Preparation process of glutamine enteric microcapsules

A glutamine sausage preparation technology, which is applied in the direction of microcapsules, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of patients taking inconvenience and adverse reactions, and achieve easy-to-obtain, Fast dissolution to reduce translocation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in one step in combination with specific embodiments.

[0012] 1. Choose suitable materials and optimize the coating prescription.

[0013] A. Determination of the solubility of excipients

[0014] Under the condition of 37℃, dissolve polyacrylic resin in 50ml of methanol and acetone. The volume ratio of methanol and acetone is 1:5. After the dissolution is completed, add a certain amount of polyacrylic resin until it is no longer Until it dissolves. It was measured that 0.3 g of polyacrylic resin was dissolved in 6.0 ml of mixed solvent.

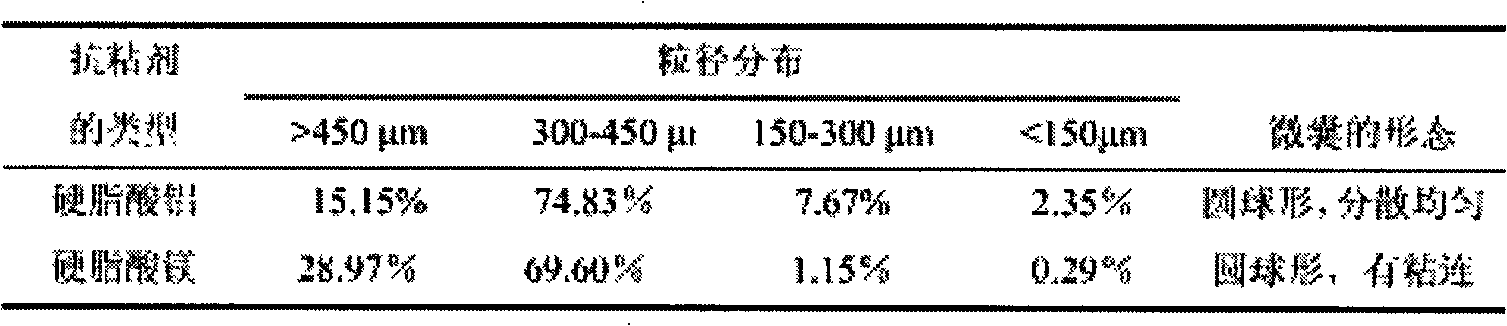

[0015] B. Choice of anti-adhesive

[0016] When preparing the microcapsules, the addition of a binder can keep the dispersed droplets in a stable form. Different anti-adhesive aluminum stearate and magnesium stearate are selected to prepare microcapsules and different dosages and compare them. See Table 1 below.

[0017] Table 1 The influence of choosing different anti-adhesive types on ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com