Absorptive properties. Carbide slag particle size: 160-180 mesh; calcination reaction temperature: 940℃; calcination time 10min; carbonization reaction temperature: 700℃; carbonization time: 20min; a total of 20 cycles of CO capture were investigated 2 absorption efficiency. The results show that: (1) the CO concentration of carbide slag and limestone at the end of 20 cycles 2 The absorption efficiencies were 28.30% and 22.53%, respectively; (2) During the 20-cycle capture process, the CO of carbide slag and limestone 2 The attenuation coefficients of absorption efficiency are 0.23958 and 0.39961, respectively, thus indicating that: for high temperature calcination conditions, carbide slag is effective against CO 2 The attenuation of absorption efficiency is also less than that of commercial li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com