Water-cooled electrode of high temperature vacuum furnace

A high-temperature vacuum, water-cooled electrode technology, used in furnaces, electric furnace heating, furnace components, etc., can solve the problems of aging and failure of O-ring seals, insulation failure, and inability to ensure vacuum sealing, and achieve the effect of increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

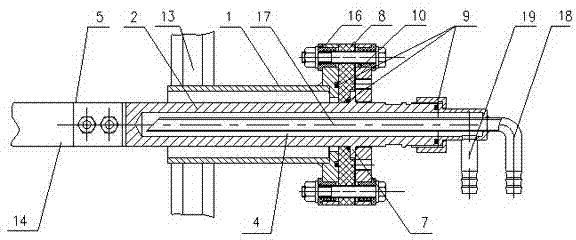

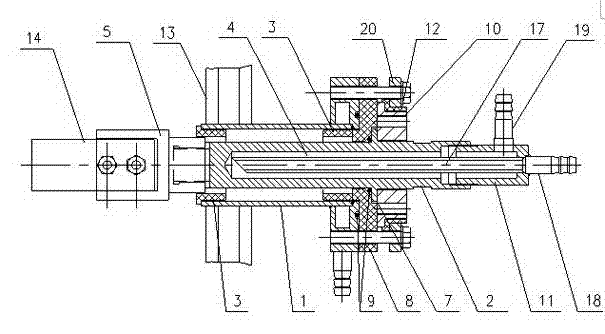

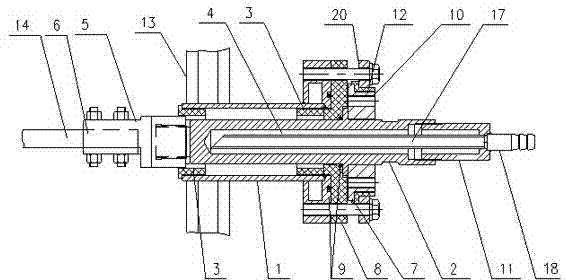

[0025] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 2-5 As shown, a water-cooled electrode of a high-temperature vacuum furnace includes an electrode holder 1 with a through hole in the middle. The electrode holder 1 is welded by a cylinder 101 and a base 102. The base 102 is provided with a cooling water tank 103 and a water inlet 104 and The water outlet 105 is provided with ceramic collars 3 respectively at the two ends of the through hole of the electrode holder between the electrode rod 2 and the electrode holder 1 . The electrode holder 1 is pierced with an electrode rod 2, and the electrode rod 2 is provided with a ring-shaped installation boss 7. An insulating flange 8 is arranged between the base 102 of the electrode holder 1 and the ring-shaped installation boss 7 of the electrode rod 2. The insulation method A sealing ring 9 is provided on the contact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com