Automatic optical inspection method and automatic optical inspection equipment

An automatic optical inspection, optical automatic inspection technology, applied in the direction of optical testing flaws/defects, optics, nonlinear optics, etc., can solve the problems of high price, high cost, large amount of information, etc., to achieve repeatability and speed increase, reduce requirements, the effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0026] An optical automatic detection device of the present invention includes a photography device for acquiring grayscale information of an image of an object to be inspected, and a computing module for receiving the grayscale information and generating a standard image for automatic optical detection. The automatic optical detection method of the optical automatic detection equipment can be applied to the detection of liquid crystal substrates, surface mount technology (Surface Mounted Technology, SMT) and other products. In this embodiment, the liquid crystal substrates applied to them are taken as examples for illustration.

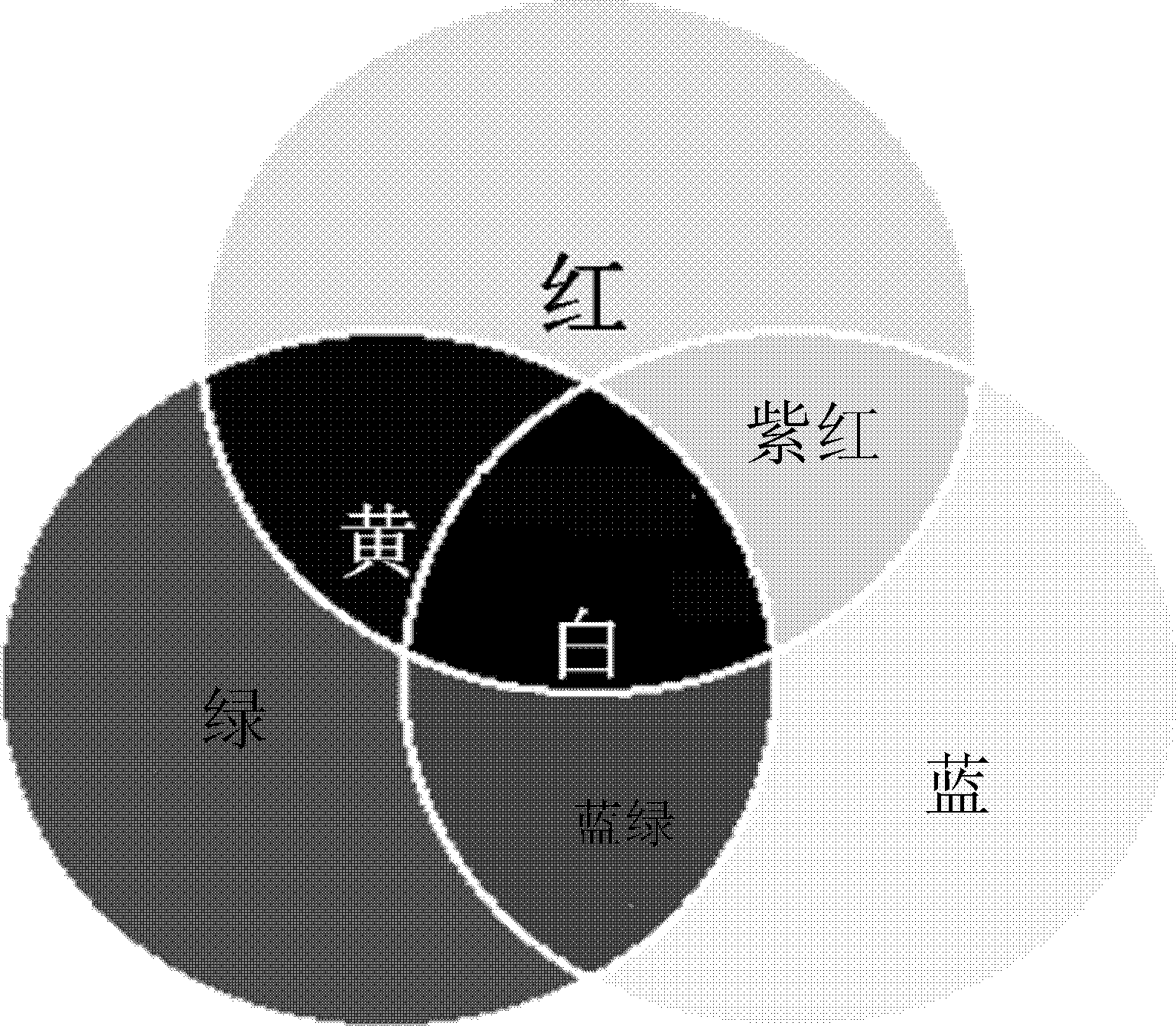

[0027] The manufacturing process of the TFT-LCD includes an array process (Array) and a color filter process (Color Filter, CF, color filter plate). The graphics in the array process and the color filter process are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com