Method for quenching small-size No. 45 steel parts

A technology of small size and parts, applied in the field of steel quenching, can solve the problems of unsatisfactory actual effect, difficult operation difficulty, quenching cracking problem, etc., achieve the effect of small deformation, good hardness consistency, and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

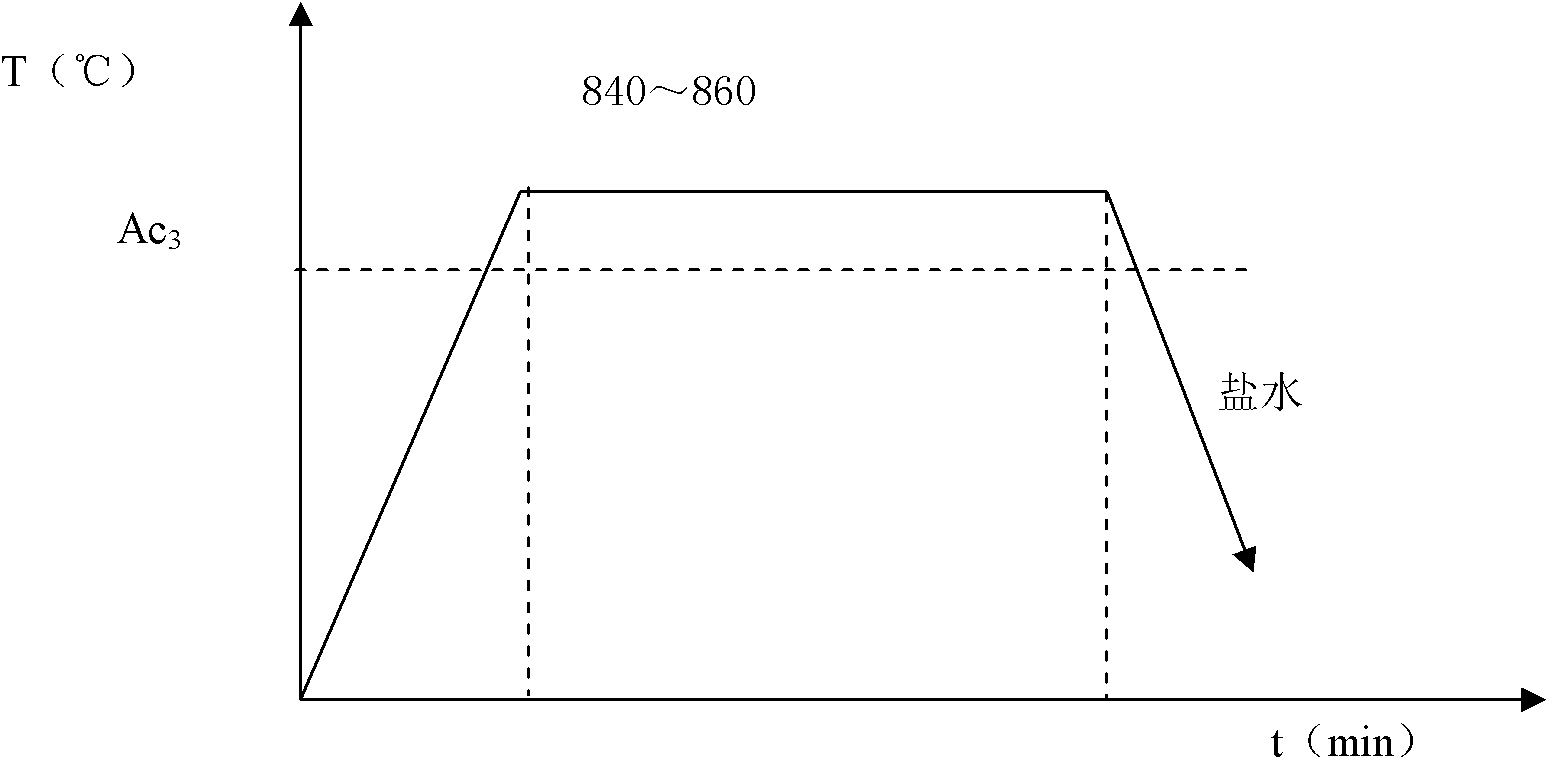

