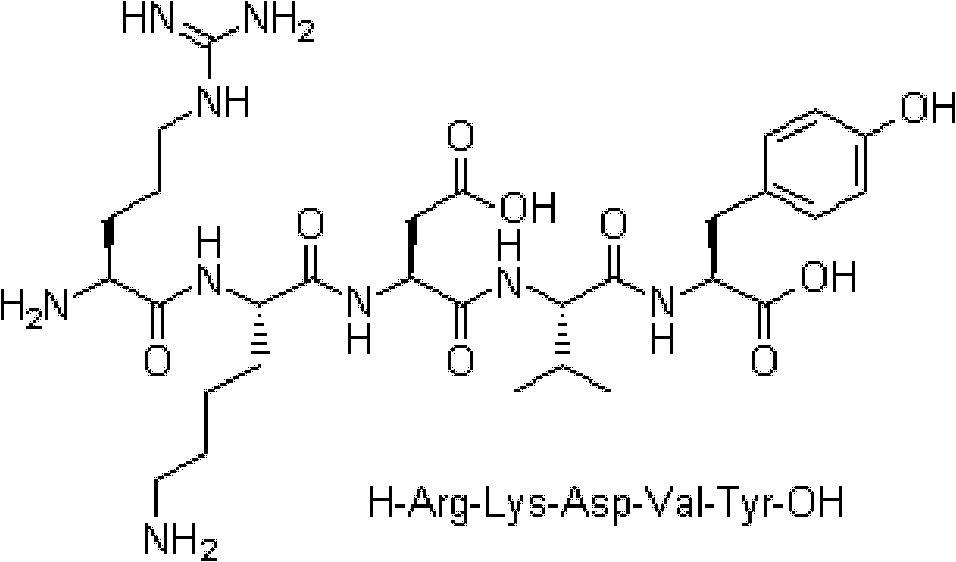

Method for preparing thymopentin

A technology of thymus and resin, which is applied in the field of preparation of polypeptide drugs, can solve the problems of unfavorable industrialization prospects, cumbersome operation, and expensive palladium carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Self-made polypeptide solid-phase synthesis reactor

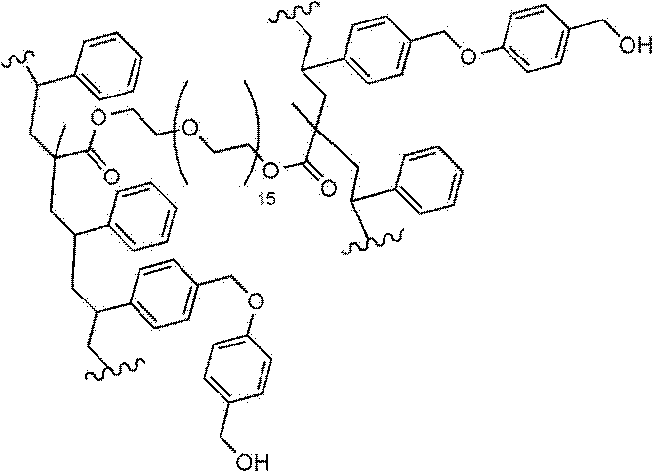

[0047] After preparing PEG-wang resin-Tyr(tbu)-OH according to step 1 of the above-mentioned content of the invention, prepare thymopentin crude product according to step 2 of the content of the invention: take the prepared PEG-wang resin-Tyr(tbu)-OH, add Into the reaction vessel, add 2000 ml of DMF to wash once, add 2000 ml of DMF to soak for 60 minutes, add 2000 ml of DCM to wash once. Add 2000 ml of 20% hexahydropyridine in DMF and wash twice for 5 minutes each time. Wash 3 times with 1000 mL DMF, 2 times with 1000 mL ethanol, and 2 times with 1000 mL DCM. Then add 5g superabsorbent resin (KL150-300A type, Nantong Keli Water Absorbent Resin Co., Ltd.), dissolve 240 millimoles of Fmoc-Val-OH in 1000 milliliters of DCM / DMF (volume ratio is 4: 1) and stir Dissolve, add 600 mmol of HOBt, 1000 ml of DMF and stir, then add 360 mmol of DIC, stir and react for 10 minutes, add to the resin, stir and react for ...

