Concentric filtering bar formed by mixing tow and paper as well as preparation and application methods thereof

A technology of hybrid molding and filter rods, which is applied in applications, e-liquid filter elements, tobacco, etc., can solve the problems of cost increase and the lack of conditions for simultaneous molding of multiple fibers, and achieve cost reduction, good coke reduction and harm reduction effects, The effect of saving the cost of equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

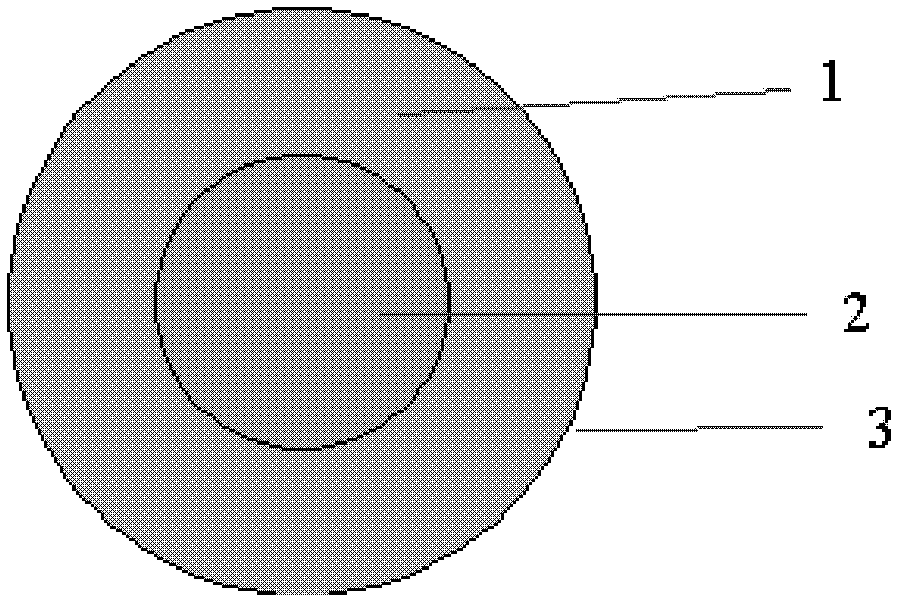

[0027] see figure 1 , In this embodiment, the filter rod is composed of an outer core 1 and an inner core 2, and the outer core is wrapped with ordinary or high-permeability molding paper 3. The 3.0 / 32000 acetate fiber tow is pre-opened on the nozzle rod forming machine according to the conventional production method of acetate fiber filter rod, and triacetin is applied, and sent to the output roller; no triacetin is applied after the paper nozzle rod is opened , fed at the position of the output roller and the acetate fiber passes through the output roller synchronously, and is sent to the circular tube sleeve together. The paper shrinks into a circle after passing through the circular tube sleeve, and the tow goes outside the sleeve. After the two pass through the sleeve, the tow Wrapped on the outside of the cylindrical paper, it enters the bong to be formed and cut to make a new type of concentric filter rod whose inner core is paper and outer core is acetate fiber tow. T...

Embodiment 2

[0031] The 3.0 / 32000 acetate fiber tow is pre-opened on the nozzle rod forming machine according to the conventional production method of acetate fiber filter rod, and triacetin is applied, and sent to the output roller; no triacetin is applied after the paper nozzle rod is opened , fed at the position of the output roller and the acetate fiber passes through the output roller synchronously, and is sent to the circular tube sleeve together. The acetate tow is shrunk into a circle through the inside of the circular tube sleeve, and the paper goes outside the sleeve. After the two pass through the sleeve The paper is wrapped on the outer side of the cylindrical cellulose acetate tow and enters the bong for molding and cutting to make a new type of concentric filter rod whose inner core is cellulose acetate tow and the outer core is paper. The new filter stick prepared is directly used in cigarettes, which can reduce tar by 1.44mg / cigarette compared with the control sample. The s...

Embodiment 3

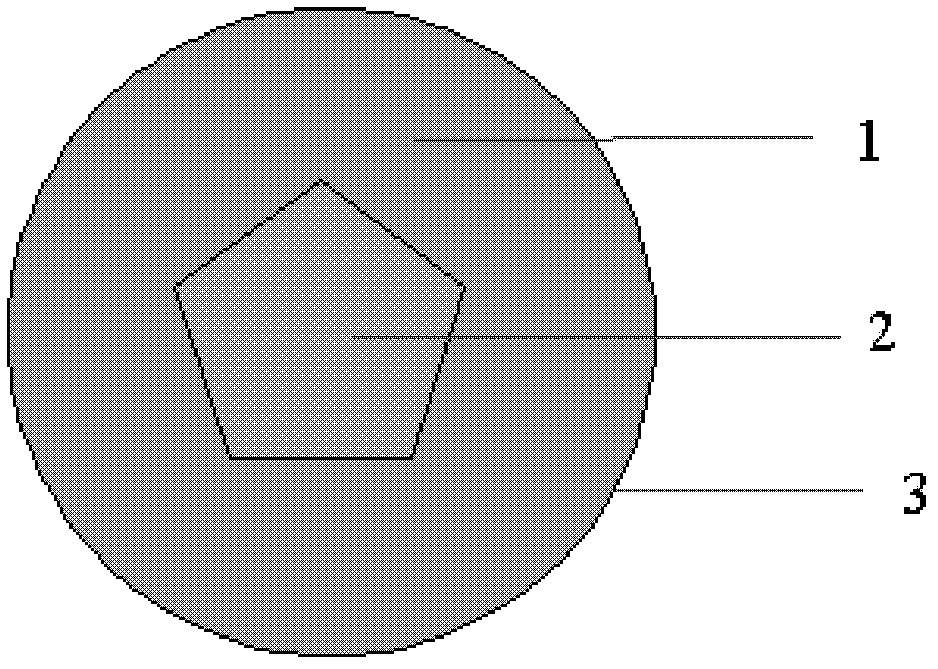

[0035] see figure 2 , In this embodiment, the filter rod is composed of an outer core 1 and an inner core 2, and the outer core is wrapped with ordinary or high-permeability molding paper 3. The outer core is ordinary acetate fiber, the inner core is paper wood pulp fiber, and the end face is regular pentagon; or the outer core is paper wood pulp fiber, the inner core is ordinary acetate fiber, and the end face is regular pentagon. The preparation method is the same as in Example 1 or 2, except that the inner core is formed without a circular tube sleeve, but with a regular pentagonal sleeve; the end face of this filter rod has a novel shape, and the pressure difference between the outer core and the inner core is inconsistent. The performance of the filter material is inconsistent, which can more effectively absorb the amount of tar in the flue gas. The new filter stick prepared is directly used in cigarettes, which can reduce tar by 2.7mg / cigarette compared with the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com