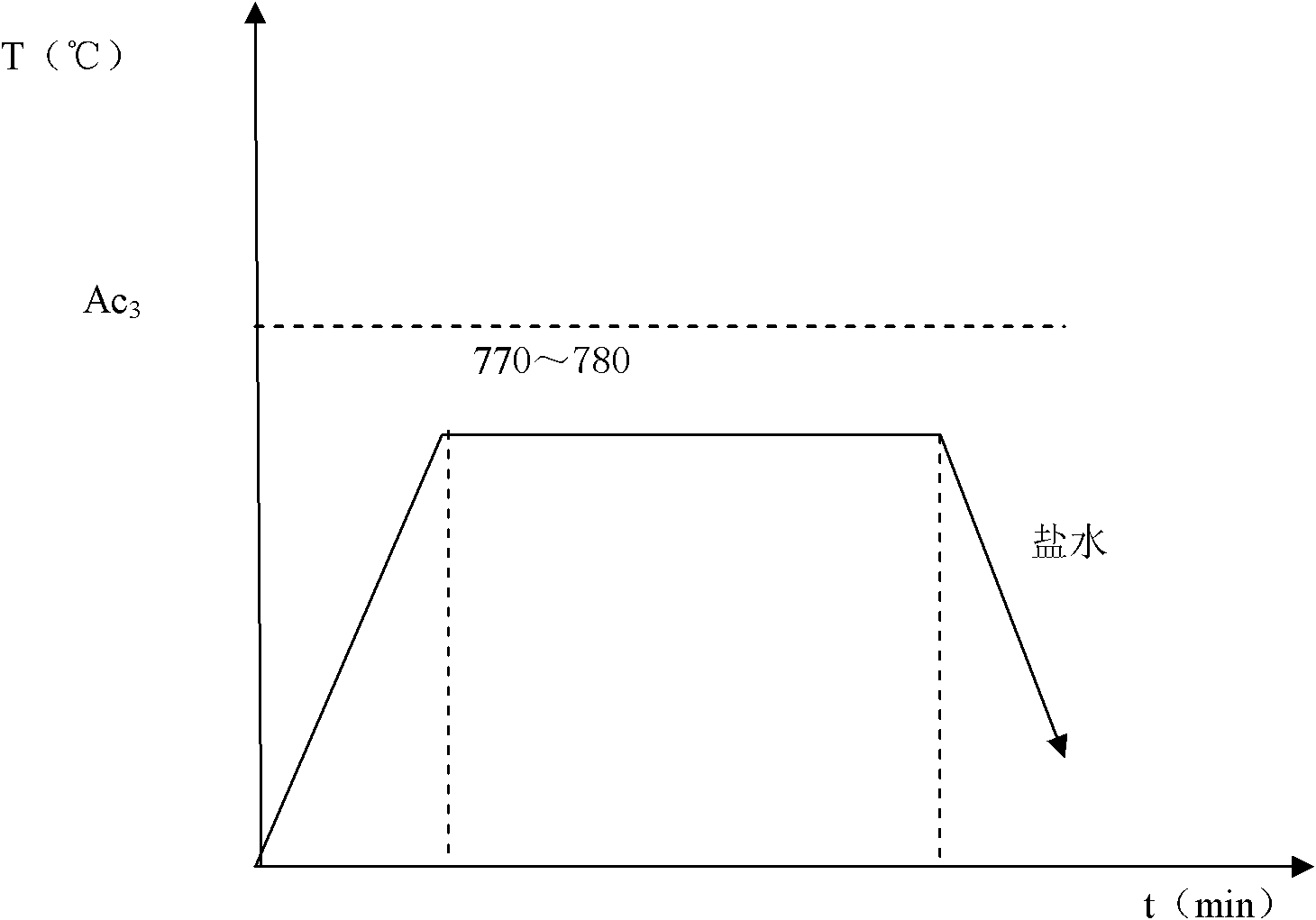

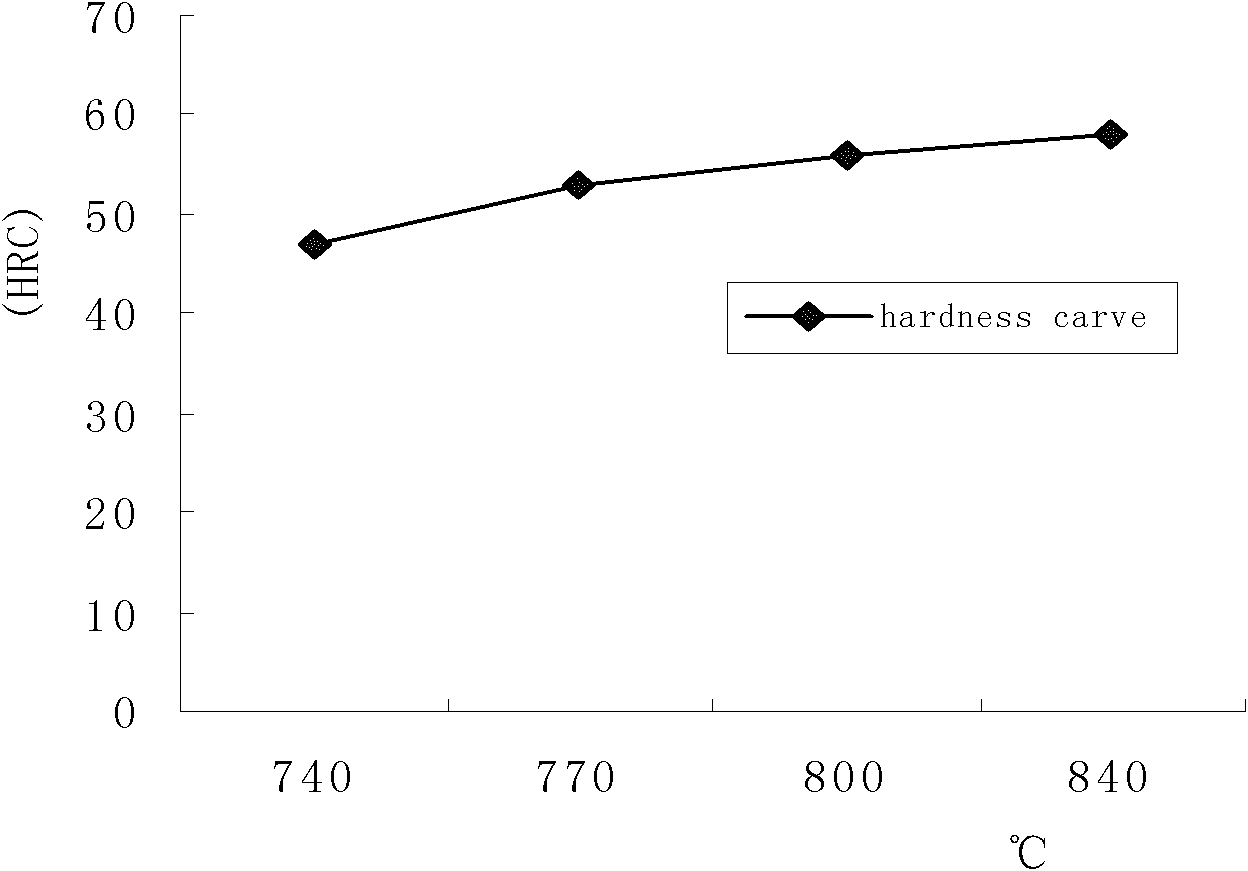

[0021] see figure 2 , the present invention provides a quenching method for small-sized parts of 45# steel - sub-temperature quenching. The method includes the following steps: heating and heat preservation at 770-780°C, quenching in salt water, tempering at 500-540°C, especially tempering at 520°C (HRC28~32). See Table 1. The new method reduces one rough turning process and one annealing treatment method, saves energy and reduces consumption, and is easy to operate. It solves the problem of quenching cracking of cold-drawn 45# steel and achieves good results.

[0022] Table 1 Comparison of new and old processing methods for 45# steel

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com