Embodiment 2

[0050] After preparing PEG-wang resin-Tyr(tbu)-OH according to step 1 of the above-mentioned content of the invention, prepare thymopentin crude product according to step 2 of the content of the invention: take the prepared PEG-wang resin-Tyr(tbu)-OH, add Into the reaction vessel, add 2000 ml of DMF to wash once, add 2000 ml of DMF to soak for 60 minutes, add 2000 ml of DCM to wash once. Add 2000 ml of 20% hexahydropyridine in DMF and wash twice for 5 minutes each time. Wash 3 times with 1000 mL DMF, 2 times with 1000 mL ethanol, and 2 times with 1000 mL DCM. Then add 50g superabsorbent resin (KL150-300A type, Nantong Keli Water Absorbent Resin Co., Ltd.), dissolve 240 millimoles of Fmoc-Val-OH in 1000 milliliters of DCM / DMF (volume ratio is 1: 1) and stir Dissolve, add 600 mmol of HOBt, 1000 ml of DMF and stir, then add 360 mmol of DIC, stir and react for 10 minutes, add to the resin, stir and react for 1.5 h. Wash 3 times with 2000 ml DMF, 2 times with 2000 ml ethanol, and...

Embodiment 3

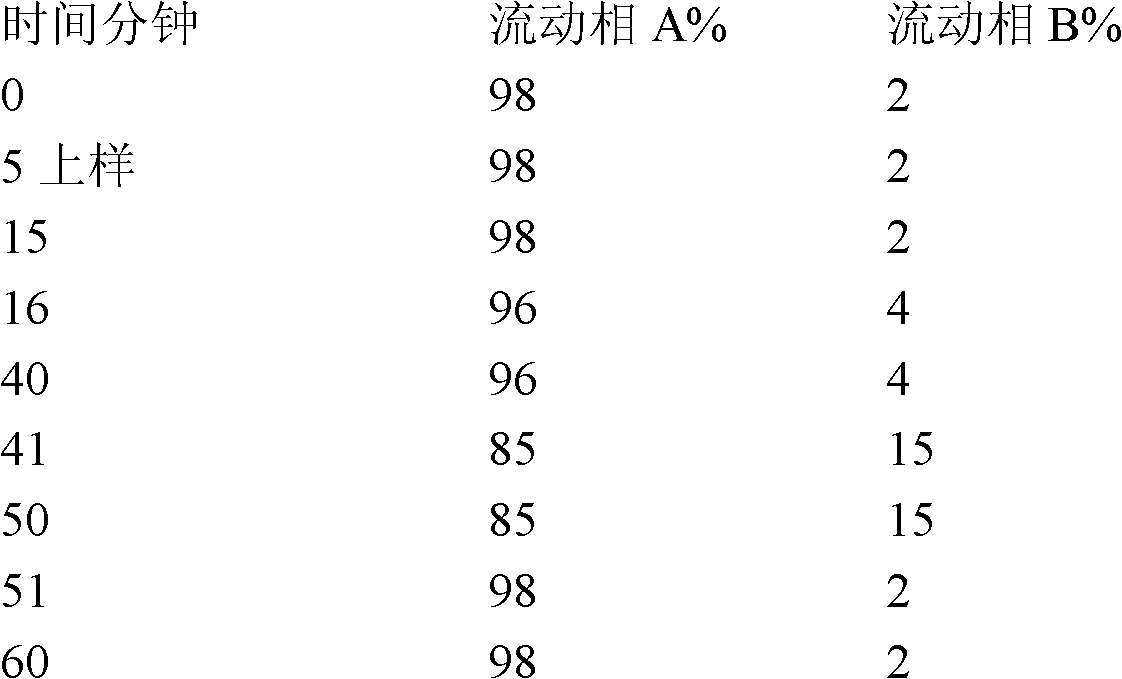

[0052] Embodiment 3: the HPLC identification of solid phase synthesis Thymopentin

[0053] RP-HPLC analysis to determine thymopentin:

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com