Para-aminosalicylic acid sustained-release pellet with high drug-loading rate and enteric-coated preparation thereof

A technology of para-aminosalicylic acid and sustained-release pellets, which is applied in the fields of para-aminosalicylic acid sustained-release enteric-coated oral preparations, high-loaded sustained-release pellets and their preparations, and can solve the waste of raw materials, strips Problems such as poor deformation ability and weak strips can achieve the effects of reducing production costs, improving formability and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

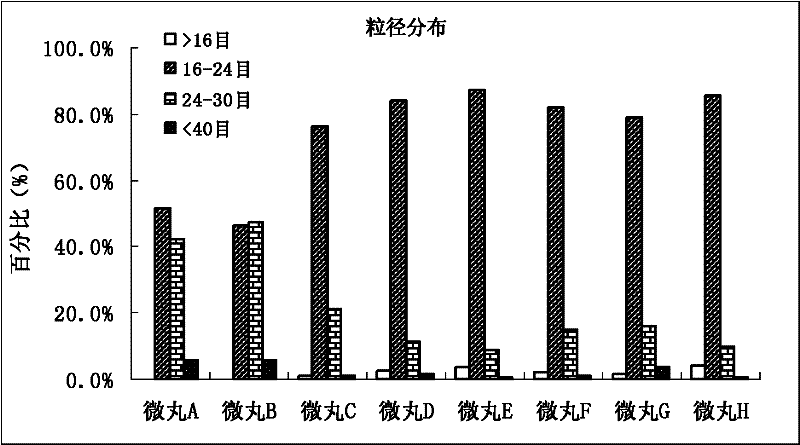

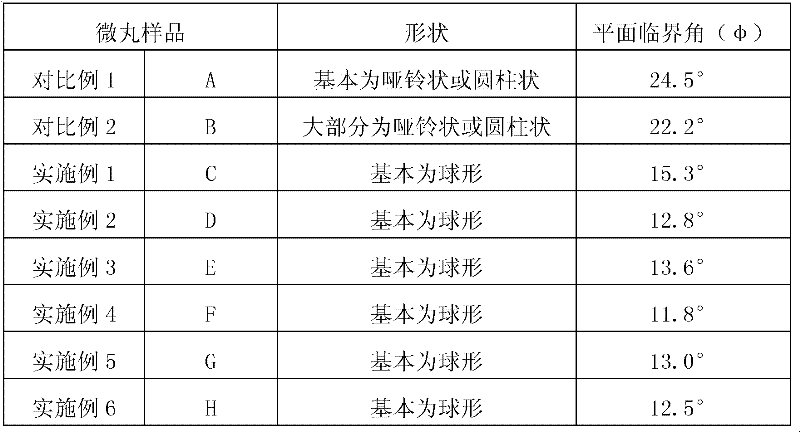

[0076] 1. Pellet C

[0077] Material

Proportion(%)

Weight (g)

p-aminosalicylic acid

70.0

350.0

25.0

125.0

3.0

15.0

2.0

10.0

total

100.0

500.0

[0078] After weighing p-aminosalicylic acid, microcrystalline cellulose, croscarmellose sodium and hydroxypropylmethyl cellulose and mixing them uniformly through a 80-mesh sieve according to the formula, add 300g of purified water (the soft material made by this material) The maximum amount that can be added) makes soft materials. Prepare drug-containing micropills by the method of Comparative Example 1 to obtain micropills C.

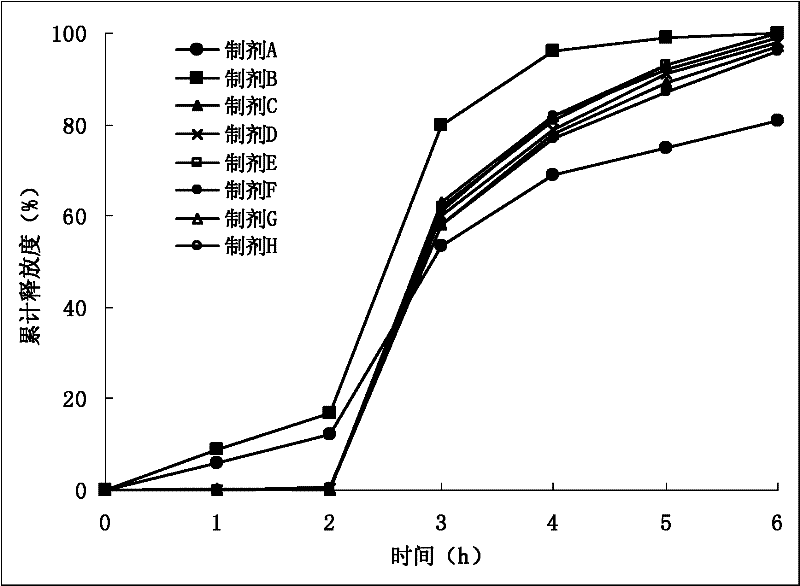

[0079] 2. Preparation C

[0080] Configure the coating liquid by the coating formula of comparative example 1, and get 16~24 mesh pellets C 200g after coating by the method of comparative example 1, fill in the medicinal composi...

Embodiment 2

[0082] 1. Pellet D (changed the proportion of water-absorbing material and the type of binder)

[0083] Material

[0084] According to the formula, p-aminosalicylic acid, microcrystalline cellulose, croscarmellose sodium and carboxymethyl cellulose sodium were weighed through an 80-mesh sieve and mixed evenly, and then 350 g of purified water was added to make a soft material. Prepare drug-containing micropills by the method of Example 1, and obtain micropills D.

[0085] 2. Preparation D (the coating formula has been changed)

[0086] Material

[0087] Weigh the polyacrylic resin II according to the formula, add 315g of 95% ethanol, dissolve it completely in a water bath at 60°C, add triethyl citrate and talcum powder, and stir evenly to obtain an enteric coating solution. Take 16-24 mesh pellets D 200g and place them in a multi-functional granulation coating machine, adjust the air volume and spray speed, control the temperature for coating at 35-39°C,...

Embodiment 3

[0089] 1. Pellet E (change the proportion of water-absorbing material and the type of binder)

[0090] Material

[0091] Take p-aminosalicylic acid, microcrystalline cellulose, croscarmellose sodium and polyvinylpyrrolidone according to the formula and mix them uniformly, then add 350 g of purified water to make a soft material. Prepare drug-containing micropills by the method of Comparative Example 1, and obtain micropills E.

[0092] 2. Preparation E (change the coating formula)

[0093] Material

[0094] Weigh Eudragit L100 according to the formula, add 315g of 95% ethanol, dissolve it completely in a water bath at 60°C, add triethyl citrate and talcum powder, and stir evenly to obtain an enteric coating solution. Take 16-24 mesh pellets E 200g and place them in a multi-functional granulation coating machine, adjust the air volume and spray speed, control the temperature for coating at 35-39°C, stop coating when the coating weight increases by 10%, 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com