Needled jacquard carpet and processing method thereof

A processing method and technology for carpets, applied in the direction of carpets, etc., to achieve the effects of wide gram weight range, high processing efficiency, and shortened travel distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Gray cloth: the gram weight is less than or equal to 1100 g / m 2 non-woven carpet

[0025] Flower shape: large flower shape

[0026] Equipment: SXT-420C multifunctional computerized jacquard combined machine produced by our company, including 1 unwinder, 1 tension frame, 1 computerized jacquard machine, 1 winder, 1 large vertical cabinet electric control box, vertical There is one operating table for the flat cabinet; driven by a servo motor, it is stable and without gaps; it is controlled by PLC and has a man-machine exchange interface, so the operation is simple and reliable.

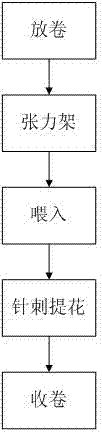

[0027] Process: unwinding→tension frame→feeding→acupuncture jacquard: set the pattern data, the interval time between solid and empty pricking actions, that is, the interval between forward and reverse rotation of the computer jacquard auxiliary shaft: 0.3 seconds, needle Pricking depth: up to 15mm, cloth output: 5.5 meters per minute. → Winding

[0028] Forming: the splicing distance error ...

Embodiment 2

[0030] Gray cloth: the weight is 500 g / m 2 base cloth carpet

[0031] Flower shape: small flower shape

[0032] Equipment: SXT-420C multifunctional computer jacquard combining machine produced by our company

[0033] Process: unwinding→tension frame→feeding→acupuncture jacquard: set the pattern data, the interval time between solid needle and empty needle action conversion, that is, the interval time between forward rotation and reverse rotation of the computer jacquard auxiliary shaft: 0.2 seconds, needle Pricking depth: up to 15mm, cloth output: less than or equal to 5 meters per minute. → Winding

[0034] Forming: the splicing distance error between the processed carpet flower shape and the flower shape is ≤0.1mm, and the depth error of the flower shape is ≤0.05mm.

Embodiment 3

[0036] Gray cloth: the weight is 300 g / m 2 base cloth carpet

[0037] Flower shape: stripes, corduroy, full velvet

[0038] Equipment: SXT-420C multifunctional computer jacquard combining machine produced by our company

[0039] Process: unwinding→tension frame→feeding→acupuncture jacquard: set the pattern data, the interval time between solid needle and empty needle action conversion, that is, the interval time between forward rotation and reverse rotation of the computer jacquard auxiliary shaft: 0.1 seconds, needle Pricking depth: 8-15mm, cloth output: less than or equal to 4 meters per minute. → Winding

[0040] Forming: the splicing distance error between the processed carpet flower shape and the flower shape is ≤0.1mm, and the depth error of the flower shape is ≤0.05mm.

[0041] The processing method of needle-punched jacquard carpet disclosed by the present invention is driven by a servo motor, is stable and has no gap, and successfully realizes the consistency of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com