Lens drive device, spring member and manufacturing methods thereof

A technology of a lens driving device and a spring component, which is applied in the field of spring components, can solve problems such as difficulty in controlling the spring constant, and achieve the effects of preventing the design space from being narrowed, improving reliability, and promoting thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The best mode for carrying out the present invention will be described below with reference to the drawings.

[0080] [Mechanical structure]

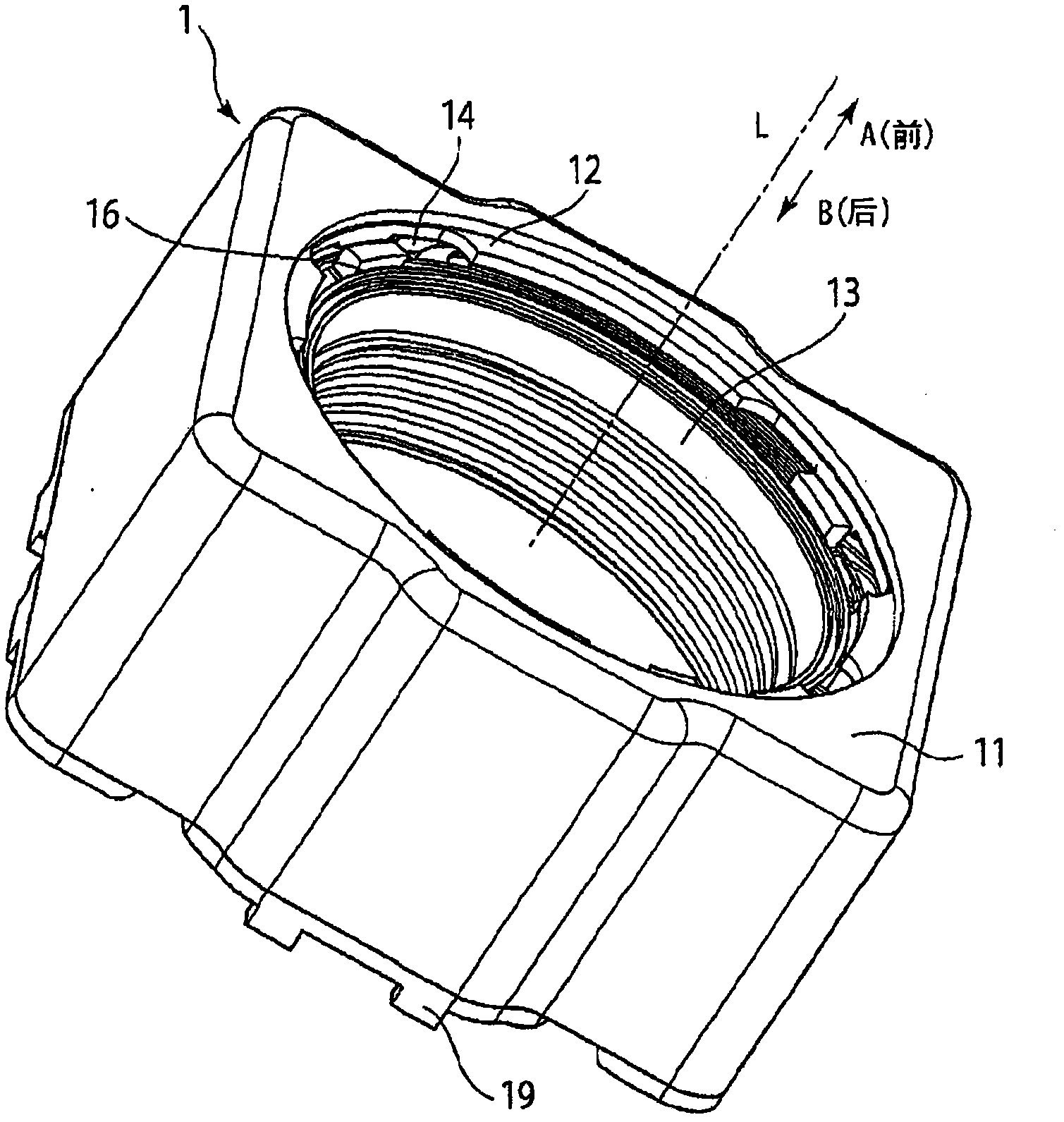

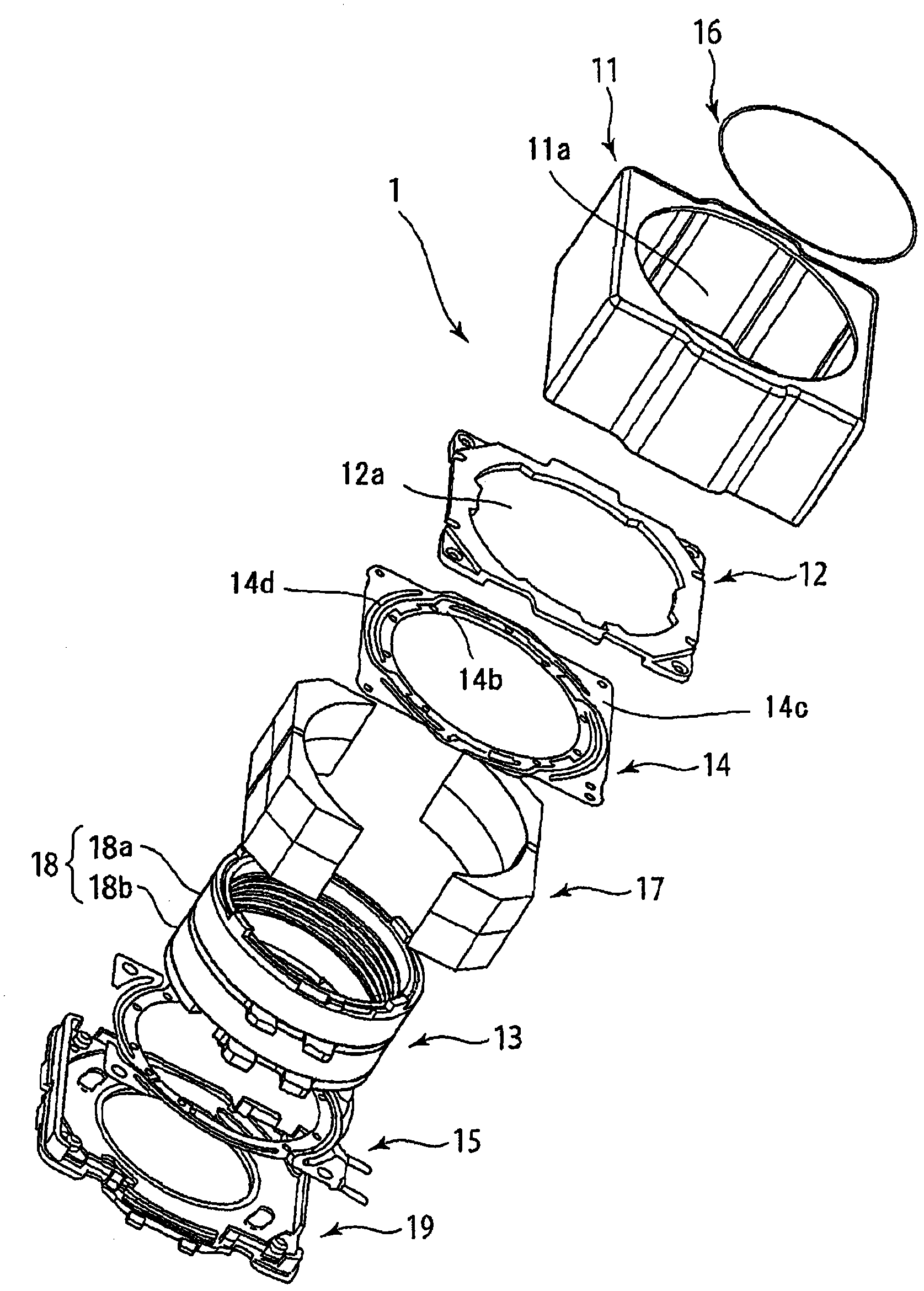

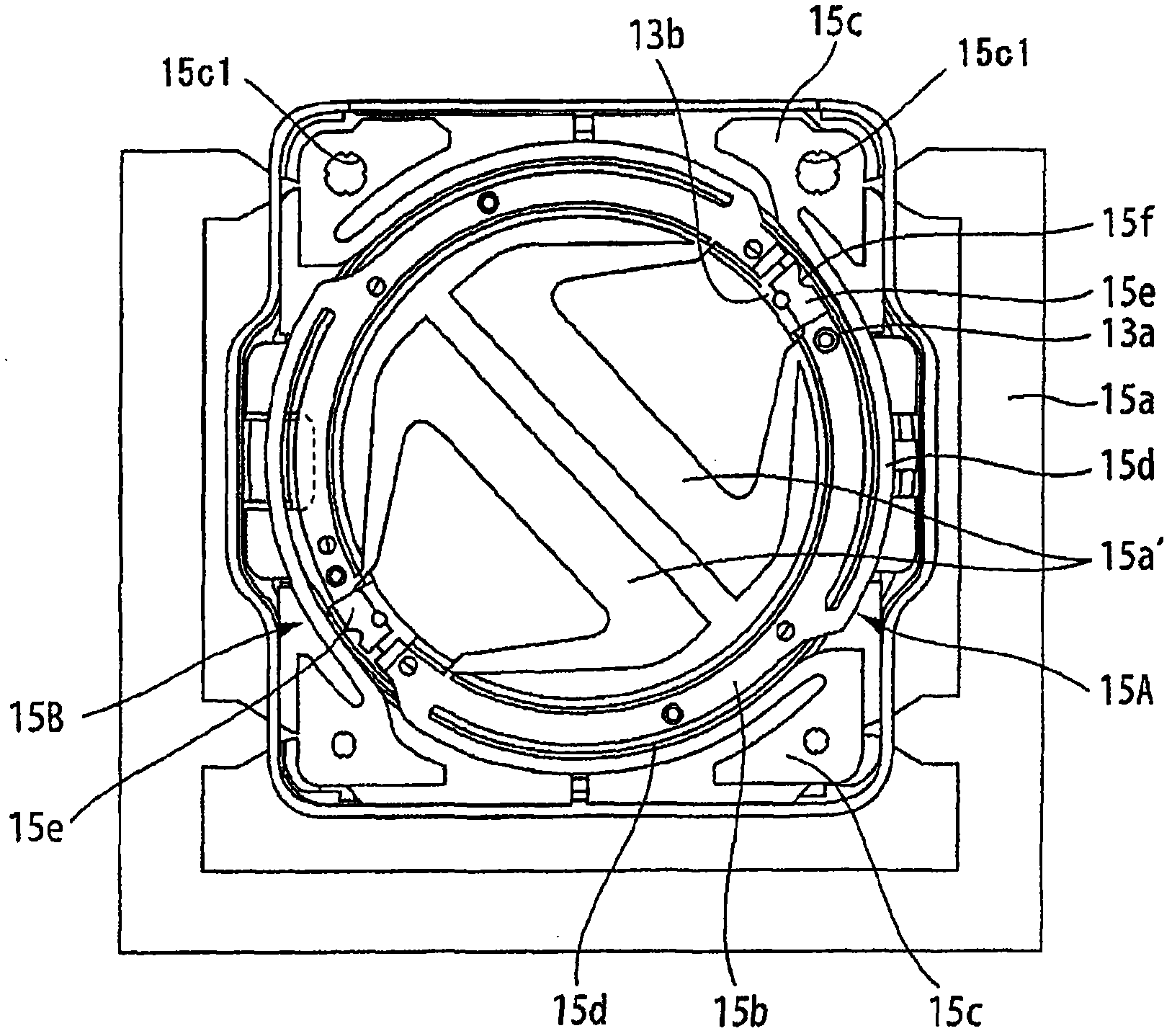

[0081] figure 1 It is a perspective view showing the external structure of the lens driving device 1 according to the embodiment of the present invention. figure 2 It is an exploded perspective view showing the mechanical structure of the lens driving device 1 according to the embodiment of the present invention.

[0082] exist figure 1 and figure 2 Among them, the lens driving device 1 has: a yoke 11, a cover 12, a sleeve 13, a first leaf spring 14, a second leaf spring 15, a wire spring 16, a magnet 17, a coil 18 (the first coil 18a and the second coil 18b ), and holder 19.

[0083] In addition, the lens barrel on which the lens is mounted is not shown. The lens driving device 1 directs the sleeve 13 toward the A direction (front side) close to the object (image-taking object) and the B direction (rear side) close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com