Composite inorganic fireproof board and preparation method for same

An inorganic fireproof board and inorganic adhesive technology, applied in fire prevention, building components, building materials and other directions, can solve the problems of not complying with energy saving and emission reduction, increase the weight of the board, increase the thickness and density, etc. Simple preparation process and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

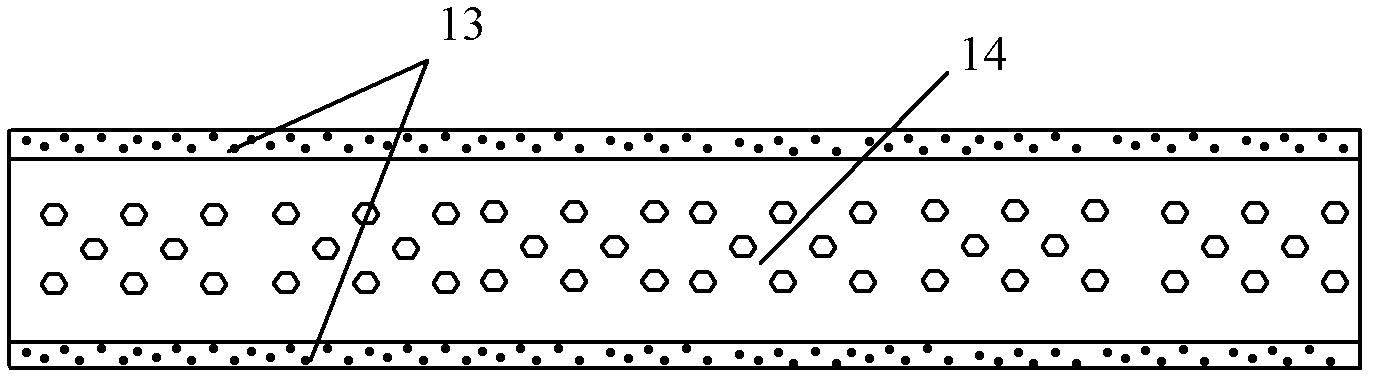

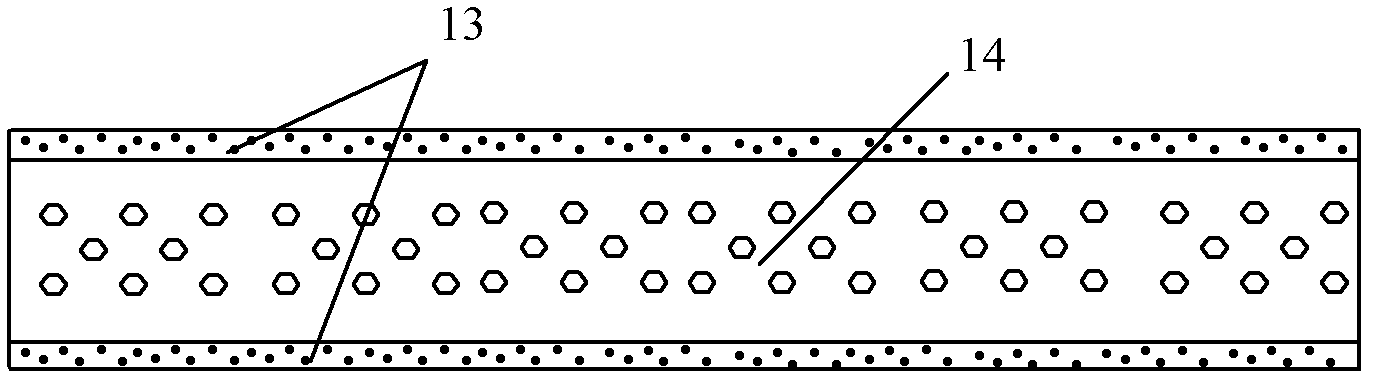

[0027] Example: Composite inorganic fireproof board, such as figure 1 As shown, it includes a heat-insulating core layer 14, and strength structure layers 13 respectively compounded on both surfaces of the heat-insulating core layer. The heat insulation core layer is a layered structure made of inorganic adhesive as gelling agent, thermal insulation material as filler, and colloidal configuration; into a layered structure.

[0028] Preferably: the strength structure layer is added with performance supplementary materials, which are used to increase the bending strength and / or reduce the weight. Of course, for performance supplementary materials, it is effective to add, not add, or add less. Preferred options for performance supplementary materials: fiber materials and / or lightweight materials. Among them, lightweight fillers include: wood powder (bamboo powder), expanded vermiculite, expanded perlite, floating beads, diatomaceous earth, etc. Fiber materials include: orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com